Online Sellers

Online Sellers Excel with Logiwa’s Real-time Ecommerce Inventory Management Software

Achieve Fast, Accurate Fulfillment with Logiwa’s Ecommerce Inventory Management Software

When it comes to mastering high-volume fulfillment, inventory management is key to overcoming fluctuating demand, selling more, and ensuring long-term profitability for online sellers, retailers, and 3PLs. Logiwa’s cloud fulfillment platform was built with the complexities of modern ecommerce in mind—and our approach to smart inventory management can’t be beat.

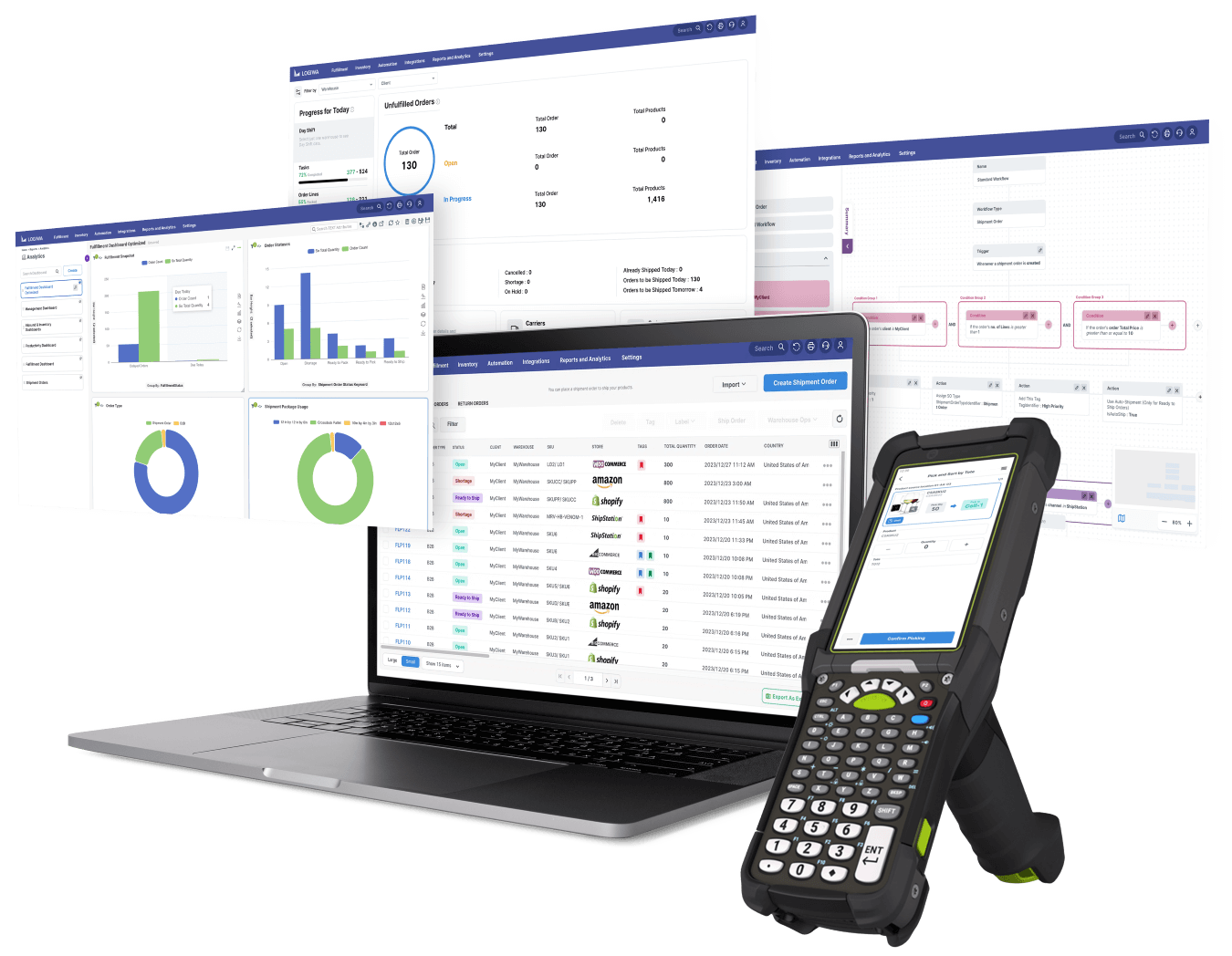

Logiwa WMS provides real-time visibility and control over your inventory. Our solution integrates the online order data from your ecommerce channels with your warehouse operations to optimize stock levels, route orders to the best fulfillment centers, and streamline competitive workflows. Say goodbye to costly stockouts and shortages, and hello to high-efficiency inventory management all year long.

Let us show you Logiwa IO

