During the first half of 2020, year-over-year sales growth for U.S. online retailers tripled compared to the first six months of 2019. It’s not unheard of for some warehouses to have increased shipping up to 12 times higher compared to pre-2020 levels. While the business growth is awesome, today’s reality presents new challenges to warehouses that need to ship more orders on time to keep up with demand.

These new opportunities make it more important than ever to improve warehouse efficiency and decrease time spent on getting goods to customers. That’s why eCommerce success today depends largely on two key metrics: order lead time and order cycle time—and there are specific ways to minimize both.

In this article, we’ll first look at the characteristics of order fulfillment lead time and order cycle time and the importance of having short shipping lead times. Then, we’ll break down real-world methods in which you can improve these parameters for improved business outcomes.

Contents

How Is Order Lead Time Calculated? How Is Order Cycle Time Calculated?

Order lead time and order cycle time are two important warehouse KPIs that often get confused with each other. Order cycle time is the average time between any two orders shipped. For example, Order cycle time formula, if your company ships 1000 orders in 8 hours, the order cycle time is (8 hours * 60 min * 60 sec) / 1000 = 28.8 secs/order. This means you ship orders at an order cycle time of every 28.8 secs.

Meanwhile, order lead time is the average length of time that passes between a customer placing an order and the order is shipped. Order fulfillment lead time is calculated like this:

(time order is shipped from the warehouse – time order is placed by the customer) / (total number of orders shipped)

