In the high-stakes world of warehousing and fulfillment, AI job optimization is a game-changer. This method uses AI to strategically improve picking and packing, boost labor productivity, reduce expenses, and enhance order fulfillment.

- AI Jobs typically visit 40% fewer locations when combining Picking & Packing to optimize.

- Logiwa users have realized up to 58% efficiency gain and labor cost reduction with AI-driven jobs.

By integrating ecommerce orders, inventory data, and smart automation, warehouse AI is setting new benchmarks in high-efficiency fulfillment. Offering more precise and personalized approaches to meeting customer needs, AI is transforming the customer experience.

Contents

Key Takeaways

- Combining AI and automation ensures operations are able to meet the complex and dynamic needs of modern ecommerce.

- AI in the warehouse uses operational data (e.g. orders, stock levels, shipping details, stock location, etc.) to align orders with optimized picking and packing processes.

- AI job optimizations result in high-efficiency pick lists, optimized job waves, continuous operations, and adaptive learning.

- Warehouse AI leads to increased throughput, minimal manual intervention, higher labor efficiency, cost-savings, and high-efficiency fulfillment results.

The Necessity of AI and Automation for Fulfillment

The next era of fulfillment management involves using the power of warehouse AI. Combining AI and automation ensures your operation is able to meet the dynamic needs of ecommerce. That includes being able to react at a moment’s notice.

AI solves complex logistics problems to ensure high-efficiency workflows, reduced waste, and improved order processing. It aids smart order routing, shipping rules, and directed putaway, as well as picking and packing.

This helps you increase labor efficiency, throughput, and customer satisfaction with faster, more accurate order deliveries.

Understanding AI Job Optimization

AI-driven job optimization minimizes the total number of locations and times warehouse employees have to visit locations. It ensures that picking and packing operations always complete high priority orders first.

AI examines orders, SKU quantities and sizes, storage rules, inventory spots, and picking routes to categorize orders.

This results in:

- High-Efficiency Picking: Supporting methods like batch picking, which reduce the time and effort in fulfilling orders.

- Optimized Job Waves: Utilizing batch picking or tote-based workflows, such as single item batch pick, identical order batch pick, and multi-item cluster pick jobs.

- Continuous Operations: Integrating new orders, inventory level changes, and shipment schedules in real-time to maintain a steady operational flow.

- Adaptive Learning: AI systems learn and adapt to changing patterns, continually refining the fulfillment process.

AI can generate company, user, item, and warehouse-specific standards to generate dynamic, operation-centric solutions. That means that AI provides unique solutions specific to the needs of individual operations.

AI in the warehouse ushers in a new era of fulfillment excellence that helps businesses reach new levels of success.

Benefits of AI Job Optimization for High-Volume Fulfillment Operations

With smart job creation and picking features, your fulfillment network is able to shorten shipping lead time and achieve competitive shipping like same-day and next-day shipping with greater ease. It ensures you are able to adapt effectively to changing conditions while maintaining fulfillment excellence.

In comparative trials against manually created job waves, Logiwa IO’s AI Driven Job Optimization has demonstrated remarkable results: Logiwa users have seen up to 58% efficiency gain over manual operations.

Operational Benefits of AI Job Optimization:

- Increased Throughput: AI algorithms analyze and predict order patterns, ensuring warehouses are always a step ahead.

- Elimination of Manual Tasks: Automation of repetitive tasks reduces human error and frees up labor for more critical tasks.

- Labor Efficiency: AI-driven tools assist in workforce management, optimizing staff deployment based on real-time demands.

- Cost-Savings: With better inventory management and streamlined processes, AI significantly cuts down operational costs.

- High-Efficiency Fulfillment Results: Enhanced coordination between various stages of fulfillment leads to faster and more accurate deliveries.

- Supply Chain Sustainability: Increased operational efficiency lowers carbon emissions by reducing energy use and increasing the number of orders in each shipment.

