Modern warehouse and fulfillment management solutions include warehouse license plate (LP) tracking features to help streamline and optimize B2B operations. In this blog, we will explore the vital role of LPs in warehouse operations, as well as essential questions to ask your WMS provider to ensure your solution has the features needed to support LP operations.

Key Takeaways

- Advanced LP and pallet management features enhance B2B operations by improving inventory management, supply chain logistics, and reducing errors and delays.

- Logiwa IO supports a variety of LP types, configurable LP parameters, and advanced features for streamlining pallet operations and competitive B2B logistics.

- Essential features to look for in a solution: hierarchical LP creation, efficient LP management for inbound/outbound processes (like picking, transfers, cross-docking), and LP-based billing.

Contents

- The Vital Role of License Plating in B2B Fulfillment

- Why You Need Robust Warehouse License Plate Management

- LP Functionalities: 9 Questions to Ask Your WMS Provider

- Do you provide functionality for pallet operations?

- What LP Types does your solution support?

- Does your solution allow users to configure LP parameters?

- Does your solution support hierarchical LPs?

- How does your solution handle inbound pallet operations?

- Can your solution group order LPs for outbound operations and shipping?

- Does your solution support transfers?

- Does your solution support cross-docking?

- Can your solution support 3PL billing for LPs?

- FAQs Related to License Plating and LP Types

The Vital Role of License Plating in B2B Fulfillment

In warehousing, license plates (LPs) offer a way to easily identify pallets and other groups of products and materials. They aid significantly in the B2B process by enabling efficient tracking, picking, transferring, receiving, and shipping operations in the warehouse. With LPs, users can track many items with a single scan, rather than having to scan individual items.

This streamlined approach not only saves time but also reduces the likelihood of errors, ensuring that inventory data is accurate and up-to-date. In a fast-paced B2B environment, where large quantities of goods are constantly moving in and out of facilities, the ability to quickly and accurately manage inventory through LPs is critical for maintaining customer satisfaction and operational efficiency.

Why You Need Robust Warehouse License Plate Management

Without the ability to properly track and manage LPs, your business could face a wide variety of complications—from inaccurate inventory data to costly shipping mistakes.

WMS that cannot fully support LP operations make tracking and locating inventory a time-consuming task and increase the likelihood of errors and delays. Additionally, a system incapable of adequate pallet management can result in poor space utilization in the warehouse. This limits your ability to track and manage pallets effectively, which leads to cluttered and disorganized storage areas.

In addition to better tracking and storage operations, advanced LP management tools ensure you can:

- Optimize the processing of pallet items. This can include things like consolidating different order items for better space utilization, shipping logistics, and cost-savings, or splitting pallets contents for sending items to different destinations.

- Support more effective integrations. Seamlessly exchange valuable data with other logistics and supply chain management tools to maintain real-time visibility and control over your entire inventory and order management process.

- Enhance operational accuracy and reporting. By providing detailed insights into pallet movements, storage durations, and handling processes, your business can make more informed decisions about inventory management, warehouse operations, and overall supply chain efficiency.

- Reduce labor costs. Efficient LP management minimizes the need for manual checks and rechecks, allowing staff to focus on more productive tasks, thereby reducing labor hours and costs.

- Improve inventory turnover. By having a better handle on inventory through LP management, businesses can reduce overstocking and understocking, leading to more efficient inventory turnover and reduced holding costs.

- Enhance customer satisfaction. Accurate and timely order fulfillment, made possible by effective LP management, leads to higher customer satisfaction and repeat business.

- Facilitate better compliance and safety. Proper LP tracking helps in adhering to regulatory compliance requirements and ensures safer handling and storage of goods, reducing the risk of accidents and associated costs.

Related Content: Warehouse Automation for Inbound & Outbound Processes

License Plate Functionalities: 9 Questions to Ask Your WMS Provider

When assessing a WMS or FMS, it’s not just about checking the box for pallet support. It’s about understanding the depth and breadth of the system’s LP functionalities and how they align with your specific B2B operational needs. This is key to ensuring the system can handle the complexities of your warehouse operations and contribute to the overall efficiency and effectiveness of your supply chain.

