Optimize your operations to maximize productivity

Logiwa is warehouse management software done right. Our WMS helps brands, online sellers and 3PLs achieve high-volume order success.

Why Choose Logiwa WMS as Your Warehouse Inventory Management Software?

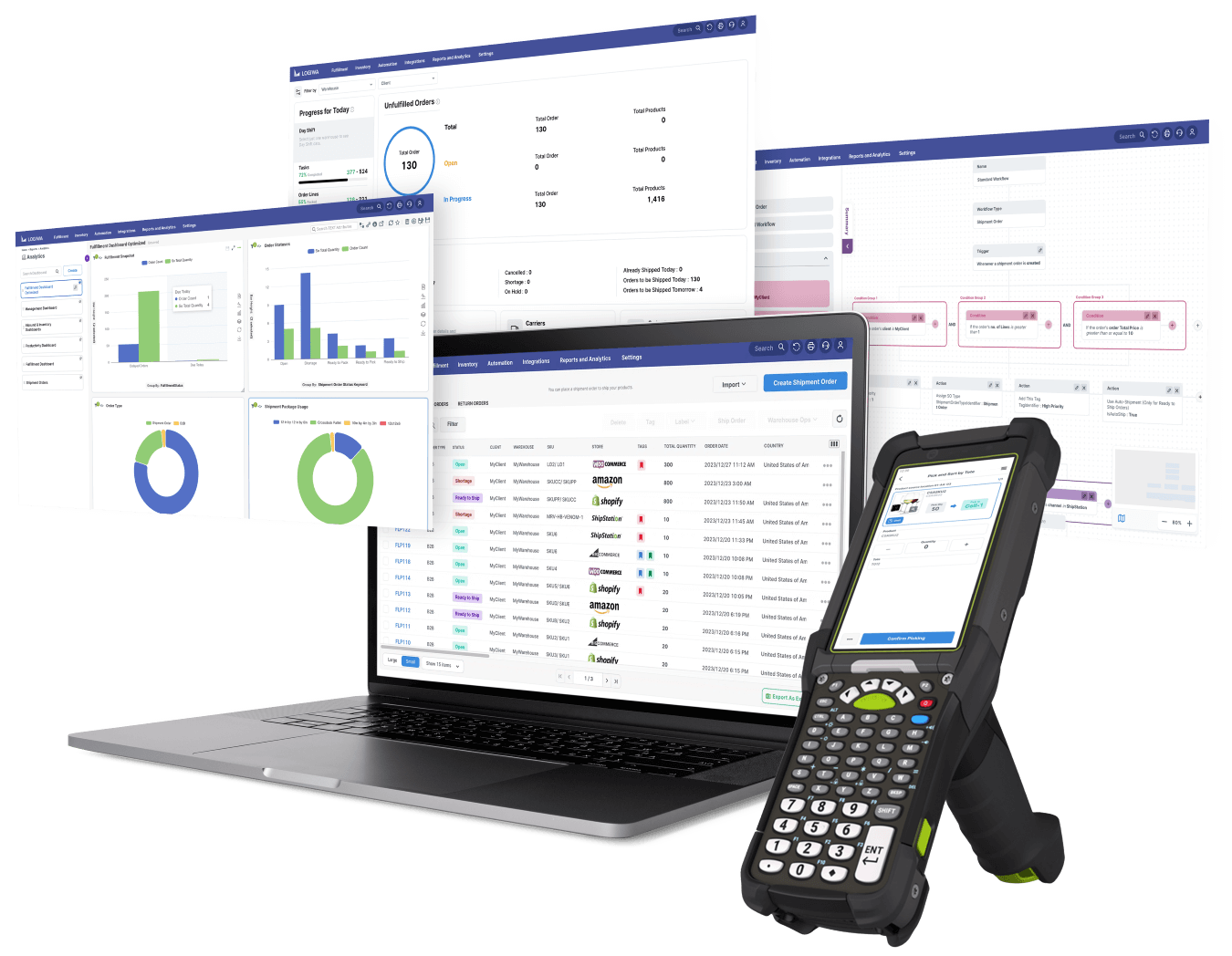

Logiwa WMS allows you to run a fully digital warehouse. Our cloud-based warehouse inventory management system offers a wide array of benefits and features at your fingertips – including mobile apps, smart job batching, automation rules, real-time exception handling, and online reports. Our forward-thinking approach to order fulfillment and industry-leading customer support has made us the number one choice for today’s competitive warehouse operations.

