Why Every Second Is Crucial in Ecommerce Warehouses

Have you ever thought about how long it takes to pick, pack, and ship an item? When you’re working out how to manage your Ecommerce warehouse, every second matters.

The time it takes for a picker to scan the location, scan an item, and then enter its quantity may seem like an insignificant amount of time, but added up, the time it takes can be the equivalent of a full workday.

BONUS: Before you read further, download our Warehouse Management Software Whitepaper to see how Logiwa uses real-time tracking to help customers get up to 100% inventory accuracy and increase shipments by 2.5x.

How to Save Time in an eCommerce Warehouse

One of the easiest ways to save time for you and your workers is implementing a warehouse management system (WMS) in your eCommerce warehouse. Using a WMS is a great way to manage multiple orders at once and optimize things that can take up a lot of time, such as walking time within an eCommerce warehouse. However, did you know that a WMS can even save precious seconds by optimizing scanning processes as well?

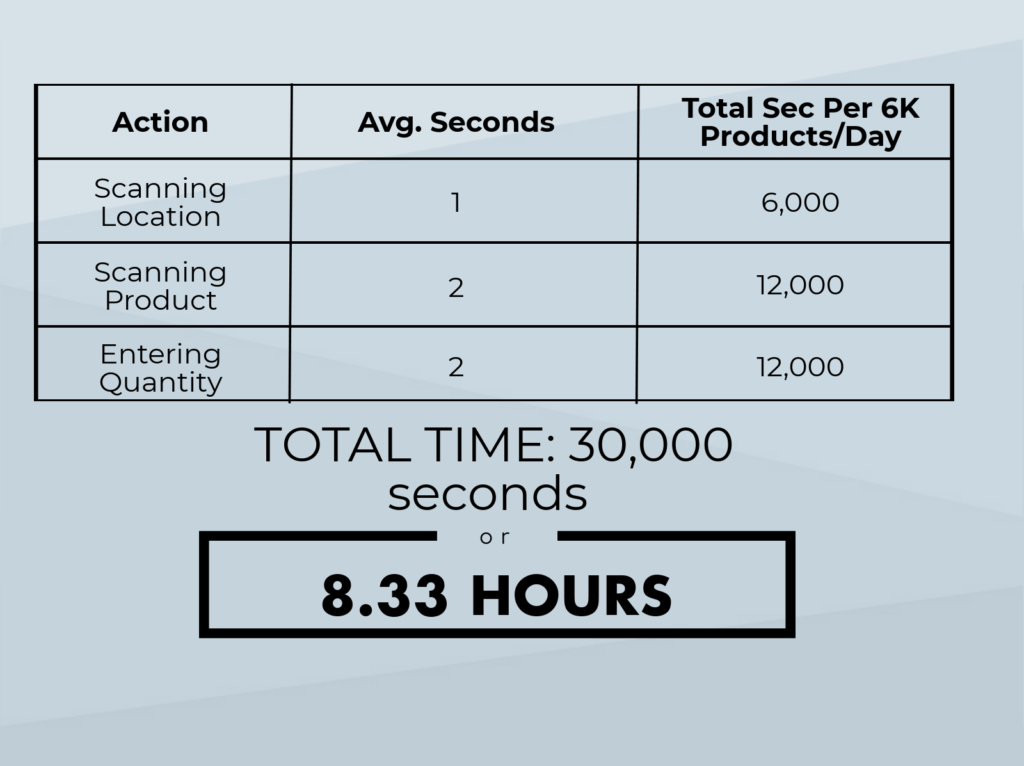

Take, for example, an average eCommerce order. Let’s say that the average number of products per order is 2 to 3. If the median number of orders is 2,000 per day, then let us assume our workers are picking around 6,000 products per day. This example will not include walking time or picking cart location time, but will solely focus on the seconds spent scanning a location and entering the product and quantity.

When your picker approaches the location they are going to pick an item from, they must first scan the location. Scanning the location barcode is easy, since workers can usually easily spot the scanning area. This action can take, on average, one second to do.

Now let’s look at the next step in the process. The next step for the picker is to select the item, and scan the product. Scanning the product itself is what we will focus on here, since selecting the item from amongst a jumble of others can take time as well. Finding the barcode to scan on a product can take longer than scanning a location, since the barcode might not be immediately within view. Let us say that this action can take, on average, two seconds. Not much of a difference, right?