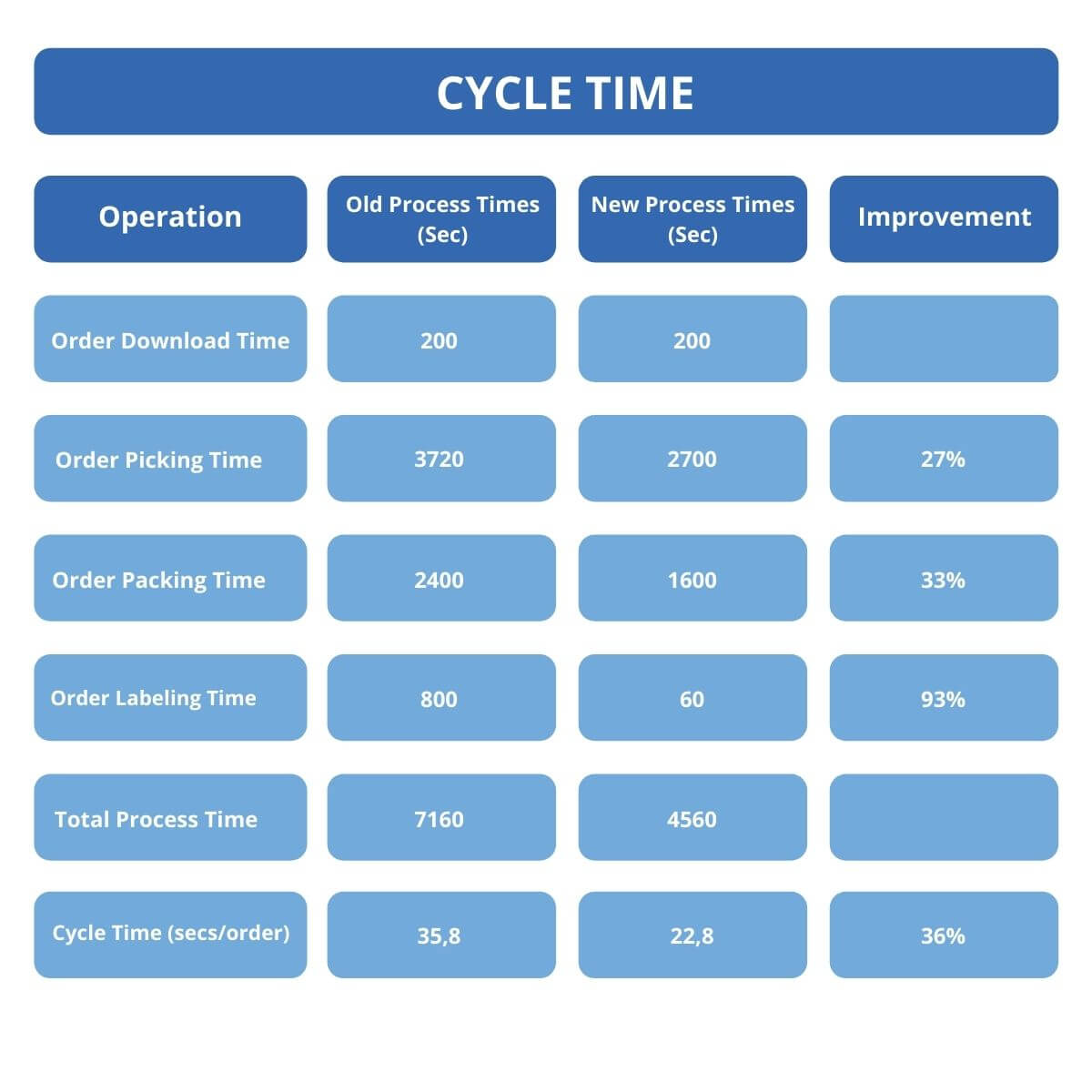

The below table shows statistics for a Logiwa customer’s cycle time improvement.

The average Logiwa customer improves order cycle time by 30% within 3 months after implementing Logiwa WMS.

Order Lead Time Components

Lead time can also be broken down into different parts. For example, between the date the order is placed to the date of delivery, several events can occur. The customer’s preferred order lead time might not exactly match the quoted order lead time. Next the confirmed order lead time might differ from the quoted order lead time. Finally, the actual order lead time might also vary due to unforeseen delays.

For this reason, many companies might offer a range of dates for order delivery as well as order tracking for the customer to be able to follow the package’s progress.

Reducing Order Lead Time

The ‘Why’ of Order Lead Time Reduction

In this day and age of instant gratification, on time, fast delivery is everything. In fact, one study showed that 87% of shoppers determine that order delivery cycle time is a key factor in whether to shop with an eCommerce brand again.

The study also found that 67% of online shoppers are willing to pay more money to get same-day delivery if they need the package by a deadline, such as a birthday. Also, 47% of those surveyed would pay more for same-day delivery simply because they want their package sooner.

This highlights two real business benefits to lead time control and reduction:

- Improves customer satisfaction & loyalty

- Faster delivery provides for an upsell opportunity

How To Optimize A Supply Chain’s Order Lead Time

Before we learn how to improve your internal warehouse order lead time, it’s also important to consider your supply chain order lead time. No matter how efficient your warehouse picking and packing system is, if you don’t have optimal supply chains in place, both order lead time and order cycle time will suffer.

To minimize supply chain order fulfillment lead time, some areas you can focus on include:

- Analyze your warehouse flow in detail. Let’s say the movement of your goods relies on FIFO (first in first out) methodology, and there’s a delay in moving inventory to the shelves. Maybe a stack of boxes has accumulated at your receiving dock. If another delivery arrives and gets piled on top of the first stack, then your FIFO rules will be broken since the latest delivery must be cleared first.

- Revise your contingency plans. How will you handle unexpected, late, or canceled deliveries

- Reach solid supplier agreements. Long-term, loyal relationships are a supply chain priority. This enables you to standardize processes and fine-tune supply time schedules.

Work with your suppliers to optimize key supply chain components (e.g. manufacturing, transport, warehouse processing, etc.).

How to Reduce Order Lead Time

Now let’s take a look at some specific strategies to reduce your order lead time to improve workflow and customer satisfaction.

Minimize the Walking Path

It might seem like common sense for warehouse pickers to know how to get from point A to point B. However, for larger warehouses with a variety of SKUs, picker pathways can become highly complex. This can result in pickers walking extra miles which negatively impacts order fulfillment lead time and also increases worker fatigue and injury risk.

Some ways to minimize picking walking paths include warehouse layout optimization and picking up various items along the way. Still, even these strategies have their limitations as the number and variety of orders increases. In fact, several advanced strategies and computer algorithms are now used by companies to optimize warehouse walking paths.

An average picker walks 6-8 miles a day if you don’t optimize the walking path. Logiwa can decrease this number by at least 26%.

Group Different Order Profiles Properly

Another way to reduce order lead time is to create different groups for single item orders, identical item orders, and multi-item orders. For each group type, you can apply a separate operation which reduces the time to pick and pack the orders. For example:

- Single Item Orders: Batch pick and pack the orders by scanning the item code only.

- Identical Item Orders: Group the orders having the same SKU together, batch pick them and batch print the carrier labels.

- Multi-Item Orders: Apply cluster-based batch picking for various quantities of different SKUs.

Limit Picking Batch Size

Don’t fall into the temptation to generate super long pick lists thinking it will save time. First of all, large batches take more time to pick. As a rule of thumb, the total batch duration should not be over one hour. Plus, the room for error grows with batch size. Also, it works better if you have separate batches for large and small items.

