In this comprehensive guide, you’ll unravel the intricacies of warehouse labor planning, specifically for picking and packing processes. The article provides insights on optimizing various types of orders, considering picking batch sizes, defining critical parameters for labor planning, and utilizing a spreadsheet template to facilitate the process.

Key Takeaways:

- Learn how to optimize single and multi-item order picking in a warehouse environment.

- Understand the essential factors to consider when deciding on picking batch size.

- Gain knowledge about critical parameters required for effective warehouse labor planning.

- Explore a user-friendly Warehouse Labor Planning spreadsheet to estimate labor time and costs.

- Learn to evaluate the estimated number of employees needed for different warehouse tasks.

Warehouse Labor Planning – A Spreadsheet Template

In this article, I will explain a simple excel template for warehouse labor planning. I will use a sample warehouse of a small retailer. Usually, the bottleneck in a retail warehouse is the picking or packing process. So, it will be better to focus on picking and packing processes in our warehouse to do warehouse capacity planning. I will also provide a link to download the excel template at the end of the article.

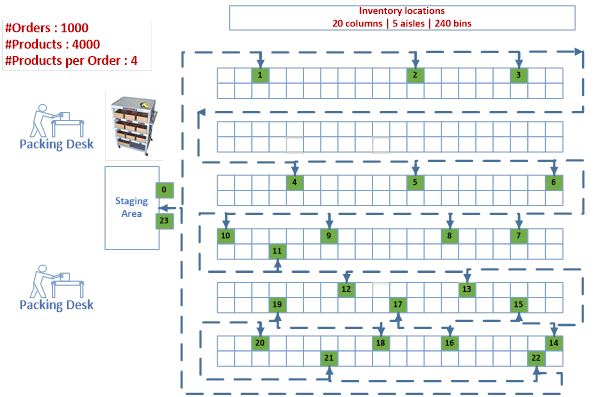

Let’s assume, we have 2 different types of orders: Single item orders and multi-item orders. Basically, single item orders are the orders which have just one SKU whereas multi-item orders have multiple quantities of the same SKU or multiple SKUs. In our sample warehouse, we will have the picking process followed by the packing process. And the shipment labels are printed during the packing process.

FREE TEMPLATE: Before you read further, download our Warehouse Labor Planning spreadsheet so you can follow along and estimate your labor time and cost.

Single Item Order Picking

Single item orders are picked in a batch of 50 orders at a time into a picking cart. The batch size may differ from one warehouse to another. The main idea behind batch picking is to reduce the number of locations for a picking trip. The order fulfillment software should consolidate the same SKUs in a batch to reduce the number of visits to the locations.

Multi-Item Order Picking

There are several options for multi-item picking. You can check various picking methods in this article. I will use cluster-based batch picking for multi-item orders. The trolleys for cluster picking include 12 bins or totes and the batch size is considered as 12. The picking batch size may differ from one warehouse to another. I will try to explain how to calculate optimum picking batch size for cluster picking and batch picking in the next articles.

3 Points to Consider When Deciding the Picking Batch Size

- Consider the size of the picking car (or container) and the products in the batch. It is better to have one picking car (container) for a batch.

- Consider the total duration to execute all the batches. The total duration for a batch should not be more than an hour.

- It is always better to create a separate batch for large and small products.

Defining the Input Parameters for Warehouse Labor Planning Spreadsheet

| Parameter | Value | Explanation | |

| Daily Shift Hours | 7 | The effective working hours for your warehouse excluding breaks. | |

| %Single-Item Orders | 15% | Percentage of orders which has 1 product. | |

| #Avg. Items per Multi-Item Order | 3 | The average number of products in an order | |

| #Single-Item Orders for a Single Batch Picking Batch | 50 | The number of single-item orders to be picked together in a single-item picking batch. | |

| #Multi-Item Orders for a Cluster Picking Batch | 12 | The number of multi-item orders to be picked together in a multi-item cluster picking batch. | |

| #Orders to be shipped daily | 500 | The daily number of all shipment orders(Single-Item and multi-item orders) | |

| #Single-Item Order Lines | 75 | The daily number of single-item orders. Formula: #Orders to be shipped daily * %Single-Item Orders | |

| #Multi-Item Order Lines | 1275 | Daily number of multi-item order lines. If an order includes 3 products, the number of order lines is 3. Formula: #Orders to be shipped daily * #Avg. Items per Multi-Item Order | |

FREE TEMPLATE: Download our Warehouse Manpower Planning Excel so you can follow along and estimate your labor time and cost.