Industry Benefits of Warehouse AI

Adopting AI as part of your day-to-day operations shows customers and competitors that you are a forward-thinking company. It can also impact the satisfaction of your employees, as it eases their workloads and provides the opportunity to learn a new invaluable skill.

The rise of AI in the warehouse increases the importance of AI-based skills and training in the labor market. Your company gains a competitive advantage by teaching employees to use AI technologies. This gives workers the ability to interact with AI-based systems and contribute to their career development.

Unlock a personalized tour of Logiwa IO

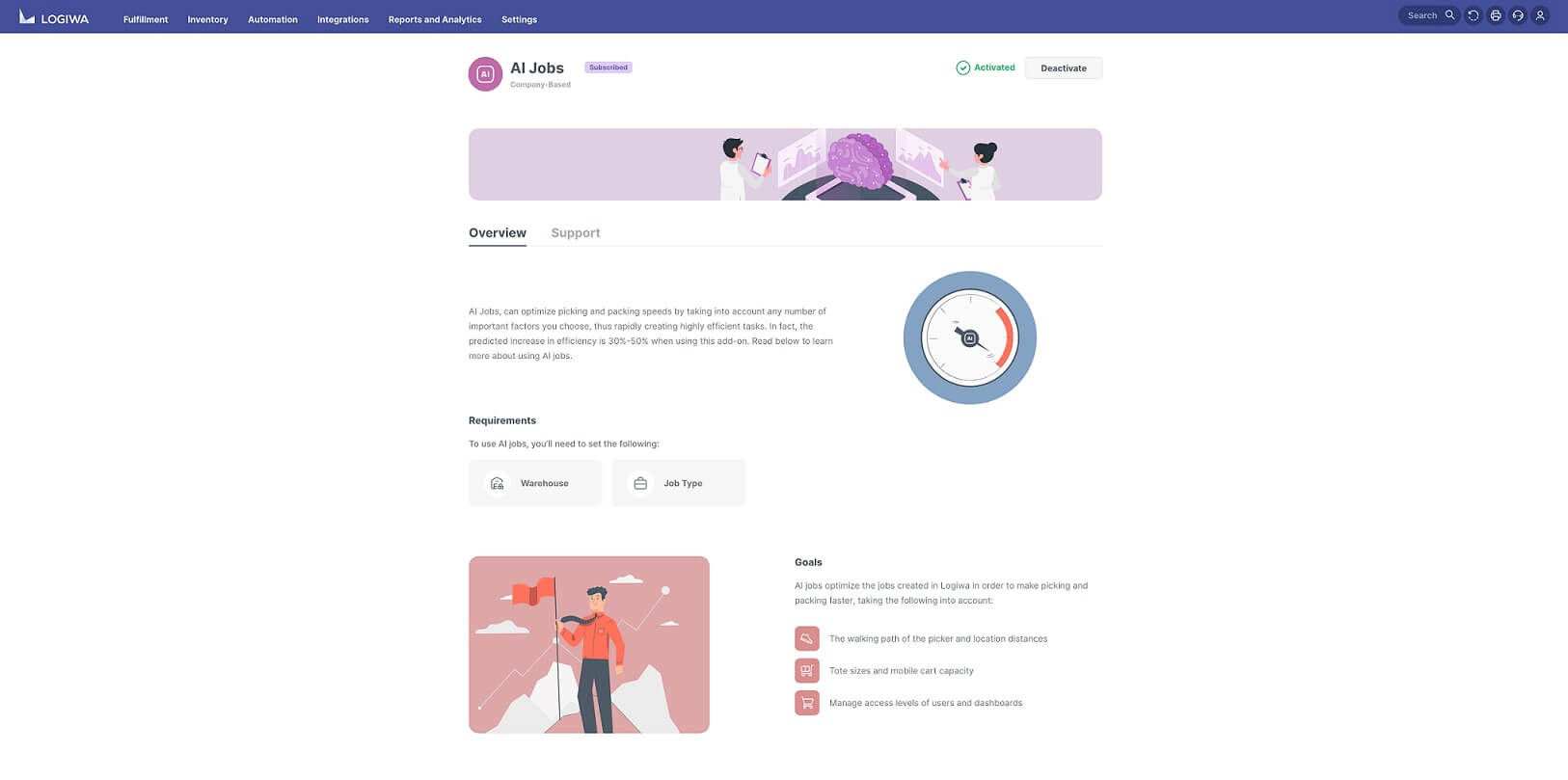

How Logiwa’s AI Job Optimization Works

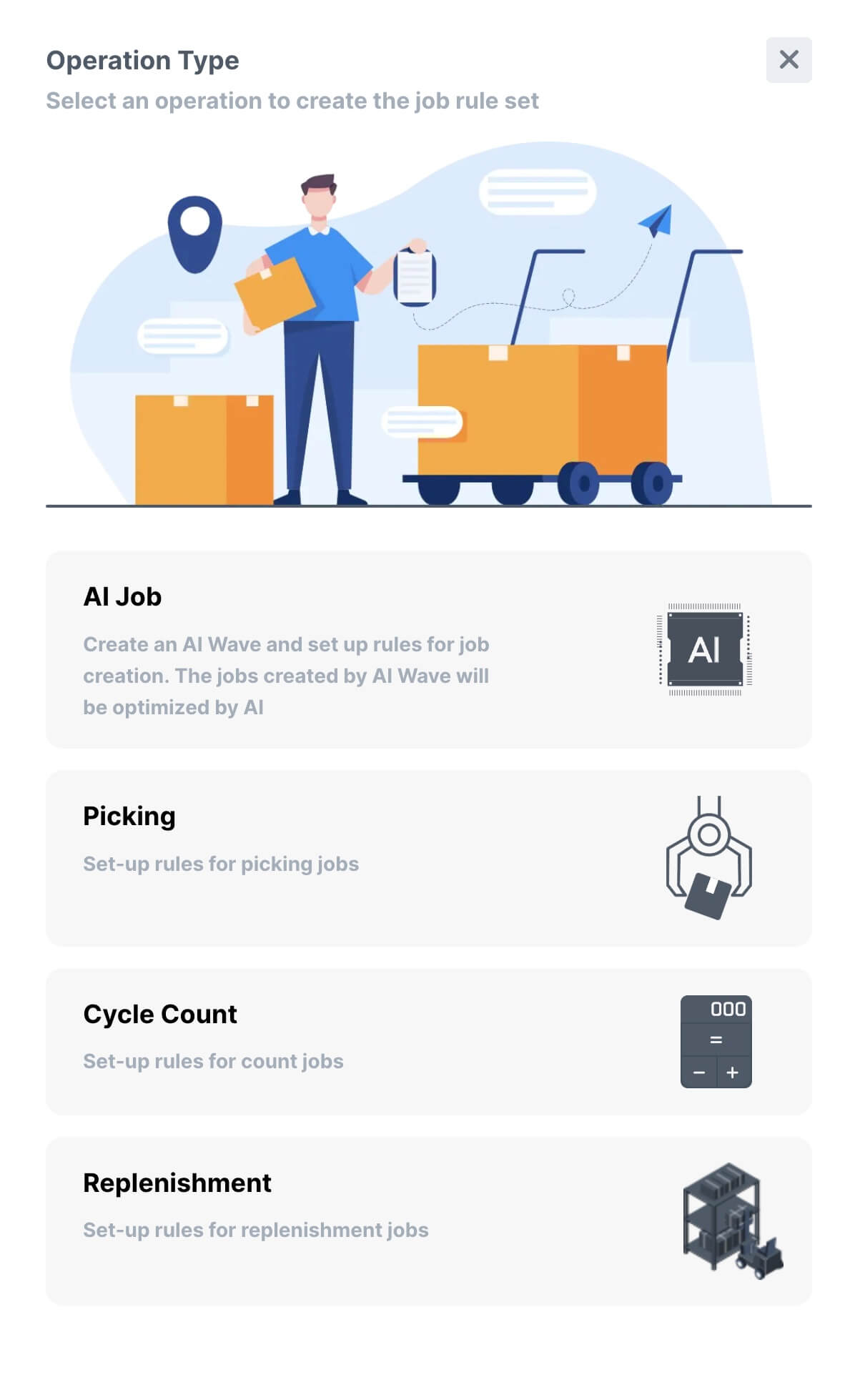

In Logiwa IO, AI-driven jobs start with smart job creation and picking wave automation. Out Cloud-native Fulfillment Management System (FMS) makes it easy to build out custom automation rules.

Our AI Engine checks several things to ensure jobs are as efficient as possible:

- Picking Location Distances: groups tasks with closer locations together

- Order Volumes/Dimensions: compares and plans based on product, tote, and cart sizes

- Job Type Batch sizes

Based on the results, Optimized Jobs and Tasks for the Wave are created and pushed back into Logiwa IO to continue streamlining your operations. This means it can design the jobs based on physical operational requirements (e.g. bulk label printing, certain picking strategies, the totes and carts being used, etc.).

