Powerful Fulfillment Software for Growing 3PL Networks

Achieve a Seamless Fulfillment System with Logiwa WMS

Logiwa WMS is built to help fulfillment networks and 3PLs scale and impress clients with an exceptional fulfillment experience. Our fulfillment network software:

- can be up and running in weeks at any number of warehouses,

- easily expand as you bring on new clients, and

- has simple pay-as-you-go monthly pricing.

Logiwa helps you stay nimble with a flexible order management system that can adapt and support your constantly evolving operations as you bring on new warehouses, new clients, and fulfill an ever-growing portfolio of products.

Let us show you Logiwa IO

Unleash the Power of Strong Order Fulfillment Software

Real-Time Inventory Visibility and Control

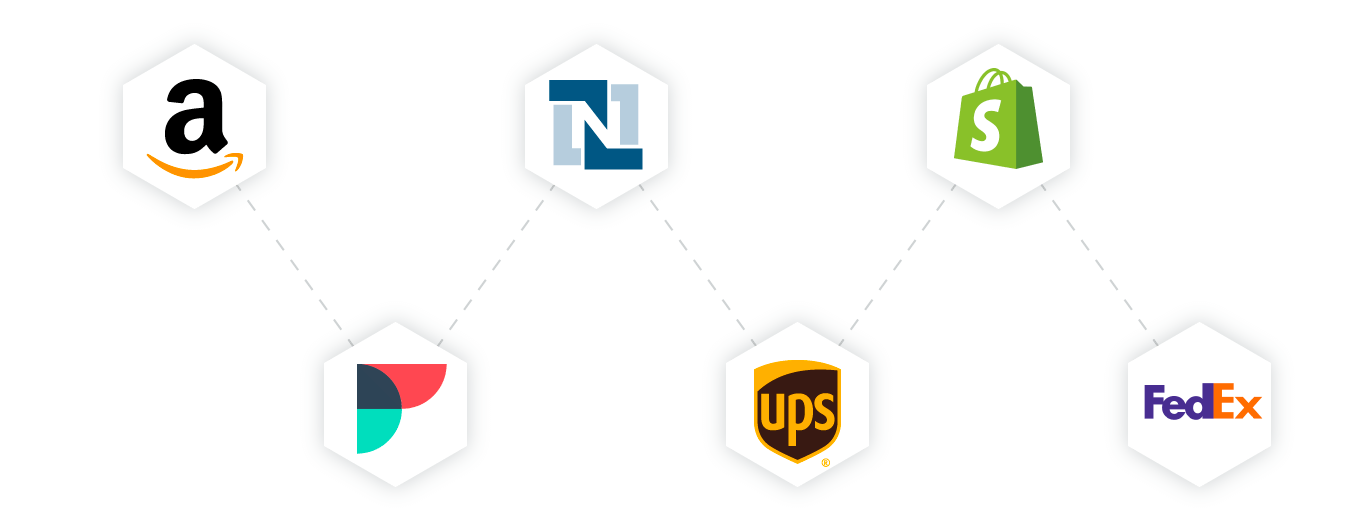

Seamless Integrations

Effortlessly connect Logiwa WMS to your preferred sales channels, marketplaces, and carriers with our Integration Orchestrator. Eliminate manual data entry, improve order accuracy, and simplify shipping processes to boost your fulfillment network’s efficiency.

Agile Order Management

Simplify your order processing with Logiwa’s agile order management system. Automate workflows, track orders in real time, and ensure accurate picking, packing, and shipping to meet the demands of your ecommerce customers.

Actionable Analytics and Reporting

Make informed decisions and drive continuous improvement with Logiwa’s robust analytics and reporting capabilities. Access comprehensive insights into your fulfillment network’s performance, identify bottlenecks, and optimize your operations for growth.

Intelligent Warehouse Automation

Customer Success

See what our customers say

Logiwa’s Warehouse Automation Software is part of our Cloud Fulfillment Platform.