Inventory Management Software for Fulfillment Excellence

Real-Time Inventory Visibility and Control

Storage Optimization

Smart Automation

Take advantage of Logiwa’s intelligent warehouse automation features to streamline your operations. From receiving and putaway to automated replenishment, our system optimizes your workflows and minimizes manual errors. Route orders based on item availability and proximity to your consumers. Create pick lists that prioritize expiration dates and minimizing deadstock. Choose shipping boxes based on the dimensions of your inventory and multi-item orders. All in the name of optimized inventory managemen

Stock Reporting and Demand Forecasting

Customer Success

See what our customers say

Logiwa’s Inventory Management Software

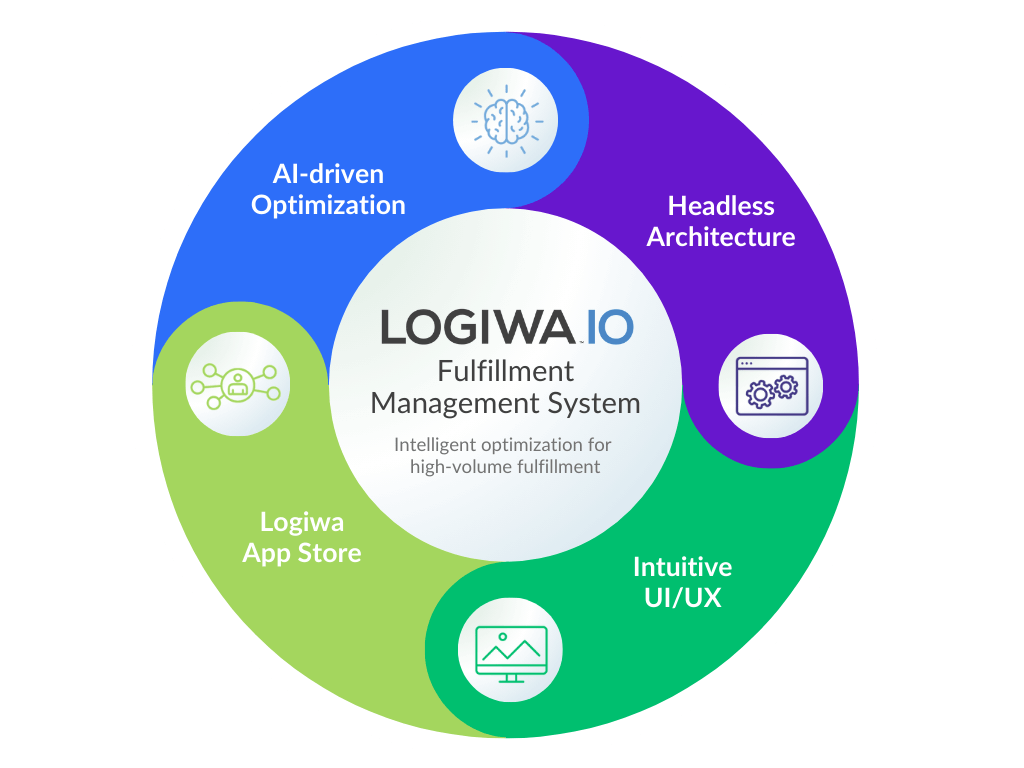

The Logiwa Cloud Fulfillment Platform is a fully integrated Warehouse Management System and order fulfillment system that empowers companies to run a digital fulfillment experience and grow your direct-to-consumer business—without additional headcount.

