Outshine traditional WMS with Logiwa’s AI-powered Fulfillment Management System (FMS).

Grow your 3PL, DTC, and B2B operations with our Cloud native Fulfillment Management System (FMS) designed for high-volume logistics.

Fast, Accurate Fulfillment is What We Do

During peak season Logiwa WMS customers experienced:

<20 Hour Lead Times

“Logiwa’s AI fulfillment optimization cut our number of hours needed to complete tasks by almost 60% .”

– Jannis Dargel, COO & Co-founder at Locad

“Logiwa really listened to our needs, and Logiwa IO is proof that they understand what we need to not only succeed, but to thrive.”

–Jim Heinecke, Systems Integration and Implementation at Flexport

Fulfillment Excellence is the New Competitive Advantage

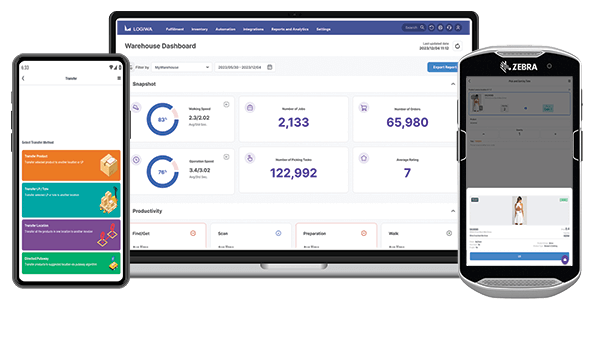

Deliver exceptional results with every order. Logiwa WMS is an AI-powered fulfillment platform that streamlines omnichannel logistics in one intuitive system.

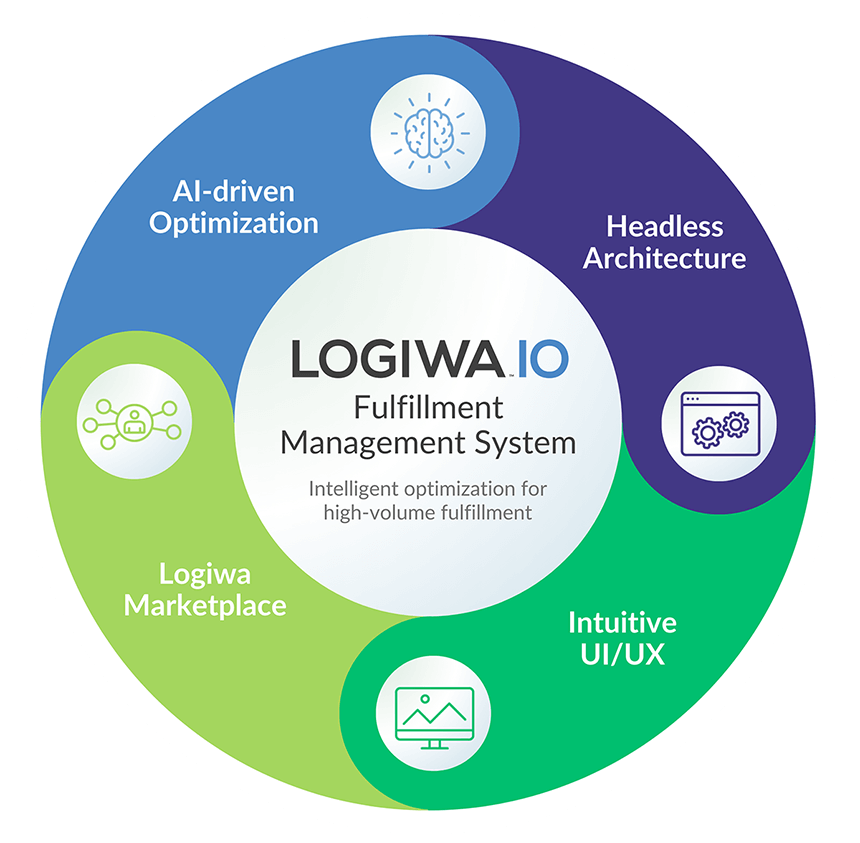

The Leading Fulfillment Management System

When it comes to meeting modern demand, traditional warehouse management systems can’t keep up. Logiwa’s all-in-one FMS offers an agile, scalable solution to meet your changing business needs.

Time to Value is our Superpower

Deploy in weeks not months. Train employees in less than a day. And cut lead times to hours. You’ll reach peak efficiency in no time.

Whether you are adding employees, new clients, or warehouses, Logiwa’s smart automation rules, flexible integrations and user-friendly application ensure success at every stage of growth.

Ecommerce, Shipping, Accounting and Robotics Partners Connect With Logiwa

More Than Just Great Software, We’re a High-volume Fulfillment Success Company

As a true SaaS product, Logiwa WMS continually adds new features and innovations to drive your business forward. We solve your most pressing fulfillment challenges and help you meet the toughest industry standards.

Implemented in weeks, not months

Logiwa is a true Cloud system that is easy to deploy, configure, and update as your business scales.

Optimized using AI and automation

Our pre-built automation rules and AI powered jobs speed up everything from your inbound operations to your picking, packing and shipping processes.

Supported every step of the way

Our customers rave about our customer support and we pride ourselves in our 7-9 minutes response time. We’re more than your software provider – we’re your partner for success.

Why Operations Choose Logiwa’s Fulfillment Management System

Logiwa’s software solution is designed to streamline the order fulfillment process for fulfillment networks, online retailers, 3PLs, brands, and wholesalers.

Our comprehensive suite of features encompasses order routing, warehouse management, inventory management, label printing, and billing. Logiwa offers a complete solution that enhances speed, accuracy, and customer satisfaction across the board.

Growth tips: Logiwa’s resources help you optimize your high volume fulfillment operations.

Driving Impactful Peak Season Results

Learn how leading DTC operations are thriving under peak season preassure.

Ask Our Experts: Get Answers to Your WMS Questions

Listen on demand for ways to increase the efficiency of your fulfillment operations.

State of Fulfillment Playbook

Discover ways to manage change and ensure ROI, speed and agility in a changing DTC world.