However, once those seconds add up, it can take over 6,000 seconds more to scan all the items for the day than it does to scan the location. We also can’t forget the time it takes to enter quantity; with a slow WMS, this can often take longer than 4 seconds to input and enter, but for this scenario let us assume it also takes on average 2 seconds. That’s another 12,000 seconds to add to the mix at the end of the day. Just adding up those seconds alone, your pickers end up spending 30,000 seconds per day on these tasks alone — over 8 hours!

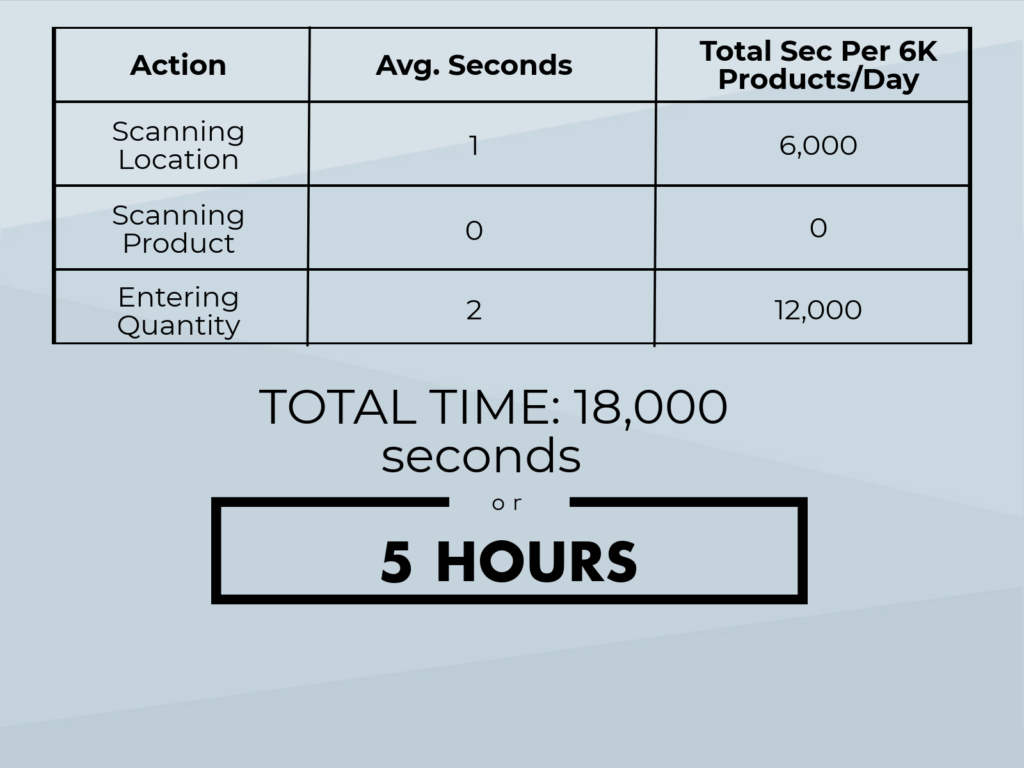

Now, let’s bring in an advanced WMS which is developed specifically for B2B and B2C fulfillment. Unlike other WMS’s, they allow you to change and modify the page with these processes. This means that you can configure your WMS to give you the products within a location once you have scanned it, thus saving your picker the 2 seconds per product needed to scan the item in. This can save over 12,000 seconds within a regular day, which can end up saving your pickers 3 hours!

As you can see, even 1 second can matter a lot in warehouse logistics. However, with the right WMS, you will always have peace of mind by knowing that your time as well as your employee’s time is never wasted. Logiwa is optimized for saving time in the warehouse and saving you money, too!

Releate Terms

WMS Integration

If you’re thinking of integrating into a new WMS warehouse management system & wonder about impacts, this is a must-read.

WMS Software for Ecommerce

Online shopping and ecommerce continue to grow. But is your warehouse management system ready to meet the ever-growing demand?

FedEx Drop-Off

With FedEx Drop-off, you can easily pick up and drop off packages near you. But is it really as easy as it sounds?

Eco-Friendly Packaging

Eco-friendly packaging has become increasingly prevalent to the world, as well as consumers. Learn about sustainable methods and the benefits of green packaging in this article by Logiwa.

eBay Seller Hub

eBay’s Seller Hub remains a top ecommerce site by offering centralized seller tools, data to increase profits and ease of usability. Learn how to navigate eBay’s Seller Hub in this latest article from Logiwa!

WMS vs ERP

Discover the differences between Warehouse Management System vs Enterprise Resource Planning & how you can benefit – look now!