Wholesale

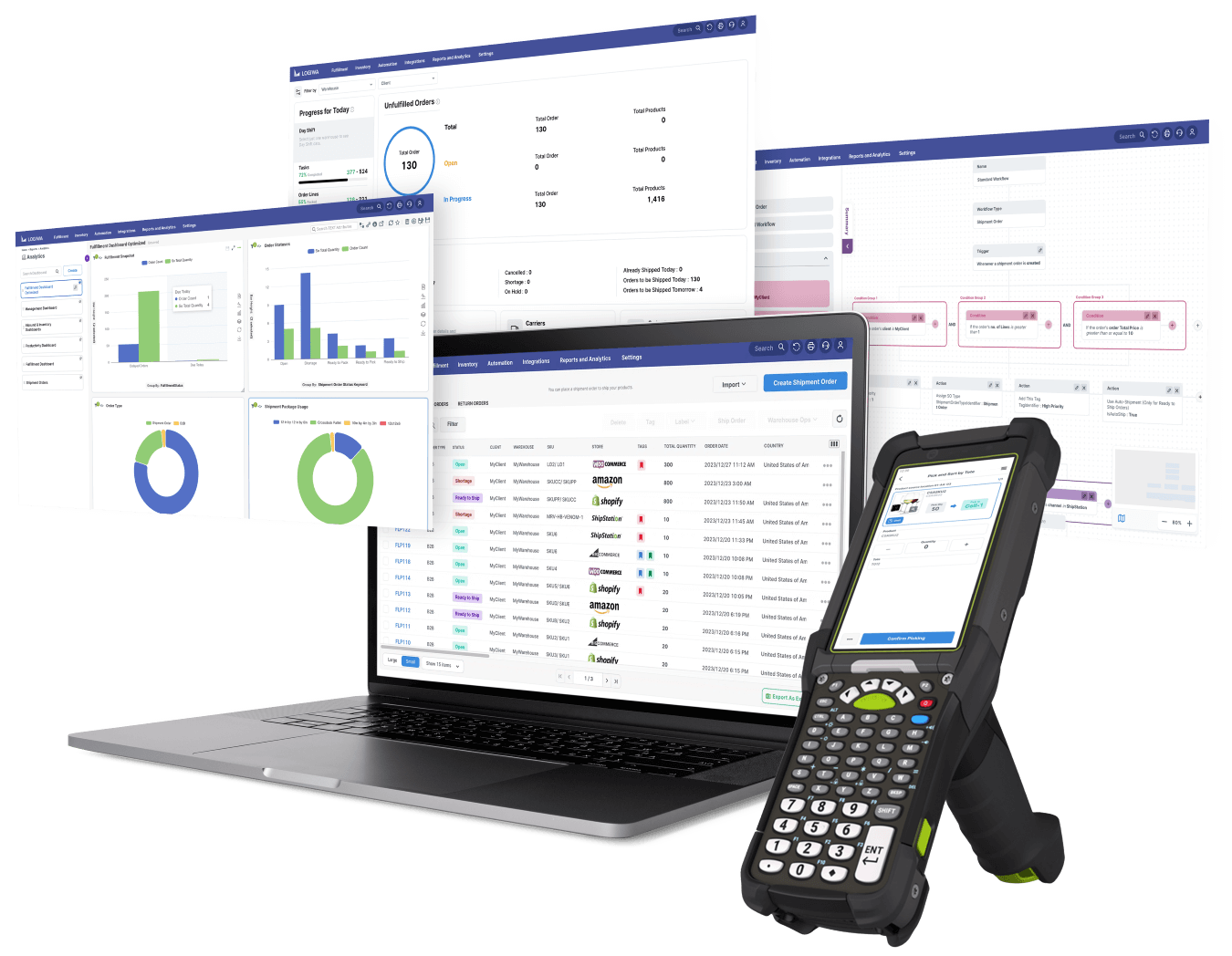

Highly integrated, agile wholesale warehouse management software

improved

efficiency

10x

more orders

shipped

Challenges

The best warehouse management software (WMS) to meet your wholesale distribution needs

Wholesale distribution has many challenges like managing stock, keeping up with demand, and tracking orders. The right wholesale fulfillment software can make these tasks easier by automating inventory tracking, improving order accuracy, and helping you stay on top of operations. Logiwa features real-time tracking, easy-to-use inventory tools, and smooth integration with your current systems to help your business run more smoothly as you scale.

Logiwa IO can help.

Schedule a call.