Let’s talk through the key LP questions to ask when evaluating fulfillment solutions for your B2B operations, as well as how Logiwa IO addresses those needs.

1. Do you provide functionality for pallet operations?

It may seem obvious, but clarifying that a WMS or Fulfillment Management System (FMS) supports pallet operations is the first question you should ask when evaluating a solution. Not all platforms provide B2B features. Make sure you verify the solution supports LP operations and the level of functionality you need.

2. What LP Types does your solution support?

Ask what types of LPs can be defined, as well as the types of data that can be contained within each LP. This gives you instant insight into how adaptable and robust a solution’s LP capabilities are. Think about specific use-cases and how LPs will be used to support your unique operational needs.

Logiwa supports pallets, product cartons, boxes, ocean freight containers, and any other large containers your operation may use. Shipping labels with tracking numbers can even be considered license plate numbers, because they define a unique package and help support tracking.

Logiwa IO optimizes pallet operations using:

- LP Types: Refers to various LPs that can be defined in the system (example: Euro Pallet)

- LP Numbers/LPN: Numbers that can be created and assigned to each LP type.

In our system, pallets and shipping boxes can be created as LP types and those LPs can be assigned with a unique set of LP numbers. That way, each LP can be easily identified. Having a variety of LP types in your warehouse helps you to monitor and track processes, such as the movement of your products, both inside and outside your warehouse.

3. Does your solution allow users to configure LP parameters?

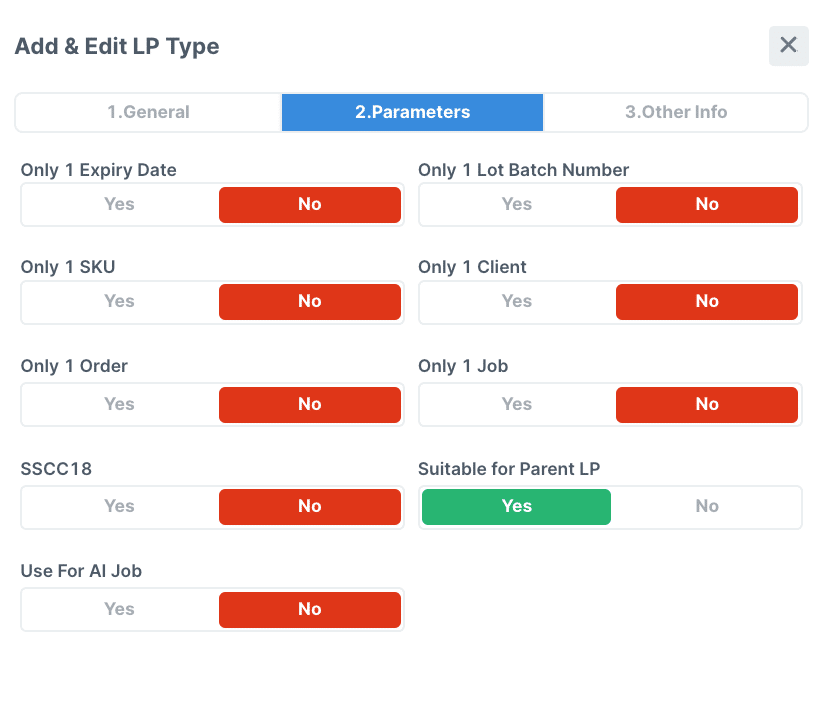

The ability to configure LPs ensures you have total control over pallet operations. This includes the ability to better organize pallets as well as the items on them. For example, ask if the solution allows users to set parameters such as the ability to allow only one Lot number or multiple on a pallet or the ability to keep 1 or multiple orders on a pallet. These parameters provide flexibility and help you prevent errors in the operation.

