Warehouse Design

Originally published on December 19, 2018 by Logiwa Marketing, Updated on October 11, 2023

In this comprehensive guide to warehouse layout design, you’ll learn how to optimize your warehouse space for improved efficiency and productivity. We’ll take you through the essential phases of the project, from initiation to execution, planning, and closing. By the end of this read, you’ll be equipped with the knowledge and strategies needed to transform your warehouse into a well-organized and efficient operation.

Key Takeaways:

- Identify Warehouse Problems: Understand the critical issues in your warehouse, such as inefficient equipment placement, poor product placement, and disorganized flow of people and equipment.

- Utilize Technology: Use technology like Warehouse Management Systems (WMS) and data analysis to assess your warehouse’s current state and optimize its layout.

- Plan Carefully: Create a detailed plan, including a warehouse map, equipment needs, and budgets, and consider unique requirements for your business.

- Visualize with CAD: Consider computer-aided design (CAD) tools to create a visual representation of your ideal warehouse layout.

- Execute and Evaluate: Execute the redesign in phases, gather feedback, and assess lessons learned for continuous improvement.

Contents

- How Do I Start a Warehouse Layout Design Project?

- Initiation Phase: Identify the Problems You Want to Solve

- Planning Phase: Detail the Work to Be Done

- Execution Phase: Make Your Warehouse Design Plans a Reality

- Closing Phase: Gather Feedback, Assess Lessons Learned, and Plan for Further Enhancements

- Optimize Your Warehouse Layout for Success

Warehouse Layout Design

Your warehouse business is growing, but it seems like your operations just can’t keep up.

As you eye those pallets sitting in the aisle instead of on the racks and you watch workers and forklifts bottleneck in aisles and cause delays, you can’t help but think:

There’s got to be a better way to organize this place.

Designing – or redesigning – your warehouse layout is no frivolous task.

Optimizing your warehouse reduces the time it takes to complete each task. Streamlined tasks keep workers happy. Happy workers equals reduced absenteeism and greater productivity. Greater productivity equals efficient operations. And efficient operations equals happy customers, which leads to a profitable business.

Sounds like a pretty good return on investment to us.

How Do I Start a Warehouse Layout Design Project?

Understandably, revamping your entire warehouse operations sounds stressful. After all, a warehouse is massive by design, and you still have to keep your business running in the meantime. Take a deep breath, think about the future benefits, and let the following phases guide your warehouse layout redesign:

- Initiation Phase

- Planning Phase

- Implementation / Execution Phase

- Closing Phase

Altogether, these phases make up the project lifecycle, which is a proven way to keep large projects on track. Taking a project management approach to your warehouse layout redesign can make the job less intimidating by breaking it down into manageable tasks.

In fact, you may even want to use project management software to keep you on track. If you’re working with a warehouse layout consultant, they’ll have project management tips and software to help you out.

If you’re running this project on your own, consider project management technology like Microsoft Project, Workzone, and Clarizen.

Initiation Phase: Identify the Problems You Want to Solve

First step: identify the problem you’re trying to solve. If you simply rearrange a few shelves and clean up some work areas without a clearly defined objective, you’ll be disappointed with the results.

Think about the major problems within your warehouse. For instance, is your facility struggling with:

- Inefficient placement of equipment? If you consistently use one piece of equipment after another, but the two are located incredibly far away from each other, you’re wasting your workers’ time and your company’s resources. Inefficiencies are frustrating and tedious for workers who have to take twenty steps to handle a task that could be completed in four.

- Poor placement of products? If you follow the Pareto Principle, 80% of your warehouse movements come from 20% of your products. If this 20% of products is located in a hard-to-reach area of your warehouse or behind other goods, it’ll take your workers longer to store, pick, and pack fast-moving products.

- Disorganized flow of people and equipment? People and equipment are constantly moving through your warehouse, and bottlenecks or traffic jams can lead to missed deadlines, decreased productivity, injuries, and even deaths. A warehouse layout designed with a traffic management plan helps mitigate these risks.

Want to quickly understand where your warehouse’s challenges lie? You’ve got two main options.

Option 1: Hold Consultations

Consult with your warehouse workers to identify inefficiencies. There may be elements of your warehouse operations that you’d never considered a problem before, but that are actually causing undue stress for your workers. Addressing these concerns is important. One study shows that useless or inefficient tasks have a negative effect on the mental health of workers. If your warehouse layout can eliminate some of these concerns, it’s worth incorporating them into your plans.