Solutions

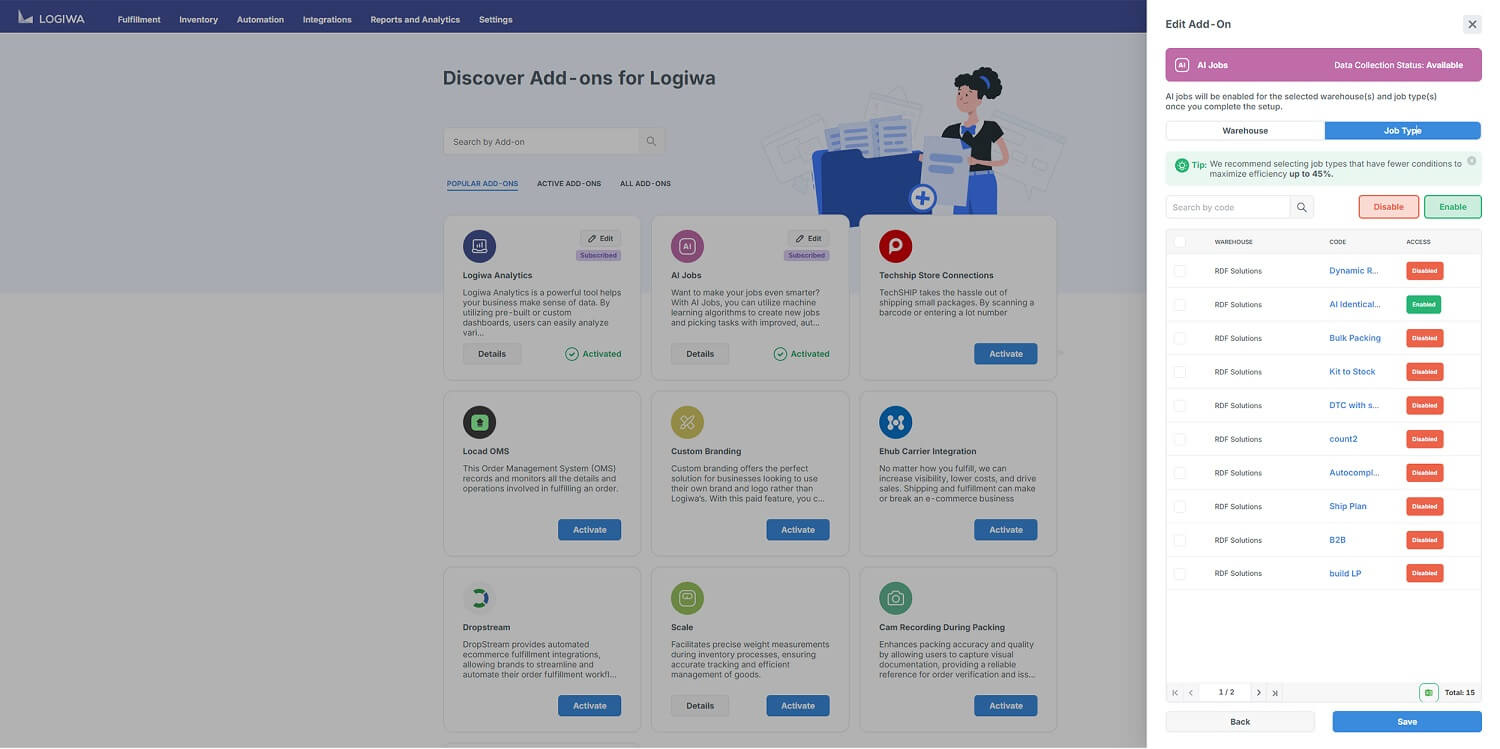

Logiwa IO helps wholesalers and distributors conquer hybrid B2B and DTC fulfillment operations

