The fulfillment industry is on the precipice of rapid transformation, driven by the challenges of an evolving global landscape and customer expectations.

In the recently released eHub Contributor Report 2024, leading figures from the world of logistics and supply chain management, including Erhan Musaoglu, CEO and founder of Logiwa, share their collective experience and lived experience to shed light on the critical challenges impacting fulfillment management and offer insights into solutions.

Here we dive into three of the key challenges discussed in the report, and share how Logiwa IO, our AI-driven fulfillment management system, helps fulfillment centers address these challenges.

Challenge: Optimizing Inventory Management

Overstocking and stockouts are two sides of the same problematic coin in inventory management. It’s well known that keeping too much inventory can tie up capital and storage space, while not having enough stock can lead to dissatisfied customers. While several strategies exist to improve supply chain agility and inventory forecasting, the experts agree that it all starts with improving visibility across your fulfillment network.

Your warehouse management system (WMS) should serve as the source of truth for how your inventory is moving. However, many of today’s WMSs lack the advanced analytics and real-time inventory management capabilities needed to provide visibility and actionable data insights.

These are both important features of Logiwa IO. Among Logiwa IO’s real-time inventory capabilities is the Available to Promise (ATP) report which shows projected inventory available for sale. This information allows businesses to keep the minimum amounts of products on-hand. The ATP report considers pending purchase orders, allocated (reserved for sales orders) inventory, and any damaged quantities, enabling businesses to keep the minimum amounts of products on-hand by anticipating customer demand and adjusting ordering for popular products.

Challenge: Delivering a positive returns experience

Returns are not only frustrating for consumers, but incredibly costly for brands and suppliers. While consumers who encounter a poor returns experience are 3X more likely to abandon the retailer, 95% of online shoppers are willing to buy again from a retailer who they experience a good returns process with.

For retailers, the cost of one return can cancel out the profits of an average of eight to 10 successful sales. So how do you keep the rate of returns as low as possible and deliver a positive consumer experience when a return does need to happen?

One way to drive a low return rate is by ensuring product accuracy and quality before an item is shipped. For fulfillment operations, this means having quality control processes not only in place but that fulfillment teams adhere to.

Within Logiwa IO, we have built quality control processes throughout the picking and packing process.

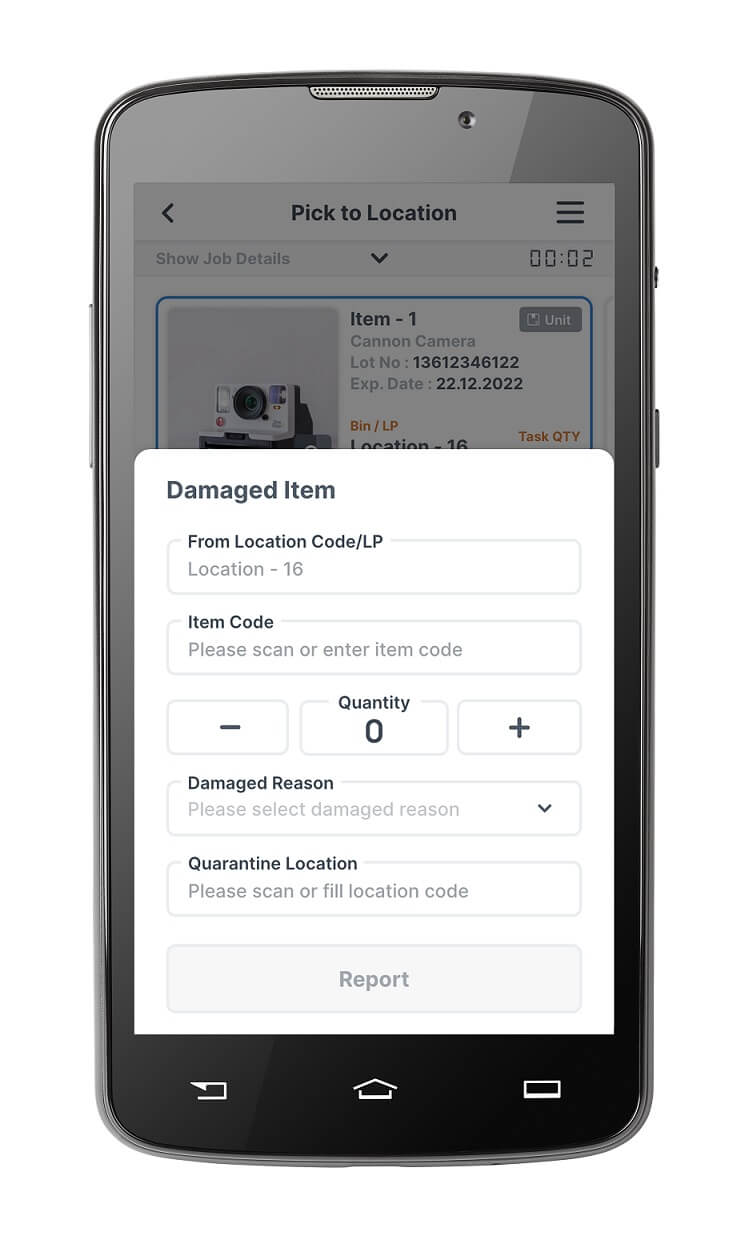

During the picking process, the Logiwa IO mobile app not only identifies the exact location an item is to be picked from but also provides an image and description of the item to verify they are in fact picking the correct item. When it comes to ensuring quality, we enable pickers to report an item as damaged, with a damage reason and transfer them to an appropriate damage location all from within the same screen.

The same checks are in place during the packing stage. The packing station interface features images, descriptions, and quantities of each item meant to be in that order as a second level confirmation before shipments are sealed and again provides the ability to report an item as damaged and assign a reason from within the same screen.

Logiwa IO’s user friendly interface makes it simple to perform operations like marking damaged items during picking.

Unlock a personalized tour of Logiwa IO

Challenge: Accessing and Utilizing Data for Better Decision Making

The importance of comprehensive data collection and analysis to drive decisions from inventory forecasting to picking and packing workflows to cartonization cannot be overstated. The application of machine learning-based AI is growing both in popularity and necessity to address the existing insufficient fulfillment data availability and analysis gap.

As Musaoglu states in the report, “AI-driven fulfillment management systems can optimize operations to cut the number of hours needed to fulfill orders by as much as 60%,” highlighting the impact using machine learning can have on fulfillment operations.

One such capability offered by Logiwa IO is AI Job Optimization. Created to optimize both picking and packing operations, AI Job Optimization considers multiple factors, including order volumes and dimensions, picking location distances, as well as cart and tote dimensions. Using these data points, the system creates optimized assignments and workflows with consideration to clients’ preferred job batch sizes and other business rules including order priority, tags and zone conditions. Resulting outputs for picking operations include providing the most efficient item picking order and job task assignments. For packing operations, optimization outputs include the identification of where bulk labels can be printed for batch pick flows, speeding up the packing process.

Additionally, Logiwa IO offers support for tote-based operations, allowing each tote to have a distinct job type. The system intelligently tracks and prints labels for each job within the respective tote.

Download the full “eHub Contributor Report 2024”

Having explored just a few of the challenges addressed in the eHub Contributor Report 2024, we encourage you to download the full report to dive into the range of challenges discussed and benefit from the strategic insights shared.

Want to learn how Logiwa IO is solving these and other high-volume fulfillment management challenges? Schedule a demo today.

Keep up with consumer demands with an agile and responsive fulfillment management system

Warehouse Management

Modern digital WMS powers a modern fulfillment experience