Option 2: Use Technology to Assess Your Warehouse’s Current State

If your warehouse management system (WMS) uses mobile scanners or radio frequency identification (RFID) technology, you can readily assess your data to understand the flow of goods through your warehouse. This analysis will identify your most frequently moved goods, the areas with the most traffic in your warehouse, and how long it takes to store, pick, pack, and ship goods.

More specifically, you can understand your warehouse’s operations (and plan your layout redesign accordingly) using statistics from your WMS technology, like total landed cost.

Knowing the total landed cost of each item allows you to understand which particular items are driving your revenue. Conversely, you understand which items aren’t driving your revenue, allowing you to strategically reorganize your warehouse space so that fast-moving items are easily accessible and slow-moving items are placed in the less-convenient spots.

Planning Phase: Detail the Work to Be Done

In the planning phase, you outline the work to be done, the tasks and resources needed, and timeframes. By the end of this phase in your warehouse redesign project, you should have:

- Listed and described all the tasks to be completed

- Drafted the schedule

- Estimated the project costs

Create a Map of Your Warehouse

Once you’ve committed to specific areas of improvement, create a map of your warehouse. You can either use an existing map, manually draw a map, or use technology such as the warehouse layout and design software SmartDraw.

Whichever method you use, your map should clearly illustrate elements like:

- Docks doors

- Height restrictions

- Columns/supports

- Overhead doors

- Installed equipment

- Office areas (with indication of which direction the door opens to avoid blocking entrances/exits)

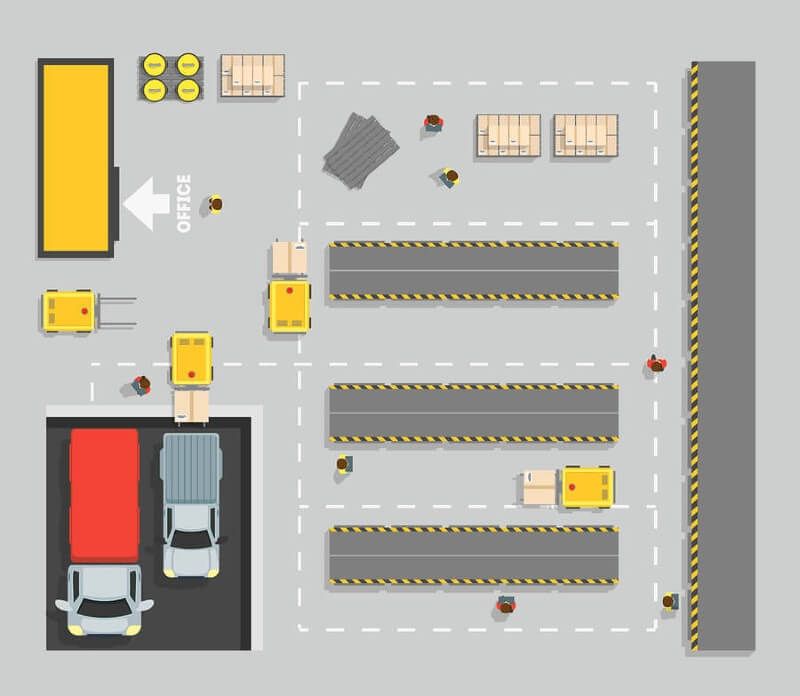

Furthermore, identify the operational locations of your warehouse on your map. Laying them out clearly will allow you to consider every movement and activity within your warehouse. Examples of operational activities include:

- Inbound staging area

- Back-to-back racks

- Packing desks

- Outbound shipment area

- Free areas

- Damaged product area

Consider The Unique Requirements of Your Warehouse

Your planning efforts will depend on your unique business. Generally, every warehouse layout redesign effort should consider the following elements:

- Equipment and Surrounding Workspace. As a warehouse, your key units may consist of items like pallet racks, shelving, and equipment.

- Production Zones and Workflow Areas. A warehouse manager needs to think about the space between shelves. Since your primary objective is receiving, stocking, and shipping, efficiently accessing goods is of the utmost importance. It should be easy for forklifts and people to navigate aisles. You’ll also want to plan a specific location for packing and receiving. Failing to allocate enough space for these essential, non-storage activities can lead to bottlenecks and damaged goods.

- Storage Areas. The types of items you store impacts your warehouse layout planning. If you’re moving pallets with pallet jacks or a forklift, you’ll need wider aisles and shelving. If your goods are hand-picked, you won’t need as much space. The type of items you’re storing also impacts the type of shelving you purchase, so be mindful of any particular requirements related to safety (e.g. chemicals) or temperature (e.g. perishable goods) when deciding where to store certain goods.