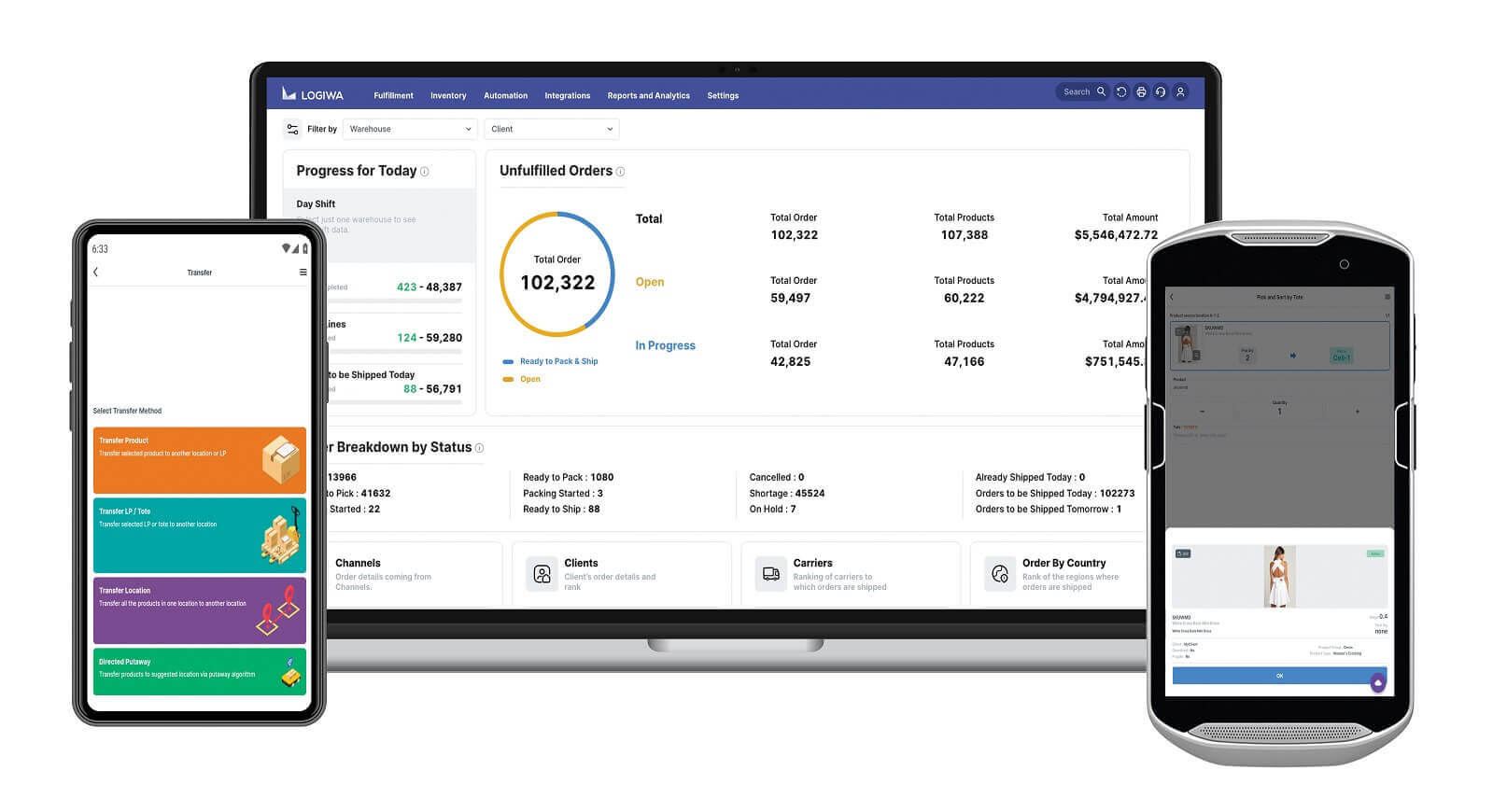

The Logiwa Cloud Fulfillment Platform is a fully integrated Warehouse Management System and order fulfillment system that empowers a digital fulfillment experience for maximizing direct-to-consumer growth—without additional headcount.