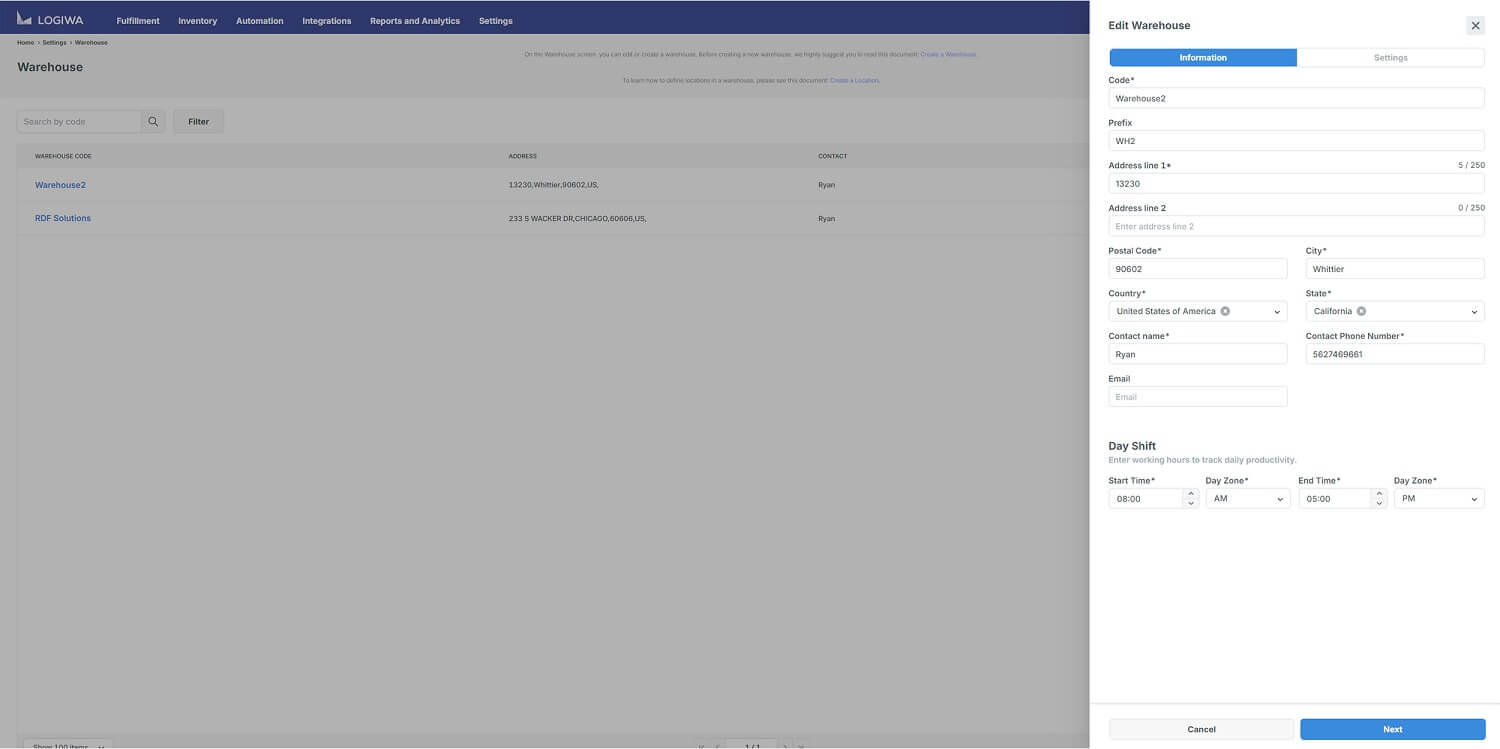

With Logiwa’s cloud-based warehouse management software, you can easily manage inventory, omni-channel orders, and customer relationships. Our solution simplifies supply chain logistics, improves inventory control, and ensures fast, accurate wholesale fulfillment for retailers, suppliers, and DTC operations.

Track key aspects of your business with the flexibility to scale effortlessly. No matter how your business grows, Logiwa’s smart automation and integrations give you the tools to succeed without slowing down.

Activate your workforce faster

Logiwa IO’s modern user interface is unmatched in the industry. Easy to use, intuitive screens allow 3PLs to onboard employees faster with minimal need for training. Quickly bring temporary hires up to speed during high-volume peak seasons and cross train employees easily.

Designed with flexibility in mind

Logiwa IO is built on a headless architecture. This means every action you take on our user interfaces has a matching endpoint (web service) that you can use to design and implement your own experiences beyond Logiwa IO.

Take control of complex inventory and shipping

Ensure accuracy and improve efficiency by building full pallets for specific client needs directly during the picking process. And streamline shipping with Logiwa IO’s shipment plan, a powerful tool that efficiently manages orders while offering real-time visibility. Simplify creating custom shipment plans and manage multiple orders seamlessly, ensuring a smooth and tailored wholesale shipping process