Add Your Warehouse Flow to Your Map

Start by listing your key processes, and then draw the workflow directions of those operations. Use different colors – either on paper or in your software – to draw the secondary operations that follow these main processes.

Use your earlier conversations with warehouse workers or the information from your WMS to create an accurate representation of the different workflows.

Overall, your planning should account for these 6 basic warehouse workflows:

- The putaway flow from the inbound receiving area to back-to-back racks or free areas

- The walking paths and directions for the pickers

- The picking path or direction for the forklift drivers

- The outbound flow for picked orders

- The movement of returned products to the damaged area or inventory

- The flow of packed and labeled boxes to outbound shipment area

Analyze Your Warehouse Map and Consider Opportunities to Optimize

Carefully analyze the data on operational locations, shipping, receiving, assembly, special handling lines, and quality and inspection areas along with the warehouse flow you have drawn. Clear product and location identification are critical to receiving, picking, and putaway efficiency and accuracy.

Storage area and staging lane identification is another must. Go through your notes on inbound and outbound operations and value-added processes with your team and make sure nothing is missing. Keep in mind that even relatively minor activities can dramatically affect warehouse efficiency. So be sure you’ve covered all of the locations and operations in your warehouse.

While analyzing your data, or circling back to your team, use this general checklist to ensure you’ve covered all bases:

- Diagrammed every possible movement in your warehouse

- Highlighted the main paths (those with the most movements)

- Reserved enough space for forklift movements

- Partitioned off a multi-purpose free area for staging, moving, etc.

- Created separate locations for inbound shipments and outbound shipments (if possible)

- Reserved the first 2 levels of back-to-back racks for pickers

- Created a dedicated space for damaged items

- Considered smaller shelves for small items (if applicable)

- Considered drawers for smaller items which cannot be barcoded (unless implementing RFID technology)

Once you’ve identified priority areas for optimization, you can start making a shopping list and budget for your revamped warehouse.

Use Computer-Aided Design (CAD) to Visualize Your Ideal Warehouse Layout

Depending on your comfort level with technology and your budget, you can use computer-aided design (CAD) tools to design the optimal warehouse layout.

The use of CAD tools in warehouse applications—where designers could assess various layout options including “building shape, equipment selection, and operational conditions”—is still emerging, and most commercially available tools are not specifically designed for warehouses.

As a result, warehouse designers who want to build photorealistic, 3D renderings of their warehouses need experience working in software like AutoCAD or the willingness to tackle the steep learning curve.

Alternatively, warehouse managers can use basic sketching tools, like SketchUp, to create 3D models of their dream warehouse and even realistic 3D renderings.

If you hire a warehouse design consultant, they will likely be able to create photorealistic 3D models for you.

Draft a List of Required Equipment and Associated Costs

Depending on the scope of your warehouse layout design, you may need to simply move a couple things around, add some new equipment, or buy everything new, including:

- Pallet racks

- Industrial shelving

- Cantilever racks

- Flow racks

- Forklifts

- Pallet jacks

- Hand trucks

- Service carts

- Dock plates/boards

- Yard ramps

Once you’ve made a list of desired equipment, assign prices and list them in order of importance so you can focus your budget on high-priority items.

Maybe your layout design project’s objective is to modernize and automate your current warehouse operations. In this case, make a list of warehouse technologies that can streamline and automate your operations, such as:

- Automated Picking Tools. There are several automated picking tools on the market that can significantly boost the accuracy of a warehouse’s picking rates. Whether you choose robotic tools, voice-controlled order picking, or pick-to-light tools, you’ll need to consider how these tools navigate your warehouse and fit into your layout.

- Automated Guiding Vehicles (AGVs). Automated guiding vehicles can transport heavy goods and streamline the flow of products through your warehouse. Since they typically travel along marked lines or wires on the floor, it’s important that they are incorporated into the overall warehouse layout design.

- Automated Inventory Management Systems. Using RFID tags, an automated inventory management system makes it easy to quickly count and track items without manually moving or opening packages. If you plan on incorporating this technology into your operations, it’ll help you maximize the square footage of your warehouse by limiting the amount of free space you need to move and shift packages for counting.

- Warehouse Management System. If you don’t already have one, it’s essential that you incorporate a WMS into your warehouse. Today, a WMS is a critical component of an efficient warehouse. Data from all of your technology is gathered in one place, enabling you to visualize and understand how goods move through your warehouse space and how to most efficiently use your space. For example, you may design your warehouse layout one way now based on a fast-moving product. In a year’s time, that may change and your WMS will alert you to new trends in your inventory management, allowing you to adjust quickly and maximize efficiency.