How to Use the Warehouse Labor Planning Spreadsheet?

Order Picking Process

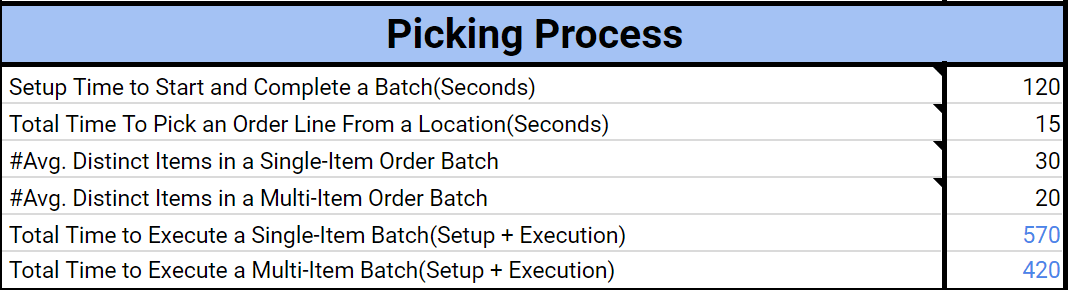

Step 1: Start with estimating an average “Setup Time” to start the next batch ( Picking the next job, picking the trolley, etc.) and to finalize the batch ( Moving the trolley to the packing station, etc. ).

Setup Time to Start and Complete a Batch(Seconds): 120

Step 2: Estimate input parameters for the picking process.

Total Time To Pick an Order Line From a Location(Seconds): 15

#Avg. Distinct Items in a Single-Item Order Batch: 30

#Avg. Distinct Items in a Multi-Item Order Batch: 20

#Avg. Unique Items in a Single Item Order Batch: To explain the parameter, let’s use a sample. Assume that we have 10 single-item orders. The order and SKU combination are shown below.

| Order | SKU |

| Order1 | A |

| Order2 | A |

| Order3 | B |

| Order4 | B |

| Order5 | C |

| Order6 | A |

| Order7 | C |

| Order8 | B |

| Order9 | D |

| Order10 | A |

Avg. number of consolidated item quantity for a single item picking job is calculated as below:

#Avg. Unique Items in a Single Item Order Batch= number of Orders/number of distinct SKUs = 10 / 4 = 2.5

This parameter is an estimation based on the number of active SKUs in the warehouse. If you have 100 active SKUs in the warehouse, the parameter may be 10 (It is not “1”, because the distribution of the SKUs will follow a normal distribution and the supply chain management system will try to consolidate similar SKUs into the same batch). If you have more SKUs for instance 1000 then the parameter may be 5.

#Avg. Unique Items in a Multi-Item Order Batch: We can use the same formula which we explained in the “#Avg. Unique Items in a Single Item Order Batch”. Usually, this parameter depends on the size of the picking batch and the number of active SKUs. You can test different values to estimate your average value.

Total Time To Pick From a Location(Seconds): This parameter may differ from one warehouse to another. It indicates the total time to walk between warehouse locations and to pick the products from the location. When a picker arrives at a location that is suggested by the warehouse inventory control WMS software, the user stops by and picks the products from the location. In this template, the walking duration from one location to another is included in the parameter.

Unlock a personalized tour of Logiwa IO

Calculated Values for Order Picking

These values are calculated automatically to estimate the duration of the order picking process.

Total Time to Execute a Single-Item Batch(Setup + Execution): 570 seconds

Total Time to Execute a Multi-Item Batch(Setup + Execution): 420 seconds

Total Time to complete a Single Item Batch: This value shows the total time required to execute a single item batch. And can be formulated as below:

Total Time = Setup time + (#Avg. Unique Items * Total Seconds To Pick From a Location)

