Optimize Your Warehouse Order Picking Using Smart Order Routing

As you probably already know, order picking is a very labor-intensive process. As a result, it accounts for up to 55 % of warehouse management costs.

To help mitigate this cost, companies implement a process called smart order routing. When orders move through a company’s system in an intelligent manner, and workers are dispatched to pick items using a streamlined pick path, they spend less time moving back and forth and pick more items overall.

Smart order routing isn’t exclusively a cost saving exercise. It’s also a revenue generating exercise. When retailers fulfill orders accurately and on time, they increase their chances of repeat business. When they don’t do this, customer satisfaction – and the likelihood of recurring revenue – goes down as well.

Implementing smart order routing via an order routing system or order fulfillment software is an important part of keeping your warehouse competitive.

Contents

Inefficient Order Picking Negatively Impacts Warehouse Operations

A warehouse has two key objectives: keep goods safe and deliver goods to customers on time. Without a smart routing system, the picking process can negatively impact the latter goal.

Without an optimized pick path, workers move willy-nilly through the warehouse, resulting in a longer average pick time. This limits the number of items picked per shift, and goods may not make it to the outbound dock in time for delivery to the customer.

In addition to motion waste (the amount of unnecessary worker movements) there are other elements that take up time during the order picking process, including:

- Traveling between pick shelves

- Looking for items

- Picking items

- Setting up equipment for retrieval (e.g., forklifts)

In picker-to-part warehouses (where workers travel to the storage area with the items to be picked), operators try to reduce motion waste by limiting the distance that pickers walk by optimizing the order picking route. Many companies use warehouse management system (WMS) to respond dynamically to changes and create tailored pick paths to improve their order routing processes.

One of the biggest challenges that the pick path process must contend with is congestion. The key scenarios in which warehouse congestion occurs are:

- A picker travels to an aisle where another picker is already set up

- Multiple pickers arrive at the same aisle at the same time from opposite directions

To try to solve this, researchers have tinkered with different algorithms and strategies to enable smart order routing for pickers.

Standard Order Routing Strategies

Order routing strategies assume that a warehouse has double-sided aisles, since this type of layout typically outperforms single-sided picking strategies. Generally speaking, the effectiveness of an order routing strategy depends on:

- The order profile: An overall understanding of the orders your warehouse receives through statistical analysis.

- The storage strategy: How you approach your warehouse operations to receive, store, pick, pack, and ship goods (e.g., warehouse management system; picking processes, etc.).

- The warehouse layout: How you set up your warehouse layout , your staging area, and shelves, the width of your aisles, etc.

| Method | Description |

| S-Shaped (i.e., Traverse Strategy) | Workers move around the warehouse in a curved, “s-shaped” manner. Rather than moving through aisles that don’t have the items they need, their pick route directs them to travel directly to the aisle they need. One of the most frequently used methods, this is best when the number of picks items per aisle is high. |

| Largest Gap | Pickers enter an aisle, but how far into the aisle they travel is determined by how far the longest gap is. A gap is the length between two adjacent pick items, or the space between the last pick item and the back aisle. This is best to use if there is a low number of pick items per aisle. |

| Hybrid | This method combines the S-shaped Method with the Largest Gap Method. Which approach is used depends on which method is the most efficient for a given pick. At the end of each pick, there’s a choice to make: whether to continue on to the end of the aisle or turn around and return to the front of the aisle. |

The ACO-Based Routing Algorithm with VLC Support Approach

While “ACO with VLC” may seem like nothing more than alphabet soup, its letters are meaningful.

ACO stands for Ant Colony Optimization while VLC stands for Visible Light Communication system. In order to understand the larger algorithm, you’ll need to understand these two terms individually.

Ant Colony Optimization (ACO) Based Routing

As the name implies, the ant colony optimization (ACO) algorithm gets its inspiration from ants. Ants seek the best route from the colony to food. To start, they take off in a random direction. Once they’ve selected a path, they leave behind pheromones. When more ants take a particular path, more pheromones are left on that route. An increased amount of pheromones on one path increases the likelihood of other ants taking that route. Academics use this to create a formula that considers the probability and desirability of different paths.

Visible Light Communication (VLC) System

A visible light communication (VLC) system is one type of indoor positioning system that allows warehouse workers to quickly identify objects and people. While the ACO-based smart order routing solution uses VLC, there are other types of indoor positioning systems on the market.

How Do ACO and VLC Work Together in This Method?