- Collaborative Robots. These robots work with human employees to complete tasks. If you aren’t starting from scratch in your warehouse design, using collaborative robots can help you avoid drastically changing your layout while still benefiting from increased automation and efficiency.

- Automated Storage and Retrieval Systems (AS/RS). An AS/RS can fundamentally transform how your warehouse operates, effectively limiting the back and forth movement of workers. That said, they have a reputation for being clunky and are often recommended only for warehouses moving products with no interim activities that require manual intervention. If you intend to incorporate an AS/RS, remember that this will seriously impact your warehouse layout design planning.

Break up Your Project Tasks Into Key Milestones With Deadlines

Once you’ve identified the equipment you’ll need, your priority areas of improvement, and the project scope, create a detailed schedule that includes:

- A list of individual tasks (e.g., RFP for AGVs vendors written)

- A list of key milestones (e.g., AGV vendor selected)

- The estimated start date and end date of each task

- The estimated duration of each task

- Dependencies for each task (e.g., AGV can’t be implemented until RFP process for AGV vendor is complete)

- Accountable “owner” for each task, who is responsible for overseeing its completion

- Support team assigned to each task that is managed by an owner

- A project sponsor (e.g., an executive team member with authority) who is available for approvals and escalations

Even if you’re the one responsible for most of these tasks, document each activity. It’ll help keep you accountable and organized while you also tackle other day-to-day business activities.

While you could use a spreadsheet to create a GANTT chart and share it with project stakeholders, project management software provides an easy way to quickly create project schedules and assign tasks.

Execution Phase: Make Your Warehouse Design Plans a Reality

If you’re starting from scratch, executing on your warehouse redesign is simply a matter of planning to work and then working to plan.

If you have day-to-day business activities to handle, you’ll have to choose between a “big bang” approach, where you implement all the changes at once, or a phased approach in which you implement changes bit by bit.

Factors ranging from your vendor’s installation specifications (e.g., for an AGV) and the size of your warehouse to the storage conditions of your goods (e.g., refrigerated) and even the time of year (e.g., high demand) will impact the approach you take. While the specifics vary, best practices for any business change initiative include clearly communicating the reasons for and the benefits of change to your workers.

While your warehouse layout changes will likely result in an easier workload for employees, it’s still an infrastructure overhaul they must bear through, a new layout they’ll need to learn, and new equipment they’ll have to be educated on. Keeping your workers in the loop reduces employee dissatisfaction and turnover and can contribute to a smooth implementation process.

Closing Phase: Gather Feedback, Assess Lessons Learned, and Plan for Further Enhancements

At this point, your project is complete, but the work isn’t done.

First, consider what went well and what went wrong. Then document these lessons learned, share learnings with key stakeholders, and keep them accessible for future warehouse layout improvement projects.

At the beginning of the project you likely identified optimization activities that were out of scope for this project or unrealistic for your timeline. Perhaps at the budgeting stage you realized that it wasn’t feasible to purchase all of the desired technology. The closing stage is your opportunity to plan ahead and use lessons learned to augment your company’s organizational knowledge.

Optimize Your Warehouse Layout for Success

Optimizing your warehouse layout is a strategic move that can lead to increased efficiency, reduced costs, and ultimately, a more profitable business. By following the project phases, identifying challenges, leveraging data-driven insights, and embracing technology and automation, you can transform your warehouse into a well-organized and highly productive operation. But the journey doesn’t end here. Continuous improvement is key.

To take your warehouse operations to the next level, consider Logiwa WMS, the industry-leading Warehouse Management System that provides real-time visibility and streamlines every aspect of your warehouse management. Don’t wait – unlock the full potential of your warehouse with Logiwa WMS today. Schedule your personalized demo now!

Related Terms

How to choose between various warehouse business structures? What’s the difference between a flow-through and an incorporation strategy? You can find more in Logiwa Blog.

The average inventory formula with all necessary definitions is here in Logiwa Blog. To learn more about how to calculate your average inventory, keep reading our article!

Understanding Beginning Inventory (opening stock) is key to managing high-volume fulfillment. In this article, you can find out how to calculate beginning inventory and how to use it to ensure uninterrupted fulfillment operations.

Popular among ecommerce retailers of all sizes and from countless industries, pre-orders are one of the most effective and versatile ways of selling products online today, therefore making the pre-order process an important part of ecommerce business for both small and big scale companies. Read more

The total cost formula is revealed in detail here in this blog post. Click now and learn more about how to calculate the total cost formula, and see the benefits.

Supplier Relationship Management

Supplier relationship management can help improve your supply chain operations and overall success through coordination and collaboration. Learn more in this guide.