Let us show you Logiwa IO

The benefits of Logiwa’s warehouse management software

Improved Inventory Accuracy and Visibility

Real-time Tracking and Reporting

Streamlined Order Fulfillment Process

Enhanced Warehouse Efficiency and Productivity

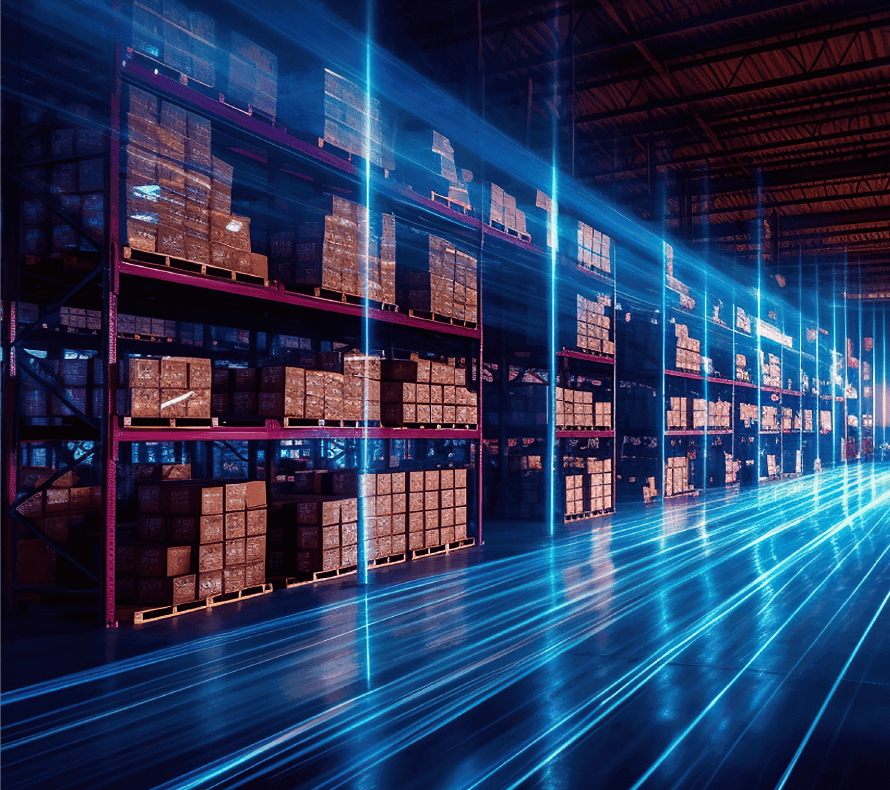

Logiwa’s Cloud Warehouse Management Software is Built Specifically for High-volume B2C and DTC businesses

The Logiwa Cloud Fulfillment Platform is a fully integrated order fulfillment system that empowers companies to run a digital fulfillment experience and grow direct-to-consumer business—without additional headcount.

The key features of Logiwa IO

Advanced inventory management for multi-warehouse operations

The control you need

Optimize multi-warehouse operations at both the macro and micro levels. Logiwa’s Warehouse Management System gives you the controls you need to:

- optimize inventory levels across fulfillment centers with location-based rules,

- perfect inventory management within each distribution center with

- group and zone-based rules,

- fixed and dynamic picking locations, and

- clear location capacities.

Get real-time visibility into inventory shortages at each warehouse, route orders to the best fulfillment center, and manage inventory transfers with ease.

