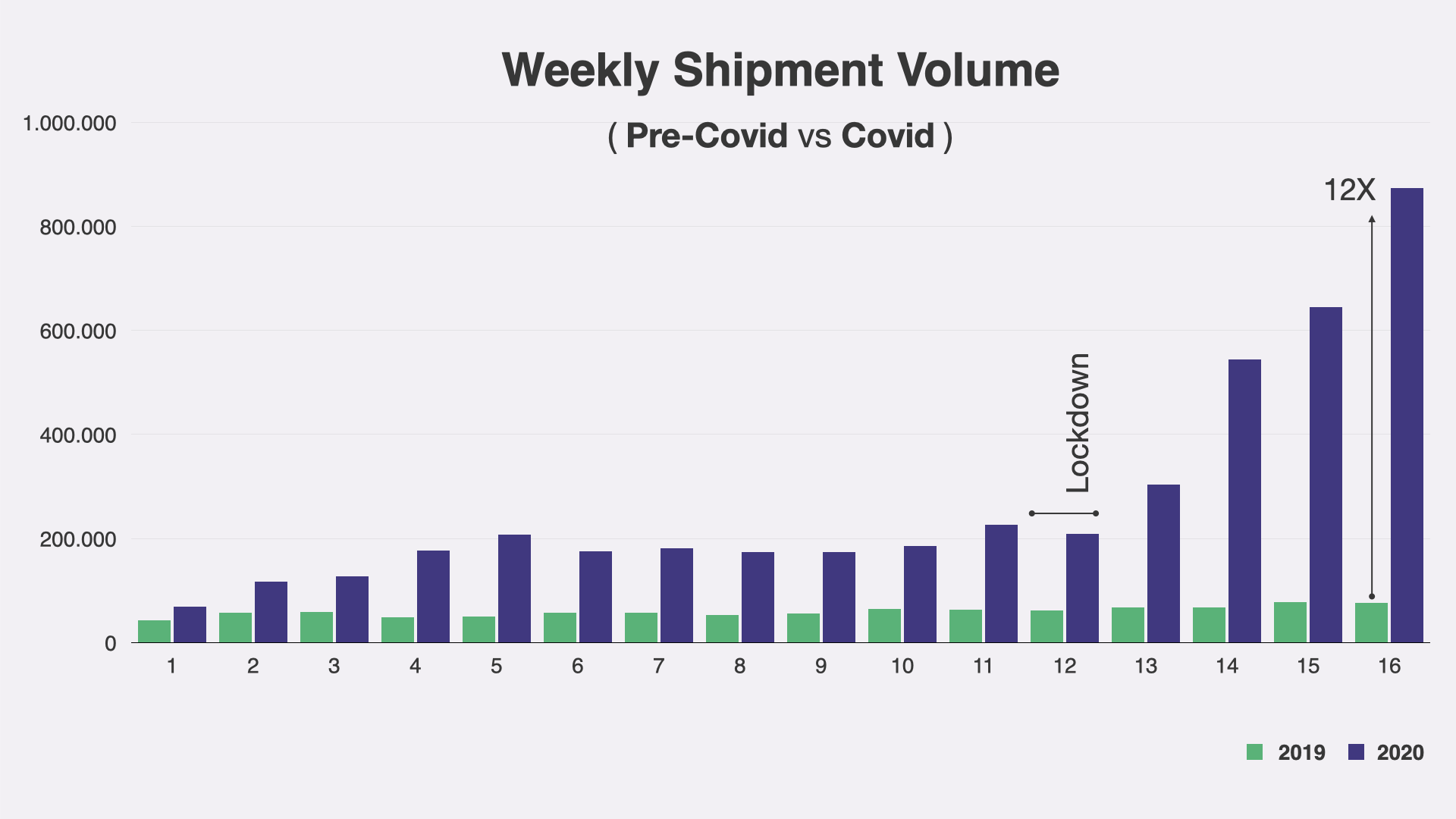

Our customers increased their number of shipments 12x relative to last year, heavily with the impact of Covid-19.

No question – all this already has a dramatic impact on the overall retail and supply chain. Most likely this will also result in online retail having a substantially larger bite from the overall retail market size post-covid. However, this is not certain as there is a high level of uncertainty in the whole world about when we will go back to “normal”.

While the whole world is at home, due to pandemic, supply chains can’t stop to get supplies to the communities. Logistics as being responsible for flow of goods within the supply chains is an essential business – especially warehouses that are the hubs of the flow are essential too.

We have been continuously mentioning “Agility in Supply Chains” as a huge advantage that a supply chain or its components should have. Pandemic and all its results and conditions have proven that agility is a crucial skill for a warehouse for the overall supply chain.

These agile supply chains had the ability to convert into B2C fulfillment chains that are capable of delivering a huge number of orders to consumers.

Warehouses represent the environments that are normally hard to keep social distancing between employees.

