The competition in ecommerce is fierce. Among fleeting brand loyalty, just one subpar experience can have your customer making their next purchase from your competitor.

Arguably, the key to delivering the positive experiences that keep your customers coming back lies within the efficiency of your fulfillment operations.

This then begs the question – what type of facility do you need to operate, a warehouse or a fulfillment center?

When weighing warehouse vs. fulfillment center, consider which option gives you the maximum competitive edge and enhances the end customer experience with fast shipping times and a frictionless return experience.

Here we dig into the differences and uses of warehouses and fulfillment centers and their roles in the supply chain. The goal – to better position you to choose the facility operations type best for your fulfillment business.

Contents

- Warehouse vs. Fulfillment Center: Definitions and Use Cases

- Key Differences Between Warehouses and Fulfillment Centers

- The Role of Warehouses and Fulfillment Centers in Supply Chain Management

- Consider These Factors When Choosing Between a Warehouse and a Fulfillment Center

- Future Trends in Warehousing and Fulfillment Solutions

- Always Prioritize Your Business Needs When Selecting a Fulfillment Partner

- Try Logiwa IO Fulfillment Management System and Start Fulfilling Brilliantly

Warehouse vs. Fulfillment Center: Definitions and Use Cases

Warehouse

A storage facility for goods as they await distribution to their next destination in the supply chain. Its most basic use is for long-term storage.

Fulfillment Center

Usually a commercial space that stores, processes, and delivers customer orders on behalf of ecommerce businesses. The most dominant role of fulfillment centers is to process and ship high volumes of DTC orders quickly.

Most fulfillment centers offer end-to-end logistics. This means they can procure, receive, and store inventory, then process online orders, ship, and manage any product returns on behalf of businesses.

Key Differences Between Warehouses and Fulfillment Centers

Despite the many similarities, a warehouse and a fulfillment center are fundamentally different in the following ways:

- Storage duration: Warehouses are best for long-term storage, while fulfillment centers are ideal for short-term storage. Typically, warehouses invest in more storage space than fulfillment centers, making them the most cost-effective option for slow-moving inventory.

- Services offered: Warehouses focus on essential logistic services like inventory storage and management. Fulfillment centers, on the other hand, offer extra logistic services such as shipping, packing, order processing, tracking, and delivery.

- Primary operational focus: A warehouse’s central focus is inventory storage and management, while a fulfillment center’s primary focus is fast order processing and product delivery.

- Product turnover: Warehouses store products for long periods and experience less traffic thanks to static storage. Fulfillment centers handle and process higher volume of products quickly and experience more traffic from their extra activities like product shipping.

- Preferred location: A warehouse’s ideal location is one with ample space to facilitate bulk storage and close to crucial infrastructure. Thus, city outskirts, industrial zones, and areas near airports, seaports, and railways are perfect locations. Fulfillment centers prefer city locations with well-established infrastructure to access customers swiftly.