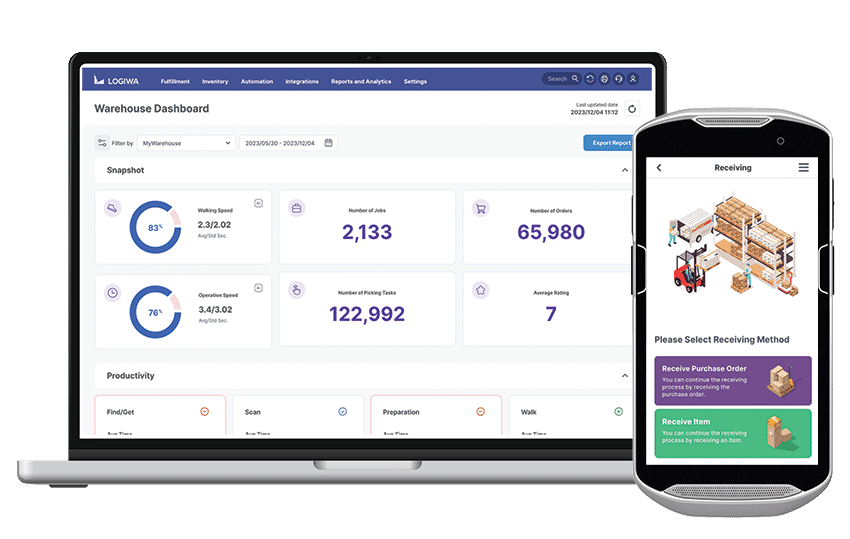

Mobile Order Tracking and Fulfillment

Real-time information on any device

Mobilize everything to understand how your employees move and operate in your distribution center. Mobile scanners send information about every item being received, put away, picked, packed, shipped, counted and transferred directly into Logiwa Cloud WMS System. Mobile reports let everyone see real-time inventory, order progress, and jobs from any mobile device.

Integration with Leading Ecommerce Platforms

Synced for optimized inventory

Sync your warehouse operations directly with the orders coming in through online channels such as Shopify, Magento, or Amazon. Keep inventory optimized during fluctuations in demand with real-time updates, and achieve 100% order accuracy with step-by-step mobile guidance as pickers pick, scan, report discrepancies, and adjust effortlessly as exceptions arise.

Barcode Scanning and Labeling

Streamlined processes

Simplify your warehouse processes with barcode scanning and labeling. Logiwa WMS supports barcode scanning for receiving, picking, packing, and shipping, eliminating manual errors and improving overall efficiency.

Customer Success

See what our customers say

More than just great software

We’re a high-volume Fulfillment Success Company.

As a true SaaS product, Logiwa WMS continually adds new features and innovations to drive your business forward. We solve your most pressing fulfillment challenges and help you meet the toughest industry standards.

Implemented in weeks,

not months

Logiwa IO is a true Cloud system that is easy to deploy, configure, and update as your business scales.

