The Key to Managing Seasonal Employees

Your customers’ expectations of your online store have risen exponentially in the past few years.

Not only do they expect their order within days of placing it, but you’re also implementing personalization for each shipment to stand out from your competitors. It’s not enough to deliver the correct product to the customer within a two-week delivery window.

Modern technology has enhanced the online sales experience, and long standing companies are now struggling to keep up with demand.

Contents

BONUS: Download our Warehouse Labor Planning Template to get the most accurate labor forecast.

Why You Need Seasonal Employees: Sales Soar During the Holidays

In 2018, US consumers spent a record-breaking $850 billion dollars between Thanksgiving and Christmas. That’s a 5% jump from the previous year, says McKinsey. This extreme growth is mostly due to the exponential increase in online holiday sales, which was up 19% from 2017 and is only expected to increase throughout the upcoming years.

Customers want personalization – they want to feel like their order was picked packed, and delivered just for them. The marketing and branding team can work months on the perfect customer experience through their online platform. However, it serves no purpose if the warehouse isn’t equipped with the correct tools and training to properly complement this thoroughly crafted online experience.

Whether you are focusing on quick fulfillment and delivery times, using Amazon as a standard, or focusing on customization of the product, such as subscription box fulfillment, high accuracy and precision are essential for a successful order fulfillment process.

With temporary workers and increased volume, a learning curve is inevitable. Your secret weapon? Your warehouse software. That’s the key to shortening the learning curve and maintaining high order fulfillment performance.

Not only will this be useful for onboarding the seasonal employees, but it will provide constant guidance and process validation throughout your inbound and outbound operations. Additionally, using a WMS post-holiday season will help you manage returns as well as inventory corrections within the warehouse.

Holiday Season Labor Planning

Initially, when hiring your temporary workers, you need to determine the correct labor planning that will be needed. On average, labor costs makeup 60% of the overall warehouse costs.

If you overestimate the number of temporary workers needed during the upcoming peak season, you will have to either eat the cost, or send workers home early. Sending workers home early doesn’t cultivate a positive company culture. Many people rely on working 20 hours (part time) or 40 hours every week (full time), and sending them home without pay will create anxiety and resentment throughout your team that will be difficult to mend.

On the other hand, underestimating the amount of labor you will need for this upcoming peak season will leave you unable to meet your SLA (Service- Level Agreement)- which is critical during the holiday season.

Make a Whole Warehouse Walkthrough Part of Your Training

About a week or two before your peak season begins, start bringing in your temporary workers so you can begin the training sessions. If you have a detail oriented packing process, you should bring your temporary workers into the warehouse a week earlier than the other areas, due to the necessary training.

We recommend that you bring in 20% more temporary employees to train than you think you’ll need. This allows a cushion for the temporary workers who aren’t a good fit or who quit.

Using a WMS software eases the difficulty of training temporary warehouse associates. It may seem counterintuitive – not only are they learning a new operational process, but also a new software? But, in actuality, if you are using the correct or Best WMS software for your business, it will provide a guided walkthrough of the process, taking your associates through the necessary steps.

Your software can give automatic verification to new associates when they follow the correct process and scanning the correct locations and products. It is difficult to make mistakes when you have a system checking your every move and stopping you when something is not correct.

Before you can learn a system – any system- you need to understand what you are trying to achieve and why. We recommend that you walk through the business goals and overall customer experience your company strives for. Once the temporary associates have an idea of your company culture and expectations, you can move on to showing them the physical operations within the warehouse.

We recommend keeping these training group sizes small, ten employees or less. The smaller the group, the easier it is to engage every associate and to ensure there is no confusion during the training.

Creating an intimate, safe learning environment is key to a quick onboarding. Don’t dive into the nitty gritty details of the operations just yet – it might overwhelm them and cause them to shut down if they still don’t understand the entire process. The point of this initial warehouse walkthrough is to familiarize them with the physical process. To understand the life of an item in your warehouse- from being received, all the way until it is packed and on its way to the customer.

Create a story for these associates, as if you are setting the scene for a movie – don’t over complicate it. Keep it simple and engaging.

Specific Area Walkthrough

Once they have a general understanding of the entire warehouse operations, it’s time to split them into small groups based on their designated role (picker, packer, returns associate, etc). Since temporary workers require a quick onboarding and have a low retention rate, we recommend that these temporary associates are only assigned one warehouse role.

If you wish to fluctuate your workforce so you can have a more balanced workflow, we recommend that you train your existing full time employees in the other areas so they can shift between operational processes if need be during the peak season.

You want to minimize the amount of specialization that the temporary workers need to learn. You can then create specific temporary employee user roles within your WMS to mitigate possible errors made on software functions they do not know how to use. You can simply limit their screen capabilities to just their core functions needed to perform their task.

WMS Classroom Training

Once the seasonal employees have been assigned a warehouse role and have seen the physical operational process of that role, it is time to train them on the software. It is important that they see the physical process before learning the system, as they will now be able to envision the process and connect the dots while learning the software.

Since these workers are focused on one role only, training them on the WMS system is fairly straightforward. It’s important to conduct training in small groups, so they can be interactive.

Spend 30-60 minutes walking through the WMS and basic processes in a classroom setting.

For example, if they are a packer, walk them through the steps on how to pack a single unit order, a multi-unit order, an order with a gift message, etc within your WMS. Make sure you refer to the physical process often, so they can continue the ‘movie’ of this process throughout the training.

Live Training – Core Functions

Once they have learned the systemic process for the core scenarios they will encounter 80% of the time, go out to the warehouse and continue the systemic training in conjunction to the physical process. You can have them working with real inventory and orders if you feel comfortable, or you can create test data if you would prefer.