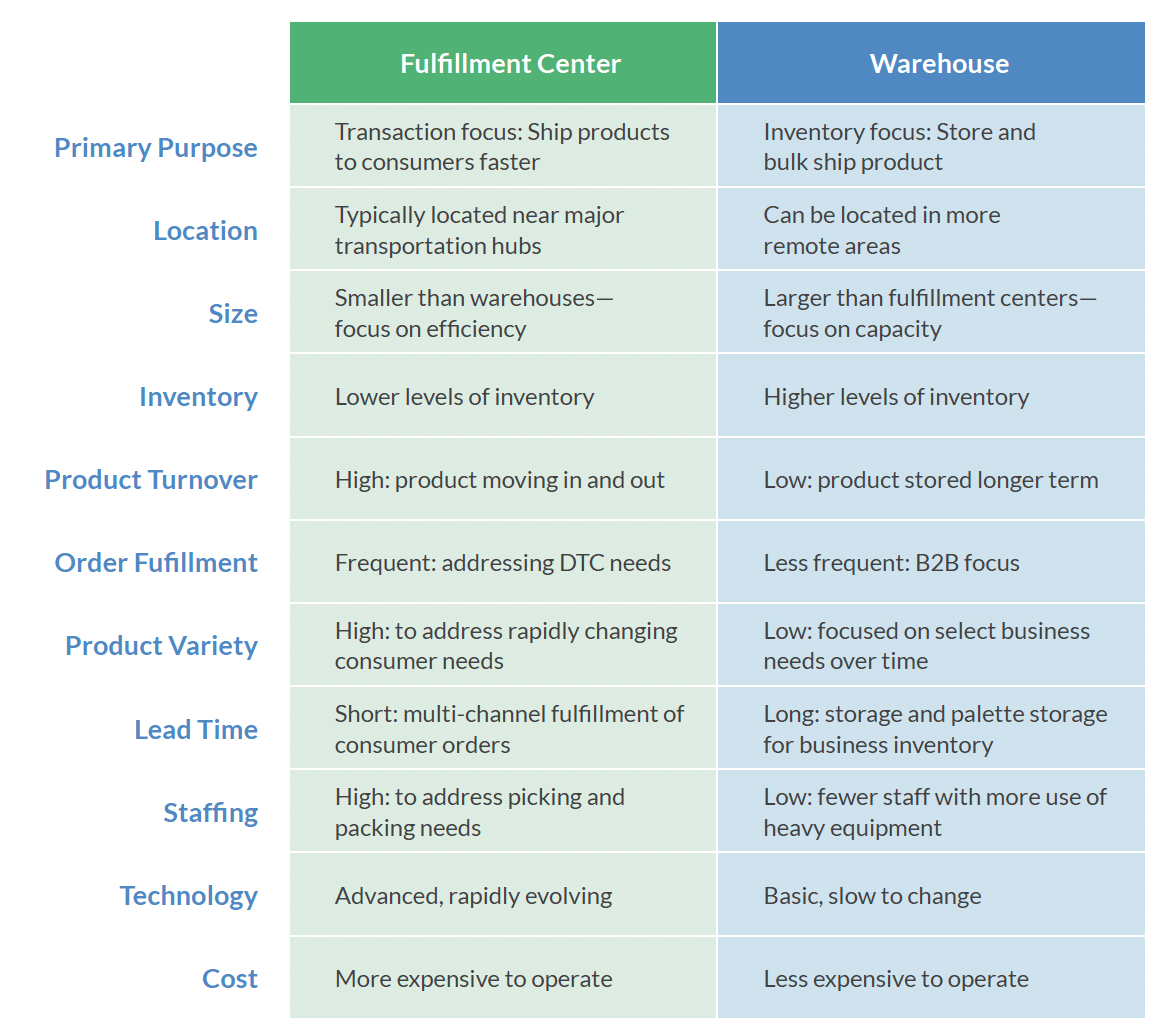

Check out this infographic table highlighting more differences between warehouses and fulfillment centers.

Unlock a personalized tour of Logiwa IO

The Role of Warehouses and Fulfillment Centers in Supply Chain Management

The primary functions of traditional warehouses in supply chain management include:

- Ensuring efficient space usage: Warehouse space is optimized to facilitate storage and operations efficiency. The warehouse layout and the organization of warehouse operations are geared towards increasing warehouse space efficiency.

- Enhancing inventory accuracy: Warehouses track business inventory levels and generate real-time alerts. This helps companies manage supply and demand to avoid stockouts or overstocks.

- Integrating with other systems in the supply chain: A warehouse’s management system integrates with supply chain management including ecommerce platforms.

The primary roles fulfillment centers play in the supply chain include:

- Inventory flexibility: Fulfillment centers leverage inventory data and relevant industry information to predict demand and advise businesses when to scale their inventory up or down. This stabilizes the supply chain and helps companies avoid market surpluses and shortages.

- Rapid order delivery: Fulfillment centers empower ecommerce businesses to offer on-demand delivery by expediting order processing and shipping, keeping the supply chain flowing fast.

- Optimizing fulfillment costs: Fulfillment centers make product delivery more cost-efficient and consistent, helping to benchmark delivery costs and stabilize supply chain costs.

Consider These Factors When Choosing Between a Warehouse and a Fulfillment Center

The truth is warehouses and fulfillment centers offer many overlapping or identical services. However, here are four factors to consider when determining what fulfillment model makes the most sense for your business.

Business Model

Is your business model B2B or DTC? Fulfillment centers are better equipped for DTC fulfillment because they offer last-mile delivery services. B2B ecommerce stores that bulk ship merchandise to regional suppliers would likely find a warehouse’s inventory management services more reliable and efficient.

Inventory Type and Volume

Who is better equipped to handle the type of inventory you deal in? For instance, if you trade perishable commodities, the go-to partner must have cold storage and refrigerated transport.

Also, consider how much inventory you will need to keep in storage. Warehouses suit businesses with slow-moving inventory that stays in storage longer, while fulfillment centers are ideal for fast-moving goods.

Customer Location

Do you need to prioritize a fulfillment partner close to your customers’ location to ease delivery logistics? Typically, fulfillment centers are closer to cities and large towns than warehouses, and they’re often the best fit if most of a company’s clientele resides in urban areas.

Shipping and Handling Requirements

Goods such as hazardous products and oversized packages require special permits and handling equipment to ship safely. Be sure to prioritize a partner who meets your shipping operations’ specific legal and infrastructural needs.

Future Trends in Warehousing and Fulfillment Solutions

Artificial Intelligence (AI), data analytics, robotic process automation, and machine learning are the leading technologies spurring innovation in both warehousing and fulfillment. Some of the emerging trends include:

- Optimizing order fulfillment using integrated software solutions such as fulfillment management systems

- Demand forecasting using advanced data analytics

- Inventory optimization and warehouse digitization using advanced software solutions like a warehouse management system

- Warehouse automation using robotic picking systems, autonomous mobile robots, retrieval systems, and automated storage

- Warehouse pick path optimization and smart storage using AI

These trends enhance operational efficiency, optimize labor costs, and empower businesses to make data-backed decisions. Warehouses and fulfillment centers that adopt and implement these innovative technologies boost their competitive edge by delivering better order fulfillment services without snowballing operational costs.

Always Prioritize Your Business Needs When Selecting a Fulfillment Partner

Ultimately, specific business fulfillment needs should guide the decision to whether you need a warehouse or a fulfillment center. For instance, an ecommerce store may prioritize bigger warehouse space if it usually stores bulk inventory for extended periods. But if a store sells fast-moving goods like skincare products, it should prioritize fast order processing capabilities.

Create a list of must-have qualities and use it to assess whether a warehouse or fulfillment center is the right fit. For instance, an ecommerce store may prioritize bigger warehouse space if it usually stores bulk inventory for extended periods. But if a store sells fast-moving goods like skincare products, it should prioritize fast order processing capabilities.

Try Logiwa IO Fulfillment Management System and Start Fulfilling Brilliantly

Logiwa IO, an AI-driven Fulfillment Management System (FMS) is revolutionizing DTC, B2B, and third-party logistics operations. Our FMS helps fulfillment providers optimize their processes thanks to real-time visibility, intelligent automation, and multichannel order processing. With Logiwa IO FMS, fulfillment providers can quickly connect with new online stores and marketplaces, making it easy to run a digital warehouse.

Request a demo today and start your journey to high-volume fulfillment success.

Deploy Logiwa IO across all your fulfillment centers quickly with our cloud-based infrastructure

Warehouse Management

Modern digital WMS powers a modern fulfillment experience