Bullwhip Effect – Definition, Causes, and Impacts on Supply Chain

In every business, customer-oriented demand fluctuations take as a standard to some degree. A retailer sells 100 packs of socks one month, while the same retailer doubles the sales next month. Of course, this is not a one-way journey. The increasing demand from the end customer travels till it reaches the manufacturer in more giant waves. This article includes the definition of the bullwhip effect and the information on how to reduce it with proven methods. If you also want to answer the question “What is the bullwhip effect in the supply chain?” reading the rest of the article may help you better understand the bullwhip effect concept.

Contents

What is Bullwhip Effect?

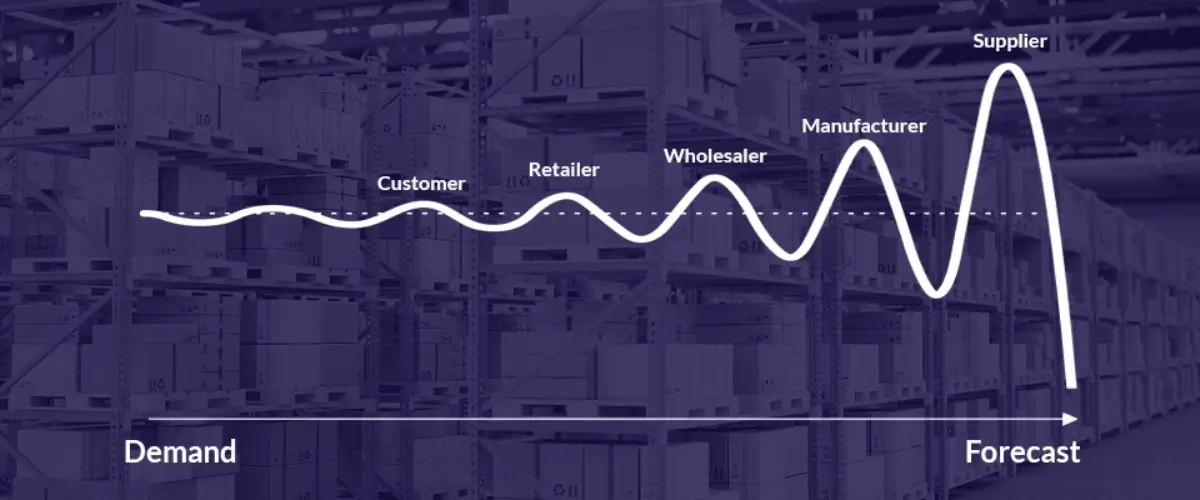

When you look it up, the bullwhip effect meaning is almost as follows: The bullwhip effect is a supply chain phenomenon in which demand forecasts yield supply chain inefficiencies. This definition is quite enough to understand the concept roughly. Imagine you holding a long whip in your hand, and if you snap it a little bit, it begins to wave slowly. Just like this example, the bullwhip effect name after the physics rule involved in cracking a whip. When the person holding the whip nudges the whip at the handle, the first movement causes the wave patterns to amplify in a chain reaction. The question “What is the bullwhip effect?” can easily be explained like this. The demand coming from the end customer changes the order circle on the retailer side, and it goes on with more considerable fluctuations till it’s at the manufacturer’s door. The bullwhip effect can explain as an occurrence detected by the supply chain where orders sent to the manufacturer and supplier create more considerable variance than the sales to the end customer. This variance can ruin the smoothness of the traditional supply chain process as each interruption will miscalculate the product demand ending up in exaggerated fluctuations.

After the comprehensive definition of this concept, you will also know the causes of the bullwhip effect and some straightforward solutions to minimize it.

How To Reduce Bullwhip Effect?

Businesses have their unique supply chain, inventory management challenges, and complexities. Every company in every industry finds a way to get out of those hardships sooner or later. However, if you own the proper armor for cracking the bullwhip effect, a 15-35 percent reduction of stock-out situations and missed customer orders may be possible. Let’s see how to reduce the bullwhip effect with commonly recommended methods down below.

Request an online inventory management system demo and see why thousands of companies are using Logiwa.