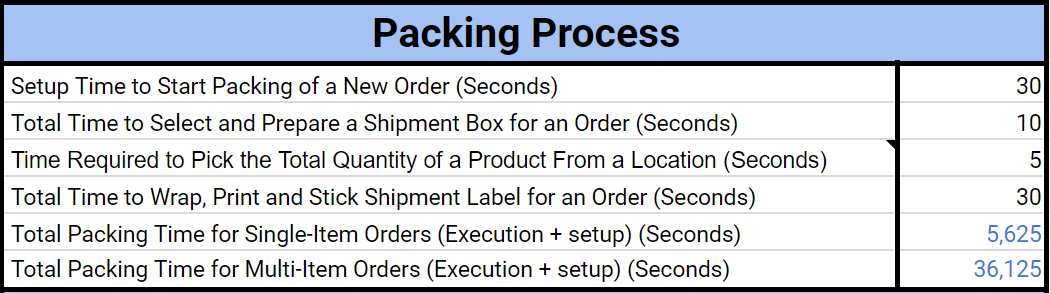

Order Packing Process

Setup Time to Start Packing of a New Order (Seconds): 30

Total Time to Select and Prepare a Shipment Box for an Order (Seconds): 10

Time Required to Pick the Total Quantity of a Product From a Location (Seconds): 5

Total Time to Wrap, Print and Stick Shipment Label for an Order (Seconds): 30

Setup time to start packing of a new order: The parameter indicates the time that is required to start the next packing task.

Total time to select and prepare a shipment box type for an order(Seconds): The parameter indicates the time that is required to check the products and select a suitable box type for shipment.

Time to scan an item and put it into the box: The parameter indicates the time that is required to pick an item from the tote, scan the barcode and locate it into the shipment box.

Total time to wrap, print and stick shipment label for order: The parameter indicates the time required to wrap the box, print a shipment label and mount label on the shipment box.

Calculated Values for Order Packing

These values are formulated to estimate the packing process.

Total Packing Time for Single-Item Orders (Execution + setup) (Seconds): 5,625

Total Packing Time for Multi-Item Orders (Execution + setup) (Seconds): 36,125

Total packing time for single item orders: This value shows the total time required to pack all the orders in a single item batch. The result is a function of setup time to start, box selection, product scanning, shipment labeling and wrapping.

Total packing time for multi-item orders: This value shows the total time required to pack all the orders in a multi-item batch. The result is a function of setup time to start, box selection, product scanning, shipment labeling and wrapping.

Results

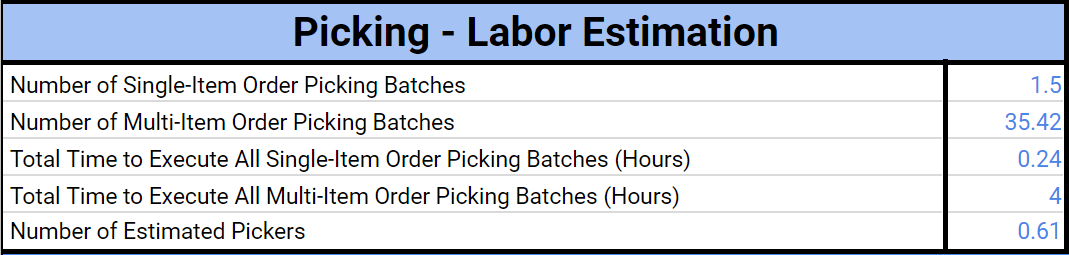

Results for Order Picking Process

This part of the sheet gives you a summary of the estimated results.

The number of single-item batch picking jobs: The value shows the number of single item order batches according to your daily shipment orders. This parameter uses the single item order percentage and the single item batch size to calculate the number of batches.

The number of multi-item batch picking jobs: The value shows the number of multi-item order batches according to your daily shipment orders. This parameter uses the multi-item order percentage( 1- Single Item Order percentage) and the multi-item batch size to calculate the number of batches.

Total time to execute single item batch picking jobs: This value shows the total hours to complete all the single-item batch orders.

Total time to execute multi-item batch picking jobs: This value shows the total hours to complete all the multi-item batch orders.

The Number of Pickers: This value shows the estimated number of pickers to pick the given shipment orders. The formula uses daily shift hours to estimate the total number of pickers. I did not round the numbers to give enough room for productivity in the warehouse. Usually, we round up the numbers.