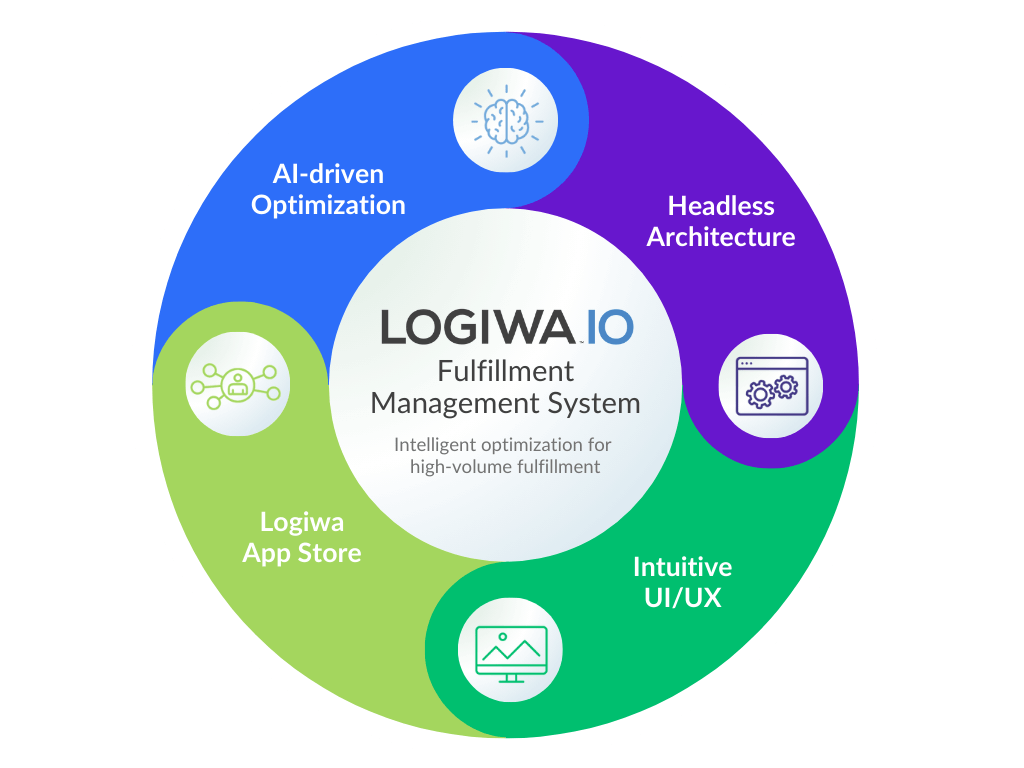

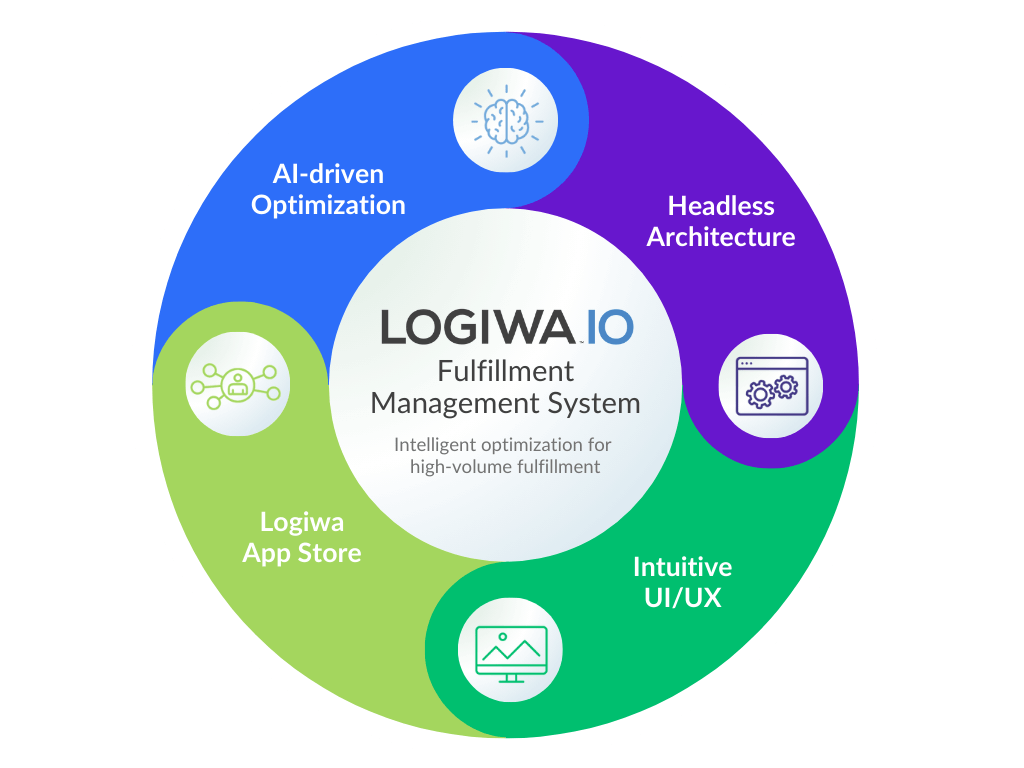

AI-driven Optimization

Streamline operations with waves and jobs for enhanced outbound flow. Monitor on-ground activities to optimize workforce management with labor standards.

Headless Architecture

Groundbreaking headless, versionless, and serverless architecture. Seamlessly adapt your operations to changing needs, design your own add-ons, and scale effortlessly.

Intuitive UI/UX

Ensures an engaging user experience with an intuitive app design. Onboard new employees in hours, not days.

Logiwa Marketplace

Our partner ecosystem allows you to add features and modules—your own, and those from the marketplace—for limitless configurability and continuous innovation.