AI can understand the need and compare multiple possibilities and decisions to decide on the best course of action. Unlike rule based flows, AI can emulate human decision-making.

Here’s an example:

You have multi-line jobs and single-line jobs as part of your warehouse operations. For multi-line jobs, you use a cluster picking approach. Depending on available capacity, you may be able to add single item orders to those flows to improve overall efficiency.

However, you cannot add multi-line orders to single-line jobs. If the total cost of this decision is lower than the total separation, AI can understand it and combine single item orders into multi-line jobs as is appropriate.

Get Started with Warehouse AI

Ready to optimize your warehouse operations features like AI job optimization? Logiwa is leading the way with our future-ready solution. Discover the different types of AI available to your operations in our guide, “Critical Role of AI in Warehouse Operations.”

For more insights into Logiwa’s cutting-edge Fulfillment Management System (FMS), set up a free discovery call with one of our industry experts.

FAQs Related to AI Job Optimization

Is it difficult to implement warehouse AI for the first time?

AI for warehouse management is new to the industry, but that does mean it is difficult to implement with the right team. Logiwa provides the experience and technical skills required to manage this type of advanced software on your behalf. Our AI is easy to turn on and use because it addresses potential complications with dependable design.

What is AI job optimization in warehousing and fulfillment centers?

AI-driven job optimization minimizes the total number of locations and times warehouse employees have to visit locations. It ensures that picking and packing operations always complete high priority orders first.

How does warehouse AI impact workforce requirements and labor efficiency?

AI for warehouse management streamlines day-to-day tasks for increased efficiency. This makes tasks like order picking faster and maximizes throughput while minimizing the need for additional headcount. With the addition of autonomous mobile robots (AMRs), workers can accomplish even more.

Does AI job optimization use or benefit from other system integrations?

Logiwa’s AI engine is part of Logiwa’s Fulfillment Management System (FMS). It therefore has access to all critical operational data flowing in our highly integrated platform. This includes ecommerce platforms, online markets, shipping carriers, and more.

How does artificial intelligence (AI) handle sudden changes in order volume?

AI tools are adept at quickly adapting to changes. AI solutions ensure seamless operations regardless of order volume fluctuations by using real time data to inform warehouse automation. Moreover, machine learning algorithms can help with data driven forecasting to prepare operations for fluctuations.

Fulfill Brilliantly with Logiwa IO: Meeting Modern Fulfillment Challenges Head-On.

Warehouse Management

Modern digital WMS powers a modern fulfillment experience