If you choose to use test data, make sure that you create a simulation as close to the live process as possible. If you are using test locations, print out the barcodes and fixate them on a rack to simulate the real warehouse environment.

Note, some areas in the warehouse may have a longer onboarding time due to the detailed process. If your business pays extreme care and attention to the packing details of each order, then you may want to consider beginning the packers training before the rest of the temporary workers.

Exceptions Training

After they feel comfortable with the core functions of their role, it is time to introduce exceptions. Walk through possible scenarios that may occur, such as a shortage at the pack station, or an item that arrives to the pack station as damaged. It’s a good idea to keep the exceptions to a minimum, and to let them know they should consult their supervisor with any exceptions case they don’t know how to handle.

Holiday Season

By the time your peak season has begun, your seasonal workers will be fully ramped up and trained. The WMS will act as a walkthrough guide for the seasonal employees. The system will walk them through the next steps, prompting them to scan the correct item or location, and giving back an error if they missed a step or scanned the incorrect location or item.

You can also use your WMS system to track employee productivity during the peak season, which will help you incentivize your workers during these stressful and busy weeks. You can use KPI tracking within your WMS to recognize which employees may need additional training or assistance.

You can use reports within your WMS to identify which user performed a specific function or handled a specific order. Your WMS can be viewed as a teaching assistant. It helps guide the employees through the process, giving hints and instructions on the next steps.

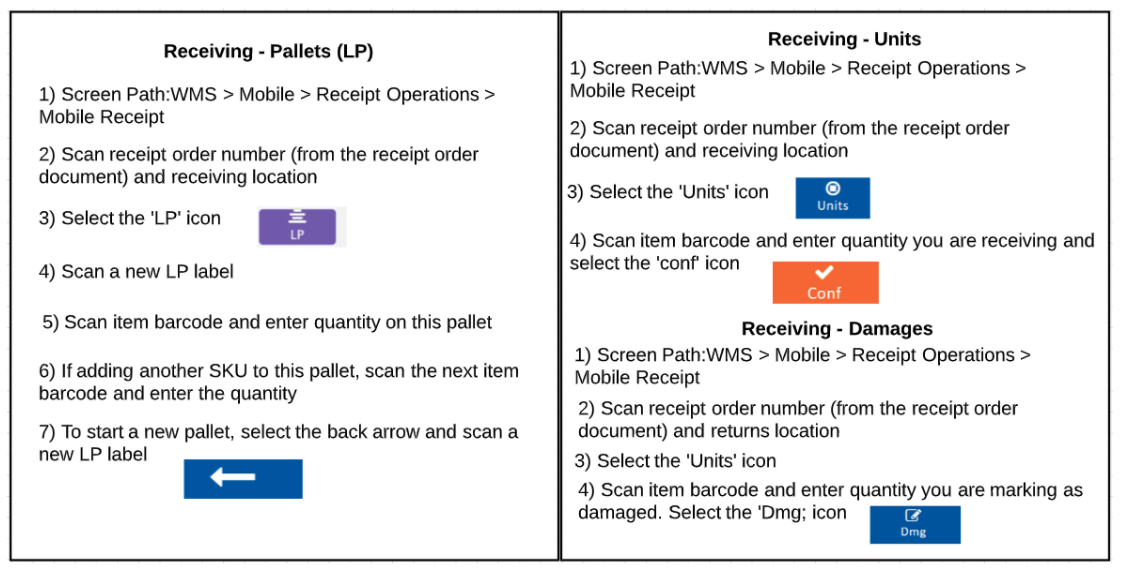

Using a WMS takes the stress off of the employees- they don’t need to memorize the processes, but simply follow the instructions on the software. Your employee will need to remember specific things, like which screen to go to for specific functions. You can utilize ‘cheat sheets’ for this type of information, something small enough that will fit in their pocket and is specific to their roles. See below for an example of a cheat sheet:

Post-Holiday Recovery

We recommend that you keep some of your temporary employees past the Holiday season due to an increased influx of returns, as well as rectifying any inventory discrepancies that occurred during the Holiday season.

Inventory Audit

We recommend inventory audits after any spike in volume in a warehouse. Although WMS utilization increases inventory accuracy to up to 100%, there are still errors made especially when bringing in temporary employees. It is best practice to perform an inventory count on every location after the holiday season.

You can use a WMS to assist in this critical process by assigning specific inventory tasks to your employees and either updating the inventory during the inventory count process or flagging this location as a discrepancy for the supervisor or team lead to verify.

Unlock a personalized tour of Logiwa IO

Returns Management

It is also critical that your warehouse is setup to manage returns after the holiday season has passed. In a recent study, 86% of shoppers stated that an easy returns policy is a main factor when deciding what site to buy from.

About 23% of eCommerce holiday sales are projected to be returned to the warehouse. Finding a WMS that allows proper tracking and managing of returns will become critical in Q1. You can properly label and identify items as damaged, even take pictures of the returned item(s). Or, if there is no quality issue, you can simply place the item back into inventory. Logging this information will not only allow you to keep track of damaged returns, but also gives you historical reporting for future holiday seasons.

You can see which items were returned the most and what the reasons were- maybe it was due to bad packaging of fragile items, meaning you need to add more packing dunnage in the future. If you have a lot of orders being returned for ‘incorrect item’, you can double check the physical warehouse location to ensure the correct product is in the location.

Not only does a WMS offer 100% inventory accuracy, but it eases the pressure and anxiety of having to quickly onboard temporary employees during the peak seasons.

Optimize your warehouse while increasing your profit.

3PL

Cloud 3PL software for high-volume fulfillment excellence