AI-driven Optimization

Streamline operations with waves and jobs for enhanced outbound flow. Monitor on-ground activities to optimize workforce management with labor standards.

Headless Architecture

Groundbreaking headless, versionless, and serverless architecture. Seamlessly adapt your operations to changing needs, design your own add-ons, and scale effortlessly.

Intuitive UI/UX

Ensures an engaging user experience with an intuitive app design. Onboard new employees in hours, not days.

Logiwa Marketplace

Our partner ecosystem allows you to add features and modules—your own, and those from the marketplace—for limitless configurability and continuous innovation.

Logiwa’s Ecommerce Inventory Management Software has Everything 3PLs Need to Achieve High-volume Order Fulfillment Success

Imagine all this power running on your mobile devices in a fully digital warehouse that’s part of your integrated fulfillment network. That’s Logiwa inventory management software.

- Unlimited Locations/Bins

- Inventory and Locations Management

- Transfers Between Locations and Warehouses

- Instant Counting

- Purchase Order Management

- Inbound Receiving Management

- PO Notification Email Alerts

- Returns Management

- Safety Stock Reports and Email Alerts

- Shipping Management

- Pick, Pack and Ship Operations

- Backorders and Damaged Products

- Carrier Rate Shopping

- Shipment Tracking Number Management

- Lot/Batch, Expiry Date, and Serial Number Tracking

- Pick Face Replenishment

- Multi-warehouse operations

- Multi-client operations

- Shipment rule automation

- DTC packing station

- Kitting and bundling

- Scale integrations

- Order routing

- Putaway automation rules

- Inventory allocation automation rules

- Automate picking job creation

- Shipment box suggestions

- Walking path optimization

- Put-to-wall

- Robotics in

Logiwa’s Inventory Management Software Makes a Fast Impact on Your Business

More than just great software

We’re a high-volume Fulfillment Success Company.

As a true SaaS product, Logiwa WMS continually adds new features and innovations to drive your business forward. We solve your most pressing fulfillment challenges and help you meet the toughest industry standards.

Implemented in weeks,

not months

Logiwa IO is a true Cloud system that is easy to deploy, configure, and update as your business scales.

Optimized using AI

and automation

Our pre-built automation rules and AI powered jobs speed up everything from your inbound operations to your picking, packing and shipping processes.

Supported every step of

the way

Our customers rave about our customer support and we pride ourselves in our 7-9 minutes response time. We’re more than your software provider – we’re your partner for success.

Implemented in weeks, not months

Logiwa IO is a true Cloud system that is easy to deploy, configure, and update as your business scales.

Optimized using AI and automation

Our pre-built automation rules and AI powered jobs speed up everything from your inbound operations to your picking, packing and shipping processes.

Supported every step of the way

Our customers rave about our customer support and we pride ourselves in our 7-9 minutes response time. We’re more than your software provider – we’re your partner for success.

Pre-integrated with the leading ecommerce, marketplace, shipping, robotics, and accounting platforms.

FAQs about Ecommerce Inventory Management Software

What is Logiwa’s ecommerce inventory management software?

Logiwa’s inventory management software is used by online sellers to manage their inventory and order fulfillment processes. Logiwa helps to automate and streamline tasks like receiving, putaway, picking and packing operations, leading to cost savings and increased efficiency.

How is Logiwa’s ecommerce inventory management software implemented in my business?

Can Logiwa’s ecommerce inventory management software be customized to meet the specific needs of my business?

What types of tasks can Logiwa’s ecommerce inventory management software help to automate?

Nearly every warehouse task can be automated with Logiwa inventory management software, including material handling, order picking, packing, and sorting. Automation can also be used for tasks such as:

- Tracking inventory levels

- Processing orders

- Coordinating the movement of orders within the warehouse

- Generating reports and analytics

- Data entry processes that affect the success of your business

How do I choose the right ecommerce inventory management software for my business?

How does Logiwa’s ecommerce inventory management software benefit my business?