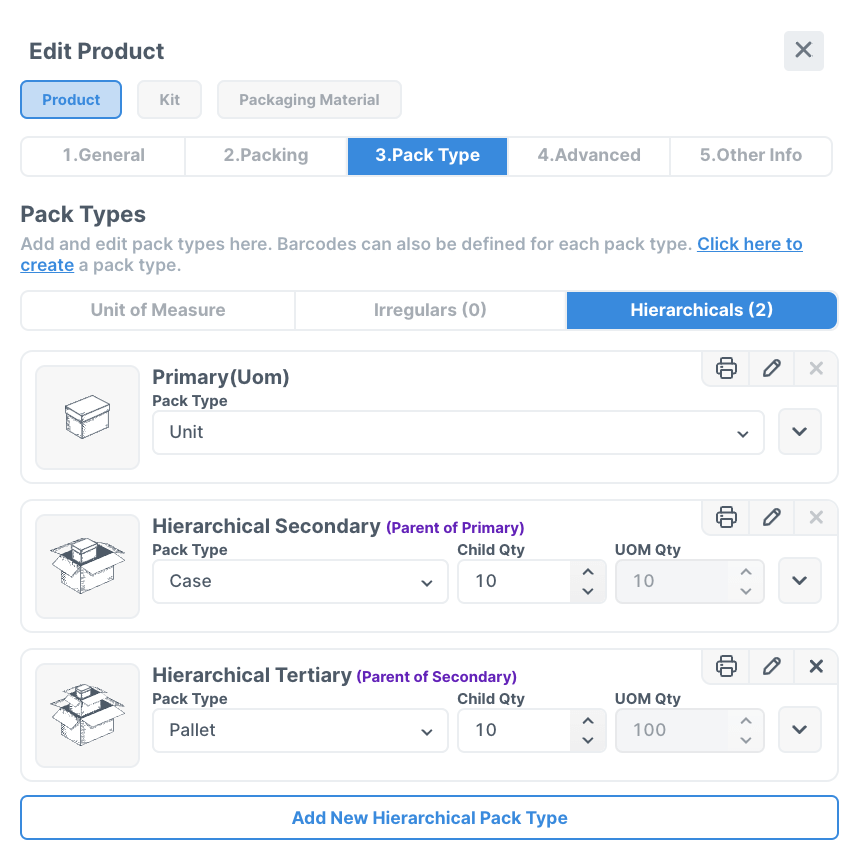

Not only does Logiwa IO support different types of LPs and the aforementioned parameters, but users can also set up multiple pack types and customize workflows to enhance inventory management and outbound operations. For example, if an order comes in for 10 units of a specific SKU, Logiwa IO knows to allocate a full case or pallet to save time.

Logiwa IO’s user-centric approach also ensures users can build their algorithms around pallets using LP data. More specifically, users can use LP types as conditions for putaway and allocation algorithms. This allows users to set unique workflows with LP-type operations.

Unlock a personalized tour of Logiwa IO

4. Does your solution support hierarchical LPs?

For most operations, it’s not enough to simply receive and identify a pallet. Warehouse operators need to be able to break down the contents of LPs in order to run efficient operations, including generating the appropriate labels and documentation. If your operation utilizes Fulfillment By Amazon (FBA) services, this is even more important.

Ask your WMS provider if they are able to support hierarchical LP operations. In other words, ask if you can set up multiple layers of visibility, allowing you to see where pallets are and exactly what is on them. An example of this is Logiwa IO’s “Parent LP” functionality. This type of LP feature is a game-changer for B2B operations, especially those managing Retail Compliance and Amazon FBA operations. It allows each box on a pallet to have a unique label, so users can build custom parent-child hierarchies.

Logiwa IO allows users to build a hierarchy between LP types using our “Parent LP” feature. This means that pallets can be set up as a “Parent LP” while pallet contents (e.g. cartons) can be labeled as “Child LP.” This not only allows you to better organize your operations; it allows you to break down the content of pallets for labels with maximum accuracy and convenience. It can also make replenishment processes and AI- driven jobs even more efficient.