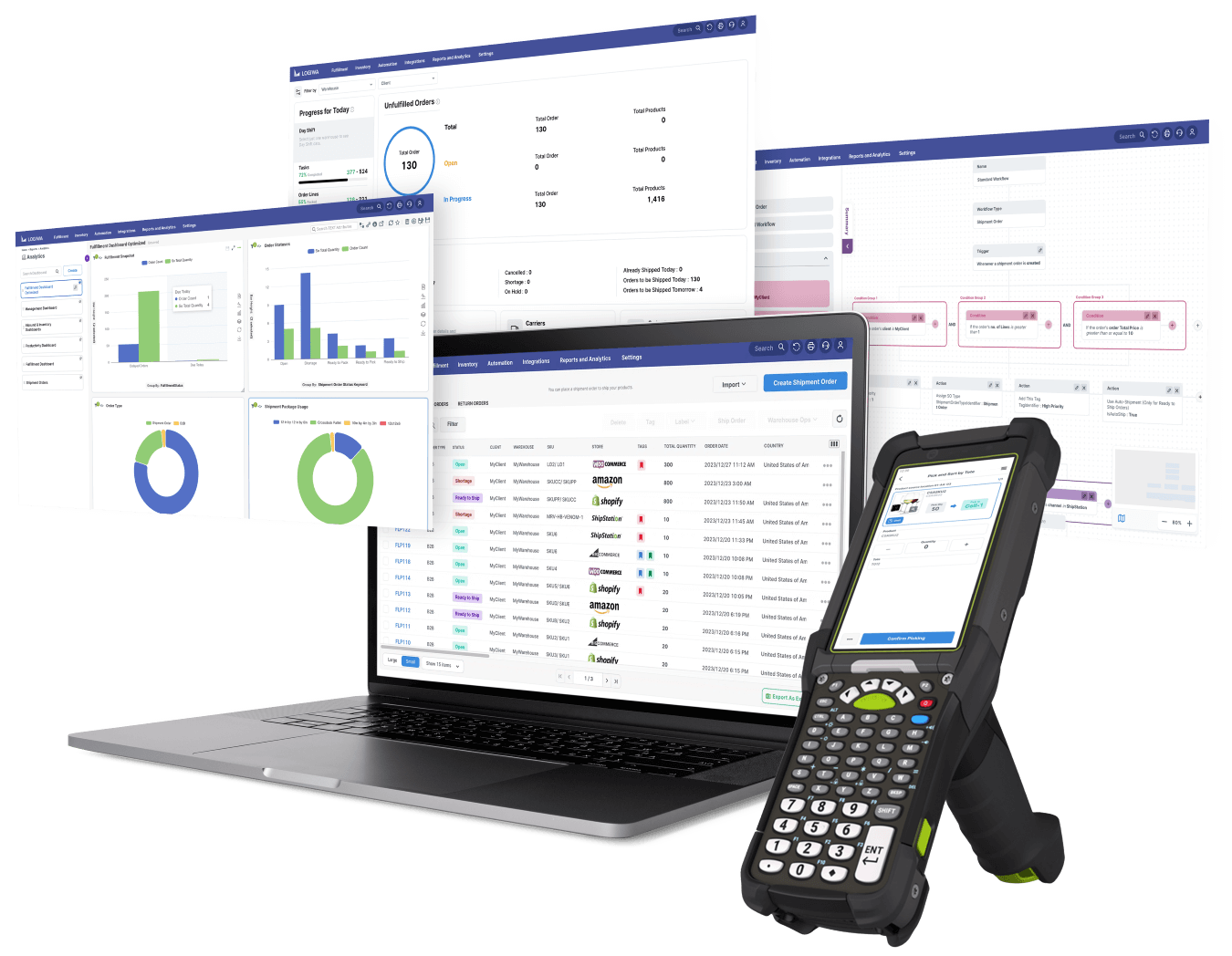

Logiwa’s Fulfillment Software has Everything 3PLs Need to Achieve High-volume Order Fulfillment Success

Check out all the functionality we provide and imagine all this power running on your mobile devices in a fully digital warehouse that’s part of your integrated fulfillment network. That’s Logiwa.

- Receiving

- Directed putaway

- Picking and packing

- PICK-FACE replenishment

- Return management

- Cycle counting

- Inventory transfers

- Multi-warehouse operations

- Multi-client operations

- Shipment rule automation

- DTC packing station

- Kitting and bundling

- Scale integrations

- Order routing

- Putaway automation rules

- Inventory allocation automation rules

- Automate picking job creation

- Shipment box suggestions

- Walking path optimization

- Put-to-wall

- Robotics in

During Peak Season Logiwa WMS Customers Experience

100% Order Accuracy

10x More Orders Shipped

More than just great software

We’re a high-volume Fulfillment Success Company.

As a true SaaS product, Logiwa WMS continually adds new features and innovations to drive your business forward. We solve your most pressing fulfillment challenges and help you meet the toughest industry standards.

Implemented in weeks,

not months

Logiwa IO is a true Cloud system that is easy to deploy, configure, and update as your business scales.

Optimized using AI

and automation

Our pre-built automation rules and AI powered jobs speed up everything from your inbound operations to your picking, packing and shipping processes.

Supported every step of

the way

Our customers rave about our customer support and we pride ourselves in our 7-9 minutes response time. We’re more than your software provider – we’re your partner for success.