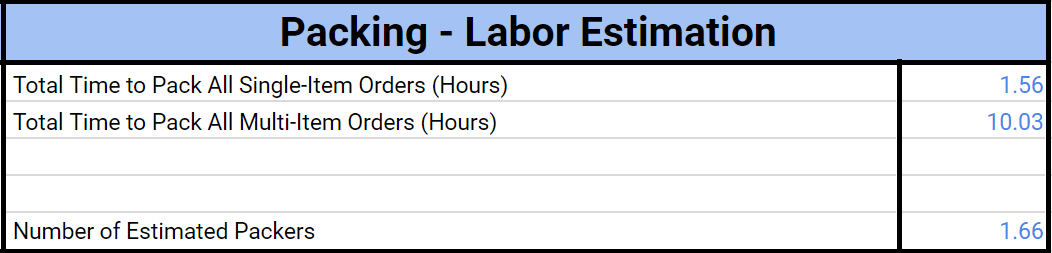

Results for Order Packing Process

This part of the sheet gives you a summary of the estimated results.

Total time to pack all single item orders: This value shows the total hours to complete all the single-item packing tasks.

Total time to pack all multi-item orders: This value shows the total hours to complete all the multi-item packing tasks.

Number of Packers: This value shows the estimated number of packers to pack the given shipment orders. The formula uses daily shift hours to estimate the total number of packers. I did not round the numbers to give enough room for productivity in the warehouse. Usually, we round up the numbers.

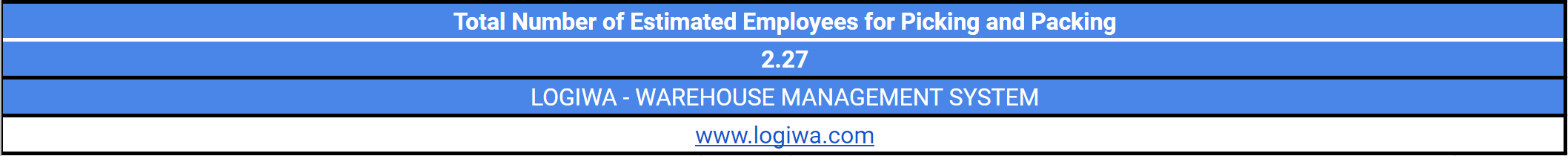

Number Of Estimated Labors

The last part of the sheet shows the estimated number of employees for picking and packing.

Conclusion

Successful warehouse labor planning is essential for effective warehouse operations, specifically in the areas of picking and packing. Leveraging tools like the spreadsheet discussed in this article can streamline the process and reduce bottlenecks, thereby increasing productivity and efficiency.

For even more advanced features and control over your warehouse labor planning, consider implementing a warehouse management system like Logiwa WMS. This powerful software provides robust tools to optimize labor allocation, batch processing, and much more. Explore the possibilities and maximize your warehouse performance with Logiwa WMS today.

FAQs: Warehouse Labor Planning

Q: What is warehouse labor planning?

A: Warehouse labor planning involves managing and organizing the workforce in a warehouse, specifically targeting tasks such as picking and packing. It aims to streamline the process and reduce bottlenecks, ultimately enhancing productivity and efficiency.

Q: How can I optimize single and multi-item order picking?

A: For single item orders, you can pick them in a batch, with a goal to reduce the number of locations visited per picking trip. For multi-item orders, using methods like cluster-based batch picking can be beneficial. The specifics of these processes may vary from one warehouse to another.

Q: What factors should I consider when deciding on picking batch size?

A: When deciding on picking batch size, you should consider the size of the picking car (or container) and the products in the batch. It’s generally better to have one picking car for a batch. Also, consider the total duration to execute all the batches, which should not be more than an hour. Furthermore, creating separate batches for large and small products can also be beneficial.

Q: How can I use a spreadsheet for warehouse labor planning?

A: A Warehouse Labor Planning spreadsheet can help you estimate labor time and cost. It allows you to define the essential parameters, such as daily shift hours, percentage of single-item orders, average items per multi-item order, and orders to be shipped daily. It also helps in calculating values for the order picking and packing processes.

Q: What is the role of a Warehouse Management System (WMS) in labor planning?

A: A Warehouse Management System (WMS), like Logiwa WMS, provides advanced features and control over your warehouse labor planning. It provides robust tools to optimize labor allocation, batch processing, and various other operations. With a WMS, you can further streamline processes and maximize your warehouse performance.