Seeing the Existence of Bullwhip Effect

If you notice a fluctuation in the supply chain for a while, the first and most crucial step to be taken is accepting the bullwhip effect. The only key to recognize the concept and combat against it with the right weapons. Many companies do not understand that they have high buffer inventories throughout their supply chain. All they need is a thorough analysis of stock points, beginning from stores to raw material manufacturers. Only this can help you unveil the idle excess inventories and take precautions. Supply chain executives in companies can further analyze the reasons behind these excess inventories and set tone norms.

Better Communication & Collaboration

In the company and among the customers, suppliers, distributors, manufacturers, and the rest of the partners, better alignment and communication is a must. Because if suppliers better understand the customer needs, they can quickly solve excess inventory problems.

Using Forecasting Tools

Inventory and order management software tools help you enable more accurate customer demand projection. It will also make you see what is happening along the supply chain. In the end, you will have more consistent order placement, customer demand, and sales figures.

Inventory Planning Process

Companies need to periodically review and adjust their safety stock settings along with the minimum-maximum stock range of each inventory point. Inventory balance according to regional demands coming from customers.

Raw Material Planning Process

Procurement managers are generally prone to ordering in advance and keep high buffers to avoid disruption in production. Raw material planning needs to put in the production plan carefully, and the production plan needs to be released in advance to align with the purchasing lead times. For example, for similar raw materials, integration from a large vendor base to a smaller one will improve the supplies’ flexibility and reliability, resulting in lower raw material inventories.

Grab a Demand-Driven Approach to Supply Chain Management

When you see the market demand and reply accordingly, you can better manage your order in more accurate ways. This demand-driven approach relies on a system of coordinated processes to gain insight into supply chain movements and react quickly. Many of the topics above, especially Better Communication & Collaboration and new technologies to enable supply chain visibility, are used by demand-driven approaches. Here, each company needs to decide on its push-pull strategy. The push approach will be better for stable products, while the pull strategy is for more erratic demand.

Optimization of MOQs

Minimum order quantities can be pretty changeable according to customer demand, product type, and so on. With high minimum order quantity products, high gaps between subsequent orders will be inevitable. Lowering the MOQ to an optimal level is the only key in this case. This action will provide smoother order patterns. Additionally, instead of offering frequent promotions, maintaining stable pricing throughout the year may help you have regular and predictable demand.

With all these methods above, you have a piece of solid knowledge on how to handle a bullwhip effect. Now it is time to get some idea about the causes and examples of the bullwhip effect. Moreover, if you want to understand and apply the Minimum Order Quantity for your business.

The Bullwhip Effect in Supply Chain with Example

In some periods, the demand in order may change to a certain extend. This normal situation sometimes causes retailers to become highly reactive to customer demands. At this point, bullwhip effect examples start to occur. Say that you are a shop owner, and you usually sell 30 seabeds a day. However, one day extraordinarily, you deal with 65 seabeds and start to think of increasing the order on the manufacturer side. Communicating with the distributor, you double up the order. The distributor calls the manufacturer with the same reflex and increases the demand more than what the retailer said. This bullwhip in the supply chain example is remarkably simplified but reflects increasing fluctuations as actions and reactions going on the chain.

You may also like:The dark store concept, from the definition to the benefits, is covered. The details are here if you are interested in taking your retail business to a higher level by opening a dark store.

What Causes the Bullwhip Effect?

Causes of the bullwhip effect may stem from many different reasons. At every stage of the supply chain, there are possible fluctuations and disruptions, which influence the huge supplier orders. Including inventory, changes in customer demand directly affect all the other factors along the chain. However, the bullwhip effect can occur even in relatively stable markets where the order is essentially constant.

Predicting customer demand has always been difficult as it depends on many different variables. The following list below names a few of these variables:

- Counting on the old demand information to forecast the current demand information does not allow any fluctuations in demand over some time.

- Frequent cost changes and special discounts can upset regular buying patterns. When brands offer discounts, customers want to take advantage of those prices, and this causes uneven production and distorted demand information.

- Companies may fulfill their orders weekly or monthly. Creates variability as there may be a rise and fall in demand at a particular stage followed by no request after.

- Sometimes, customers overstate their demands on purpose due to shortages, and when the supply becomes adequate again, they cancel the order. In this case, if the retailer has a return forfeit, exaggerated needs and order cancellations can avoid.

- Miscommunications in the supply chain links may cause distortions in the process. Related staff take demands quite differently within various links and order the product differently.