Implemented in weeks, not months

Logiwa IO is a true Cloud system that is easy to deploy, configure, and update as your business scales.

Optimized using AI and automation

Our pre-built automation rules and AI powered jobs speed up everything from your inbound operations to your picking, packing and shipping processes.

Supported every step of the way

Our customers rave about our customer support and we pride ourselves in our 7-9 minutes response time. We’re more than your software provider – we’re your partner for success.

Pre-integrated with the leading ecommerce, marketplace, shipping, robotics, and accounting platforms.

FAQs about Fulfillment Software and Its Impact on Order Fulfillment

What is Logiwa's fulfillment network solution?

How does Logiwa’s fulfillment network software benefit my business?

Can Logiwa’s fulfillment network software be customized to meet my specific fulfillment system needs?

Logiwa’s fulfillment network software also allows for seamless integration with other systems, allowing for streamlined operations and reducing the risk of errors. Logiwa’s fulfillment network software has the ability to add, subtract, or modify features and ensures that the software will meet the specific requirements of your business, including those related to industry regulations, business processes, and operational needs. These customization options make Logiwa’s fulfillment network software a highly flexible and scalable solution for businesses of all sizes and types.

How does Logiwa’s fulfillment network software work?

How do I choose the right fulfillment network software for my business?

How is Logiwa’s fulfillment network software implemented in my fulfillment network?