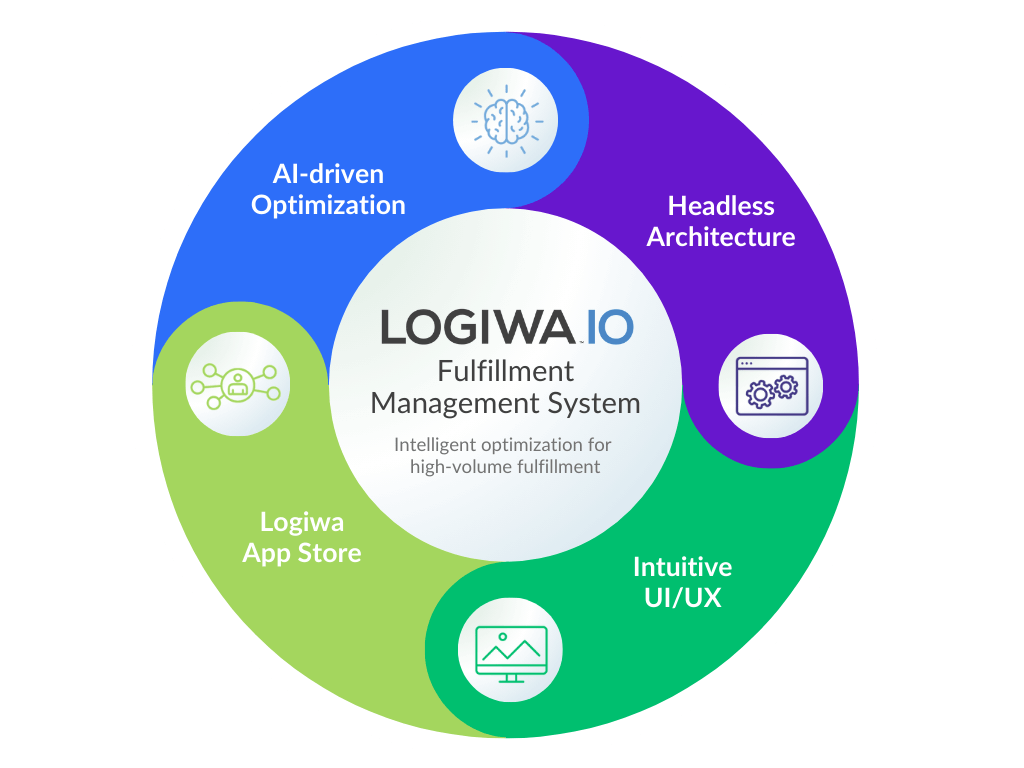

Optimized using AI

and automation

Our pre-built automation rules and AI powered jobs speed up everything from your inbound operations to your picking, packing and shipping processes.

Supported every step of

the way

Our customers rave about our customer support and we pride ourselves in our 7-9 minutes response time. We’re more than your software provider – we’re your partner for success.

Implemented in weeks, not months

Logiwa IO is a true Cloud system that is easy to deploy, configure, and update as your business scales.

Optimized using AI and automation

Our pre-built automation rules and AI powered jobs speed up everything from your inbound operations to your picking, packing and shipping processes.

Supported every step of the way

Our customers rave about our customer support and we pride ourselves in our 7-9 minutes response time. We’re more than your software provider – we’re your partner for success.

Pre-integrated with the leading ecommerce, marketplace, shipping, robotics, and accounting platforms.

Our areas of expertise

Logiwa’s warehouse inventory management system has everything brands and online sellers need to achive high-volume order fulfillment success

Warehouse

Operations

Warehouse

Productivity

Warehouse

Optimization

FAQs about warehouse management software

What is a warehouse management system (WMS)?

A WMS solution from Logiwa can help to improve the efficiency and accuracy of warehouse operations, leading to reduced costs and increased productivity. Logiwa WMS can also help to reduce the risk of errors, such as lost or damaged goods, and improve customer satisfaction by enabling faster and more accurate order fulfillment.

How is a WMS different from an enterprise resource planning (ERP) system?

An ERP system is a broader type of business management software that includes a range of modules for managing different aspects of your business, such as accounting, HR, and supply chain management. A WMS is focused specifically on managing warehouse operations and is typically integrated with an ERP system as one of its modules.

How is Logiwa WMS implemented in my warehouse?

Implementing Logiwa WMS involves four distinct phases to address the unique needs of your operation, such as its size and complex fulfillment processes. Our highly effective approach includes business process & change analysis, configurations testing, training & practices, a dry run, assisted go-live care, and follow-up support for a positive post-onboarding experience. We utilize project management tools, so that it is clear who is responsible for what tasks to keep the project on track and even, whenever possible, complete your first order with you.

How does Logiwa WMS work?

Logiwa WMS consists of a central database that stores information about the warehouse and its operations, as well as a user interface that allows warehouse staff to access and update this information and 3PL operations can provide clients with custom portals. The system may also include mobile devices, such as handheld scanners, that allow warehouse staff to track and manage inventory in real-time.

Can Logiwa WMS be customized to meet the specific needs of my business?

Yes, Logiwa WMS is highly configurable and can be tailored to meet the specific needs of your business. This can include customizing the user interface, integrating with other business systems, and adding or modifying fulfillment features to meet your specific requirements.

How does Logiwa WMS benefit my business?

A WMS solution from Logiwa can help to improve the efficiency and accuracy of warehouse operations, leading to reduced costs and increased productivity. Logiwa WMS can also help to reduce the risk of errors, such as lost or damaged goods, and improve customer satisfaction by enabling faster and more accurate order fulfillment.