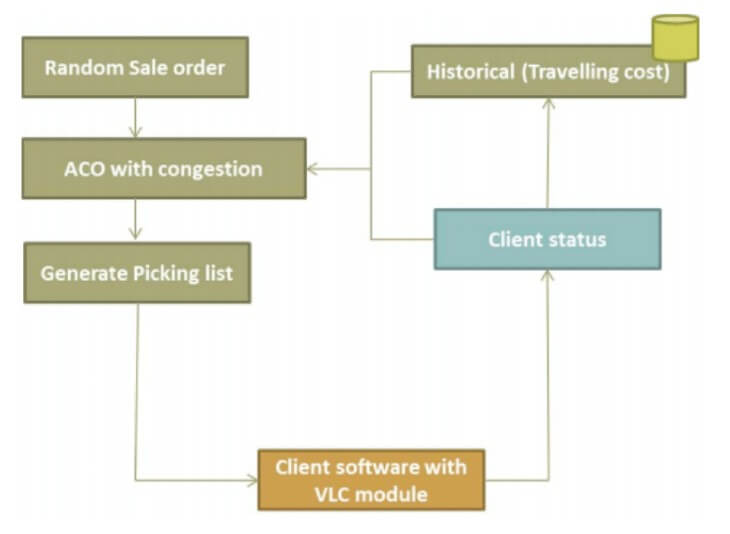

A warehouse integrates the ACO algorithm into its workflow, which may already include a VLC system, in the following way:

- A random customer order enters the system

- The order moves through the ACO algorithm to consider potential congestion

- The system generates a picking list based on the output of the ACO algorithm

- The picking list enters the client’s system, which includes VLC

- The VLC helps workers identify which items to pick next/where there are already people navigating aisles

- Information like the client status and the historical traveling cost are constantly fed back into the ACO algorithm for continuous improvement

Figure 1: ACO with VLC support workflow (Source)

In other words, the ACO initially determines an individual picker’s route (much like the first few ants that leave the colony). Real-time data through technology like the VLC system then further coordinates and optimizes a picker’s path or order routing.

Better Warehouse Performance = Higher Profit Margins: Logiwa syncs accurate data across your entire interface so the inventory numbers you see on your dashboard are what your employees see on their devices. Learn how Logiwa uses real-time data to help you get up to 100% inventory accuracy and 2.5x shipments.

Smart Order Routing System For Warehouses With a Middle Aisle

Typically, businesses construct warehouses using a fairly generic layout. There are several parallel aisles, a central warehouse depot where items are stored in bulk, and options for moving between aisles at the front of the warehouse and the back of the warehouse. In this kind of warehouse, the standard solution for optimizing the pick path uses the S-shaped curve. With this approach, workers skip aisles they don’t need, weaving past them in a curve towards aisles with the necessary items.

On the other hand, some warehouses have “middle aisles.” Workers can change aisles not just from the front end and the back end of the aisle, but from the middle as well. This layout calls for a more optimized order routing approach that goes beyond the standard S-shaped method.

Designing a smart order routing system for warehouses with a middle aisle requires 2 main steps:

- Modeling the warehouse and its component parts using graph theory

- Finding the shortest order route using a dynamic programming formulation

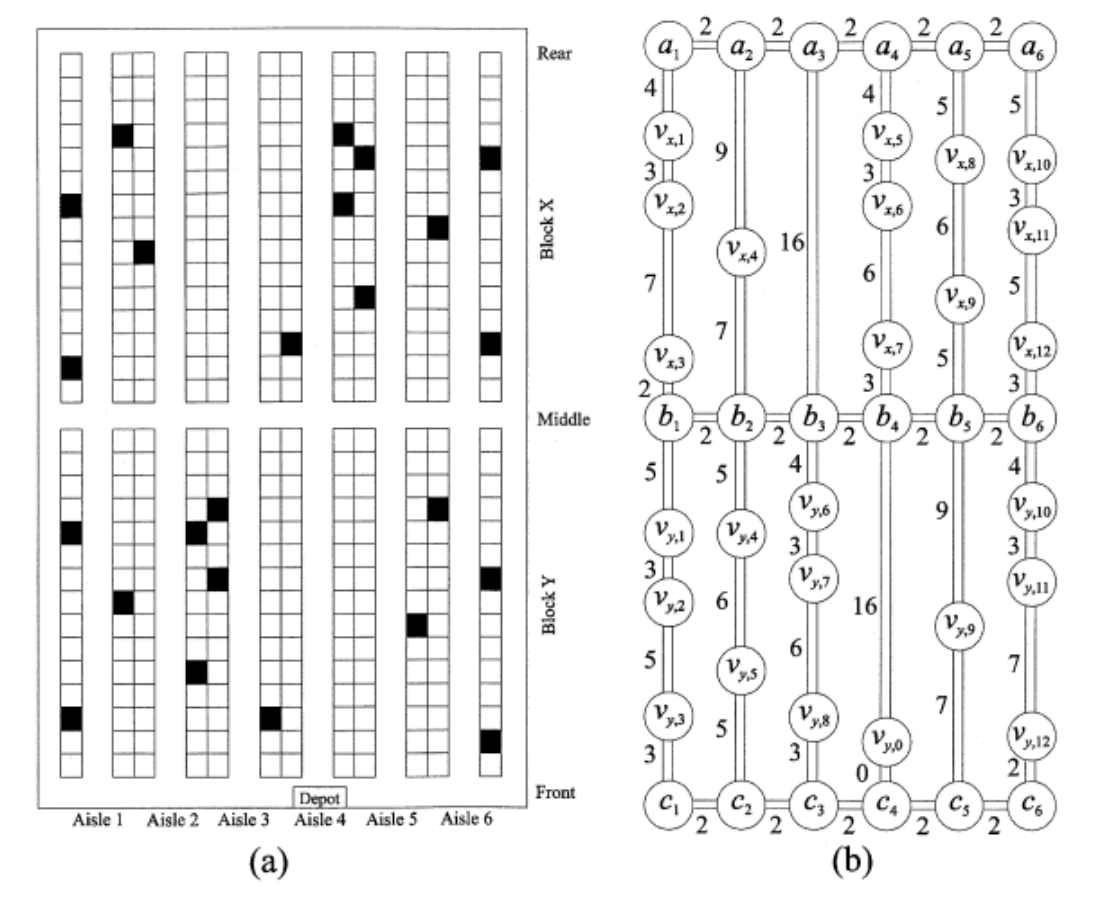

Modeling The Warehouse Using Graph Theory

Modeling the warehouse begins with a few key assumptions:

- The warehouse aisles are lined up in a parallel manner

- The warehouse stores items on both sides of the parallel aisles

- The warehouse layout enables order pickers to switch aisles on either end (front and back of warehouse) and through the middle aisles

- The order pickers can collect items for an individual item in a single tour

- The order picker drops off items at the central depot where they receive instructions for the next picks or tour

In most cases, it also holds that the items within individual orders are spread throughout various aisles in the warehouse.

Subsequently, managers use the following variables to understand their warehouse layout graph.

- Identify your overall warehouse graph as G

- Indicate the number of aisles as n aisles

- Indicate the first block of aisles as block X and the second block of aisles as block Y. (Remember that there are two blocks of aisles, since there is a middle pathway that provides a third route for changing aisles)

- Indicate the number of items to pick as m aisles

- Indicate the items in block X as mx

- Indicate the items in block Y as my

- Remember that m = (mx+my)

Once this is done, the entire warehouse can be modelled as a graph with the following vertices:

| Vertices | Pick Location |

| vx,i (i = 1, … , mx) | Block X |

| vy,i (i = 1, … , my) | Block Y |

| ai (i = 1, … , N) | Rear end of Aisle i |

| bi (i = 1, … , N) | Middle end of Aisle i |

| ci (i = 1, … , N) | Front end of Aisle i |

| vy,0 | Depot |

Whenever two vertices match with side-by-side item locations, connect them with two vertical edges. The length of these edges represents travel durations within the warehouse.

Order picking routes or tours are tour subgraphs represented as T of the warehouse graph G. In order for a tour to be considered a tour subgraph, its edges must create a cycle that includes:

- The central warehouse depot

- Each pick location (at least once)

This subgraph is integral to finding the “shortest order picking tour.” A warehouse manager can find a subgraph’s length by adding up the length of all the edges in a given subgraph. As a result, discovering the shortest order picking route is a matter of identifying a tour subgraph T of the warehouse graph G that has the shortest length.

Figure 2: Conceptual warehouse representation versus graphic warehouse representation with pick locations identified (Source)

Once this graph exists, an algorithm based on tour subgraphs and partial tour subgraphs works together with dynamic programming to deliver the minimum tour subgraph. While this would be incorporated into a warehouse management software for non-computer-science-savvy individuals, interested warehouse managers can study the algorithm and its component parts in detail.

Applying the Middle Aisle Order Routing Algorithm

Notably, “middle” aisles don’t need to actually be in the middle for a warehouse to apply this algorithm. The “middle” aisle can be located closer to the front or closer to the end of the warehouse, leading to an uneven block X and block Y.

Moreover, even warehouses with only one or two “switch points” can use this algorithm as well, so long as they adjust the distances between aisles accordingly.

Overall, it’s a tricky algorithm, and it’s a beast to implement, but, once incorporated, it makes smart order routing within warehouses incredibly quick.

Unlock a personalized tour of Logiwa IO

Using Technology for Your Smart Order Routing System

As a simpler alternative, warehouses can purchase off-the-shelf smart order routing software. For instance, automated order routing (AOR) streamlines the process of tracking order containers and routing them to the correct spot in a distribution center. This system talks to the software running the conveyor system to receive barcode and carton data. Features of a great AOR include:

- Hardware agnostic: You’ll need an AOR that works with any brand of warehouse equipment or software

- Modularity: You’ll have unique warehouse problems and you want an AOR that can be configured and customized to adapt

- Future-proof: It should be designed to easily accommodate future changes or configurations as your business and the marketplace evolves

An AOR may prove to be a necessary part of your warehouse management technology suite, especially if you seriously need to optimize your order management and picking methods.

Smart Order Routing Reduces Lost Time and Money

Order picking is an expensive, but unavoidable, part of running a warehouse. A large part of this expense comes from labor. Warehouses can cut down on unnecessary labor costs by ensuring that when their workers navigate a warehouse, they’re taking the most efficient route. Consequently, smart order routing helps reduce lost time, save valuable money, and get orders to your customers sooner rather than later.

Scale up B2C fulfillment operations with an integrated digital warehouse and fulfillment system

Inventory Management

Improve your inventory across your supply chain.