Impacts of Bullwhip Effect on Supply Chain

The bullwhip effect, a.k.a Forrester effect, results from the overreaction of companies to customer demands. Once they sense an increase in the market, they tend to reflect this rise to the other links in the supply chain. Distributors and manufacturers are the elements in this link that reply to this reaction in the same manner. This fluctuation gets more prominent when it reaches the last ring. The situation disrupts the companies’ supply chain and has solid consequences for businesses as a whole.

- If the customer demand is less than usual, there is excess stock with the retailer or distributor, resulting in understocking. For example, a pencil seller usually places 500 packets of pencils every summer before back to school. But since the last two summers, he observed that the pencils sold lesser and lesser every summer. So this summer, he orders for 300 packets only. But it so happened that the pencil company cut the prices per packet by a considerable amount. Unfortunately, it resulted in stock-out situations.

- If there is excess order of the product following a stock out, the tendency is to see extra charges. Continuing with the above example, the seller decides to order a few more pencil packets to avoid storing and overcompensating them. So taking the demand and the price reduction into consideration, he contains 600 boxes of pencils. However, customers may not want to buy any more pencils for different reasons.

FAQs

What is the bullwhip effect in supply chains, and what causes it?

The bullwhip effect is a distribution channel phenomenon that shows instabilities and fluctuations in product/orders within a supply chain. Also called “the Forrester effect,” it shows inefficiencies in inventory levels caused by demand distortions and inaccurate forecasting. The reason this is called a ‘bullwhip effect’ is because the amplitude of a whip continues to increase during oscillation. As the wave moves away from the source, the deviations in wave pattern increase. In terms of supply chains, this means that growing or waning customer demand has direct implications and influence over inventory levels.

Is the bullwhip effect negative?

The bullwhip effect can have adverse effects on inventory, shipping time, and operational costs. Orders based on misguided forecasts lead to incorrect stock levels and often excess inventory. This can be costly due to the fact that it wastes resources if consumer/buyer demand fails to increase. Moreover, insufficient inventory, unfulfilled orders, and advertising non-purchasable products can undermine trust in customer relationships and severely affect a business’s profitability.

Why is the bullwhip effect important?

It helps with evaluating the supply chain and optimizing supply chain management. At various stages in a supply chain, key factors such as time and order decisions, supply demand, lack of communication or other irregularities can cause a bullwhip effect, one of the most common obstacles in supply chain management.

How can you prevent a bullwhip effect from occurring?

Methods for preventing a bullwhip effect from occurring include: leveraging technology that focuses on visibility and metric data, reducing the size of orders, offering good product prices to avoid buyer surges, improving customer communication, and minimizing customer order cancellations to ensure consistent ordering patterns.

Unlock a personalized tour of Logiwa IO

FAQs

What is the bullwhip effect in supply chains, and what causes it?

The bullwhip effect is a distribution channel phenomenon that shows instabilities and fluctuations in product/orders within a supply chain. Also called “the Forrester effect,” it shows inefficiencies in inventory levels caused by demand distortions and inaccurate forecasting. The reason this is called a ‘bullwhip effect’ is because the amplitude of a whip continues to increase during oscillation. As the wave moves away from the source, the deviations in wave pattern increase. In terms of supply chains, this means that growing or waning customer demand has direct implications and influence over inventory levels.

Is the bullwhip effect negative?

The bullwhip effect can have adverse effects on inventory, shipping time, and operational costs. Orders based on misguided forecasts lead to incorrect stock levels and often excess inventory. This can be costly due to the fact that it wastes resources if consumer/buyer demand fails to increase. Moreover, insufficient inventory, unfulfilled orders, and advertising non-purchasable products can undermine trust in customer relationships and severely affect a business’s profitability.

Why is the bullwhip effect important?

It helps with evaluating the supply chain and optimizing supply chain management. At various stages in a supply chain, key factors such as time and order decisions, supply demand, lack of communication or other irregularities can cause a bullwhip effect, one of the most common obstacles in supply chain management.

How can you prevent a bullwhip effect from occurring?

Methods for preventing a bullwhip effect from occurring include: leveraging technology that focuses on visibility and metric data, reducing the size of orders, offering good product prices to avoid buyer surges, improving customer communication, and minimizing customer order cancellations to ensure consistent ordering patterns.