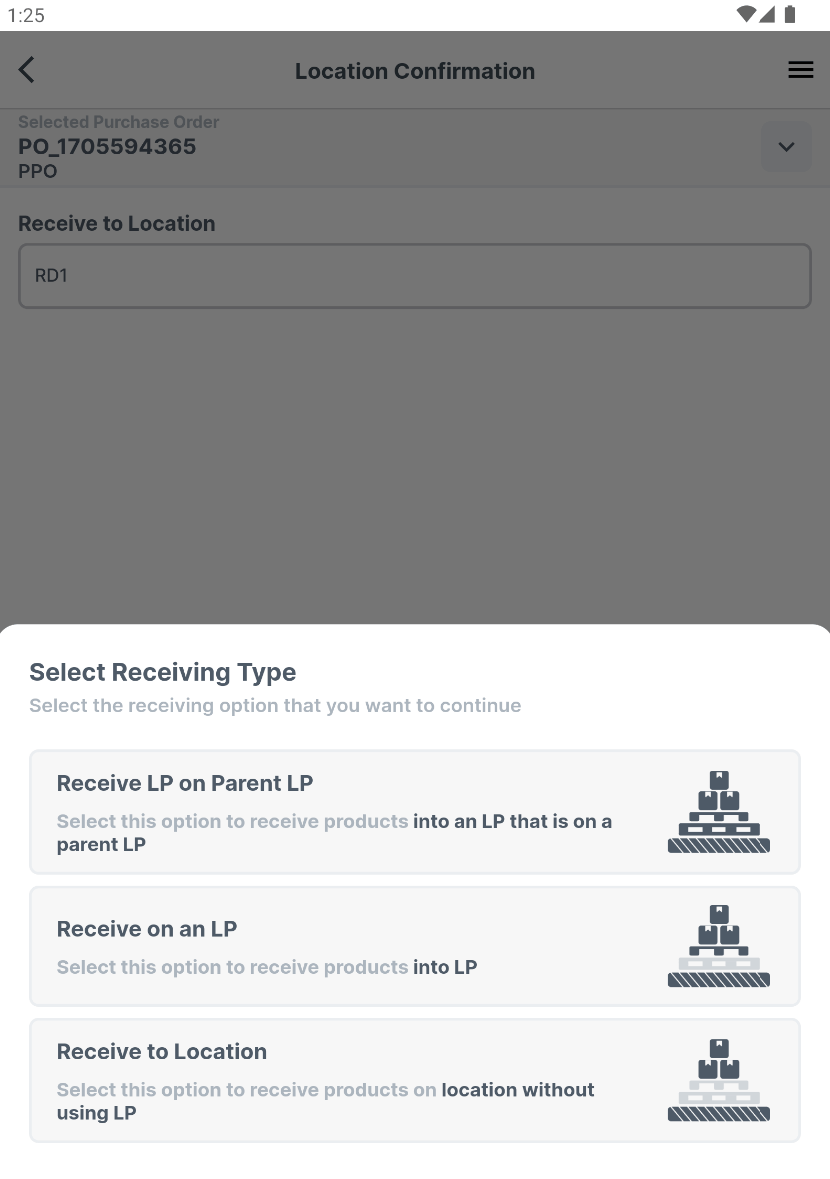

5. How does your solution handle inbound pallet operations?

When it comes to receiving pallets, it’s crucial your solution can handle the various scenarios that often occur with B2B logistics. This includes addressing LP complications that arise when pallets arrive from your vendors that fail to meet Retailer Compliance standards.

Consider asking if the solution has a way to address pallets that do not contain full quantities of stock? What about pallets that contain multiple SKUs? Your solution needs to be able categorize pallets into different categories as receipts come in and address all possible scenarios with ease.

Logiwa IO makes it easy to receive and label pallets based on different scenarios:

- Floor Loaded Pallets: No pallets/just boxes in a truck

- Mixed Pallets: Palletized goods/pallets that contain multiple boxes of SKUs

- Pure Pallets: Pallets that are set up as they should be

Moreover, Logiwa’s FMS allows both vendors and warehouses to specify on the PO/ASN which SKUs will be on which pallets. Using order receipts, operators can receive pallets or Parent Pallets and automatically generate labels using our system. Users can also configure them to include whatever data is needed. This helps warehouse staff sort during receiving, and enforce single SKU pallets to simplify operations.

6. Can your solution group order LPs for outbound operations and shipping?

When it comes to fulfilling B2B orders, it’s crucial to be able to identify the appropriate pallets with each order. This ensures you are able to create effective shipment plans and prioritize shipments appropriately and staging items for effective pick-ups.

Ensure the WMS solution has a strong process for automating this process, as well as grouping orders, generating labels, and orchestrating outbound activities. Logiwa IO aids this process by allowing for layering LP groups. Here’s a quick walk-through of our process:

- Order or group of orders is sent to the warehouse with an expected pickup date.