It is important to apply CDC Guidelines within the warehouses,

- Gloves and masks should be used according to CDC Guidelines

- The distance between employees should not be less than 6 feet at any given moment at anywhere in the warehouse

This is where it gets tricky. The purpose of this post is not to talk about CDC Guidelines but it is about redesigning the warehousing processes to align with these guidelines and to secure the well-being of the employees. Process redesign is crucial especially in labor intensive processes such as order fulfillment.

That’s why we come up with 3 specific fulfillment strategies to be applied in warehouses in order to align with CDC guidelines as well as provide social distancing.

- Very Small Warehouses with Average Shipment

- Small Warehouses with High Shipment

- Large Warehouses with High Shipment

Very Small Warehouses with Average Shipments

We recommend the “Pick and Pack” method in very small warehouses

A picker picks and then packs an order or a batch of orders in one trip and close the box

Of course, this strategy is going to reduce the efficiency of the pickers and packers. When the warehouse is not facing a drastic amount of orders, then this method is going to be the safest during a pandemic which guarantees social distancing and less touch points for employees

Small Warehouses with High Shipments

If a small warehouse faces a substantial increase in their number of orders, then the efficiency will be also important to keep the supply chain running and deliver supplies to the community on time.

We recommend the Batch Picking method in small warehouses

- WMS will batch the orders / picking tasks automatically on the rules and algorithms that are defined in the system.

- The rules should be primarily to keep pickers away from each other at a minimum of 6 feet.

- The batches that are picked in the warehouse will be taken to specific packers to pack the orders.

- Creating Fulfillment Teams (Cells) that will always have the same people in it will provide boundaries in the team to minimize the risk of transferring goods between different people.

- This will provide companies to also apply traceability and quarantine measures in case of a Covid-19 case in any of the teams (cells).

- A pick and pack team will do everything at the same frequency such as taking breaks, eating lunch. However, different fulfillment teams will do all these things at different times.

Large Warehouses with High Shipments

We recommend the Zone Picking (Pick and Pass) method in large warehouses.

In batch picking;

- The warehouse will be split into virtual zones next to each other. E.g. you can select 3 consecutive aisles as 3 zones.

- The WMS will create the tasks and batches for each zone automatically.

- A picker or a team of pickers will be responsible for each zone. That means the pickers are going to pick orders from the specific zones based on the picking tasks created.

An order may include items from all 3 zones. In this case the order will be split into 3 zones and different parts of the order will be picked from different zones by the employees responsible for those zones

- The WMS splits the orders into zones. E.g. we have 100 orders to be picked from 3 different zones.

- The WMS creates picking tasks automatically and it also creates a job for each zone that includes the picking tasks of each zone. Then Zone 1 starts executing Job-1.

- Picker-1 takes an empty cart, executes the picking tasks and picks the items into the cart. Then the picker completes Job-1 and leaves the cart to the transit spot of the zone for Picker-2 to take (if the zone is an aisle then it will be the frontline of the aisle).

- Picker-2 picks the cart from the transit spot and starts executing Job-2 for Zone-2. Picker-2 completes Job-2 just like picker-1 and leaves the cart at another transit spot for Picker-3 to pick the cart and do the same thing. So all items of the orders are consolidated in the same cart easily and safely.

- Picker-3 leaves the full cart to the packing station for the orders to be packed.

Some of our customers who liked this new pick and pass model so much, say they will continue using it after the COVID as well

As a result, with pick & pass method, no pickers contact each other and they keep the social distance of a minimum of 6 feet. They just touch the goods. In order to prevent any transmission through the goods and supplies, using gloves is mandatory as per the CDC Guidelines

Also, if an employee in any zone gets sick, only that specific zone can be locked down instead of the whole warehouse.

These methods will also have the advantage of eliminating paper and paper transfer between employees. Paper is a strong source of disease transmission so you will minimize the risk of transmission through materials.

Unlock a personalized tour of Logiwa IO

Related Terms

Holiday Order Fulfillment Strategy

To cash in during the most lucrative time of year, make sure to take revamp your holiday order fulfillment strategy. Here are a few holiday fulfillment strategies to keep track of.

Here is everything you need to know about eBay dropshipping and how you can dropship for eBay! Click here for futher detail on the ultimate eBay dropshipping guide

The best time to implement a new WMS is when you are moving warehouses. Moving your warehouse? Consider Logiwa’s latest tech WMS solutions to upgrade your logistics procedures.

The dark store concept, from the definition to the benefits is covered in Logiwa Blog. What is a dark store, finds the perfect answer in this article with related details.

The alcohol delivery industry is increasingly adopting DTC sales methods. Click now and learn more about alcohol shipping and alcohol delivery service!

Drone delivery is expected to revolutionize the supply chain by changing how retailers deliver. Click to find out more about various drone delivery systems.

Everything you need to know about kitting and assembly. How to make your operations more productive by implementing suitable kitting processes.

Optimize multi-warehouse and multi-client operations at both the macro and micro levels

Warehouse Management

Modern WMS cloud fulfillment powers a modern experience

Inventory Management

Improve your inventory across your supply chain.