Directed Putaway

When a new supply of goods arrives, workers place the stock on storage shelves (putaway). The most logical putaway locates the goods so they can easily be located and shipped off quickly. Where exactly a good winds up when it enters a warehouse impacts how efficient the warehouse picking and packing processes will be.

For more efficient picking, you can revise and optimize your putaway rules. For example, you can put not similar products into the same location, so that the picker finds the correct SKU easily. You can also put popular, fast-moving products into easier to reach locations.

Directed putaway takes this one step further by using warehouse software (WMS) which directs workers exactly to where incoming inventory should go. This makes everything more organized, and items are easier to find later.

Increase your picking efficiency by 30% with a proper Putaway process in place.

Minimize Picking Errors

Minimizing errors during the picking process is essential. If an incorrect item is picked, this can easily double the picking time component of order lead time.

One way to reduce picking errors is by keeping track of mistakes. This allows you to systematically identify problem spots and make corrections. Plus, all items should be clearly marked, and similar items or packaging should have an easy way to differentiate them, such as by color-coding. Some larger warehouses might even put similar items far apart from each other to minimize confusion.

Another strategy is to keep the pick lists simple and orderly. The grouping strategy we mentioned earlier can help with this. Plus, don’t let your pick lists get too long as this can also cause confusion or missed items. In a similar manner, SKUs that all look alike should be avoided. Make things as easy as possible to distinguish.

Smart Replenishment

A proper stock replenishment process in place helps ensure you never have stock-outs on the picking locations. A demand-based replenishment algorithm constantly checks orders to calculate replenishment quantities. A solid replenishment process includes:

- Maintaining real-time inventory data

- Establishing end-to-end visibility over your entire supply chain

- Collaborating with salespeople, inventory managers, long-term customers, and suppliers to create demand forecasts and replenish inventory

- Identifying new/closed competitors, seasonal demand, and supplier issues

- Creating a contingency plan if your demand forecast fails

- Establishing stock replenishment rules

Reducing Order Cycle Time

When to Reduce Order Cycle Time

You need to find ways to reduce the order cycle time especially when you are experiencing high volume increases. In many cases, order cycle time variables overlap with order fulfillment lead time factors.

Methods to Reduce Order Cycle Time

Improve Order Picking Processes

As we mentioned earlier, shorter, well-organized pathways and optimized warehouse design are critical to minimizing picking time and maintaining worker health. Your overall order picking model can also make a big impact. Some examples are:

- Pick to Order – Employee gets an order list and goes through the warehouse picking items one by one. This might work for very small warehouses, but it doesn’t scale well.

- Batch Picking – Assembling batches of the same item from different orders to be picked at once. This works for companies with a wide range of SKUs, however, the items in the batches must be separated into each order later.

- Wave Picking – It’s like batch picking, but workers go out in designated waves throughout the day. This works best when using WMS.

- Zone Picking is an enhanced version of batch picking. Workers are assigned to specific zones, and order cartons move through those areas picking up items selected by workers in each zone.

- Cluster Picking – Using multi-tote or multi-bin contraptions, workers will pick items for multiple orders at the same time.

Improve Label Generation Processes

Any delay in label generation will increase order cycle time. Overall, label generation depends on the following factors:

- Address verification. Any mistake will lead to large order cycle time delays.

- Bulk label printing. Large volume order processing requires some specific methods for order picking and packing. Orders get classified based on item count and variation of the orders. Printing jobs can be divided into identical, single, and multiple items.

- Shipping rate shopping. Label generation can be directly linked to shipping costs. Automated methods exist to land the best rates.

- Order packing. This is a key process for fast order processing and preparing for shipment. In high-volume order processing warehouses, having printing labels at the packing stations saves time and reduces errors.

Unlock a personalized tour of Logiwa IO

More Packing Stations Vs. More Pickers

The key here is to find the bottleneck within your operation. You definitely want to avoid having too many pickers compared to what your packing stations can handle. This will delay order packing and increase order cycle time. On the other hand, it’s not efficient to have an excess of packing stations for relatively few pickers. You’ll waste resources while packers wait and do nothing. You need to test and track results to find the best combination.

Optimize Order Lead Time & Order Cycle Time to Improve Business Outcomes

Order lead time and order cycle time are closely related, but they measure different things. If you take the time to improve these metrics, you can substantially increase your warehouse efficiency. In the end, it cuts costs, improves customer experience, reduces risk, and boosts your bottom line.

Cloud Fulfillment Network Software For Consistent Fulfillment Success

Warehouse Management

Modern WMS cloud fulfillment powers a modern experience

Inventory Management

Improve your inventory across your supply chain.