- Logiwa IO groups these orders together into a Shipment Plan.

- Users can track which pallets were allocated or built for each order in the planned shipment.

- Multiple operators can work together and pick the different pallets for the order.

- Once picked, Logiwa IO will allow the operator to Load the pallet to a Dock Door.

Moreover, our solution allows users to generate all the necessary documents and labels needed to complete the outbound process using the existing pallet and LP data. This can include:

- Generating Carton Labels for the cases on the pallet.

- Generating Pallet Labels for the outbound pallet.

- Generating BOL documentation for the LTL Carriers.

7. Does your solution support transfers?

Pallet transfers are a common occurrence in warehouse operations, necessitated by various needs such as optimizing storage space, preparing for shipments, or reorganizing inventory for better accessibility. When a WMS seamlessly supports these transfers, it ensures that inventory data remains accurate and up-to-date, minimizing the risk of misplaced items and inventory discrepancies.

Make sure your WMS or FMS solution supports pallet transfers or License Plate (LP) transfers to ensure operational flexibility and efficiency. This capability also allows for more dynamic and responsive warehouse operations, enabling you to quickly adapt to changes in demand, streamline the picking process, and reduce unnecessary movement and handling.

Whether you are executing directed putaway, transferring full pallets to new locations within your warehouse, or overseeing replenishment operations—Logiwa IO makes it easy to direct and streamline pallet transfers across tiers of LPs. For example, our flexible inventory management and LP functionalities allow you to replenish a picking location by picking a certain LP.

8. Does your solution support cross-docking?

Cross-docking allows for the direct transfer of goods from incoming to outgoing transportation without the need for intermediate storage, leveraging LP technology to track and manage these movements seamlessly. This process minimizes the time goods spend in the warehouse, significantly reducing storage space requirements and handling costs.

By supporting cross-docking, you can expedite the flow of goods through your warehouse, improve inventory turnover, and reduce lead times, which is crucial for meeting customer expectations for prompt delivery. If the inbound order is a crossdock, Logiwa IO can be configured to have the operator just scan the existing pallet label and the system will mark the entire pallet as received (based on the PO/ASN) before directing the transfer to the appropriate docking area.

9. Can your solution support 3PL billing for LPs?

3PL solutions should be able to automatically track and bill for the storage, handling, and transportation of goods based on detailed pallet and LP data. By accurately capturing the movement and storage time of each pallet or LP, WMS solutions enable 3PL providers to implement precise and transparent billing practices, tailored to the specific services utilized by their clients.

Warehouses can capture LP operations with the Logiwa IO’s billing functionality and charge their clients accordingly for receiving, picking, packing, shipping, and value-adding operations.

Related Content: Material Handling 101: How to Keep Your Warehouse Productive With Warehouse Inventory Management Software

Logiwa IO Makes LP Operations Easy

Solutions like Logiwa IO were built based on user feedback—ensuring key functionalities for real-life use cases are addressed. This includes a variety of B2B features like advanced LP capabilities.

In today’s fast-paced logistics world, Logiwa IO brings revolutionary efficiency to LP operations, transforming B2B processes. Experience the ease and speed of tracking entire containers with a single scan, eliminating the need to scan individual items. From our Parent LP feature to the ability to use LPs for AI-driven job allocations and replenishment processes—our FMS significantly enhances operational speed and accuracy.

FAQs Related to License Plate Number Warehouse Management

What is an LP, or License Plate Number (LPN), in warehousing?

License plates (LPs) and LP types are both used to refer to the specific containers where inventory is stored. In addition to their storage function, LPs help with tracking, transferring, receiving and shipping operations in your warehouse, as you can track them with a single scanning action rather than scanning all items on the LP individually.

Can a WMS handle multiple LP types within the same warehouse?

Yes, a robust WMS or Fulfillment Management System (FMS) can manage various LP types simultaneously, ensuring seamless tracking and organization of different inventory items across the warehouse.

Power up your fulfillment operations with AI-optimized automations, user-centric design, and true cloud infrastructure.

Warehouse Management

Modern digital WMS powers a modern fulfillment experience