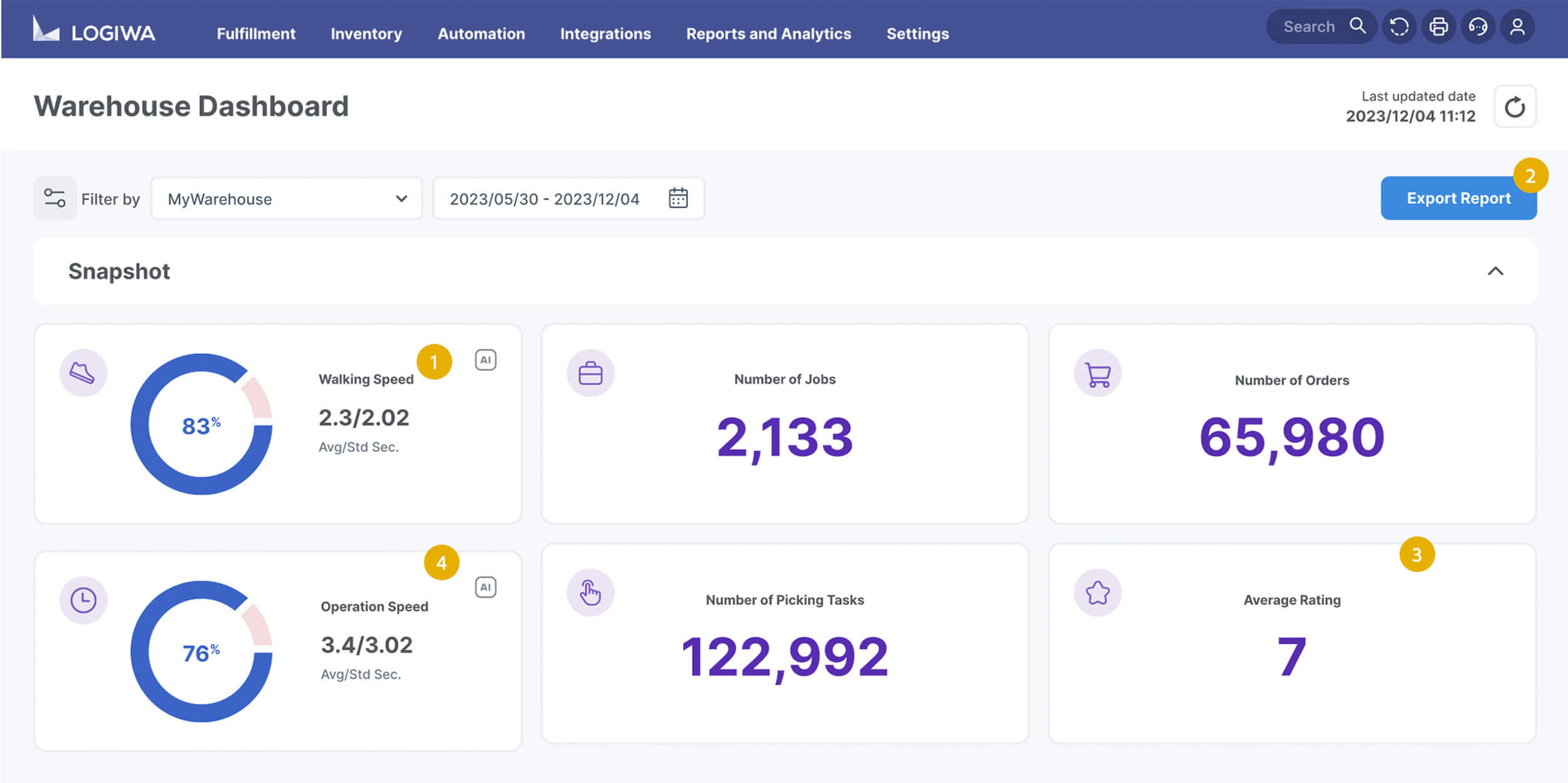

Your best warehouse manager

Logiwa IO’s AI-driven wholesale warehouse management software continuously tracks order flow and available resources then automatically creates optimized jobs for your workforce. It’s like having 10 of your best warehouse managers working together 24/7.

Every step counts

Items picked per hour is only a small part of the story. Logiwa IO’s Labor Tracking and Reporting solutions continuously track all physical and digital activities completed via desktop and mobile applications. This unmatched visibility over your wholesale warehouse operations allows you to continuously identify opportunities for improvement.

Scalable volume-based pricing

Logiwa felt wholesale WMS pricing models begged reassessment. How is it in your WMS provider’s interest to aim for efficiency when their revenue is dependent on the number of user licenses they sell you? That’s why Logiwa IO uses a volume-based pricing model. It aligns your goals with ours. It’s a win-win and another way we help wholesalers fulfill brilliantly.

Customer Success

See what our customers say