In the world of ecommerce, being able to meet demand is the ultimate test for online retailers. Luckily, inventory...

High-volume Order Fulfillment Blog

Cutting-edge industry trends and practical tips to make fulfillment excellence a competitive advantage

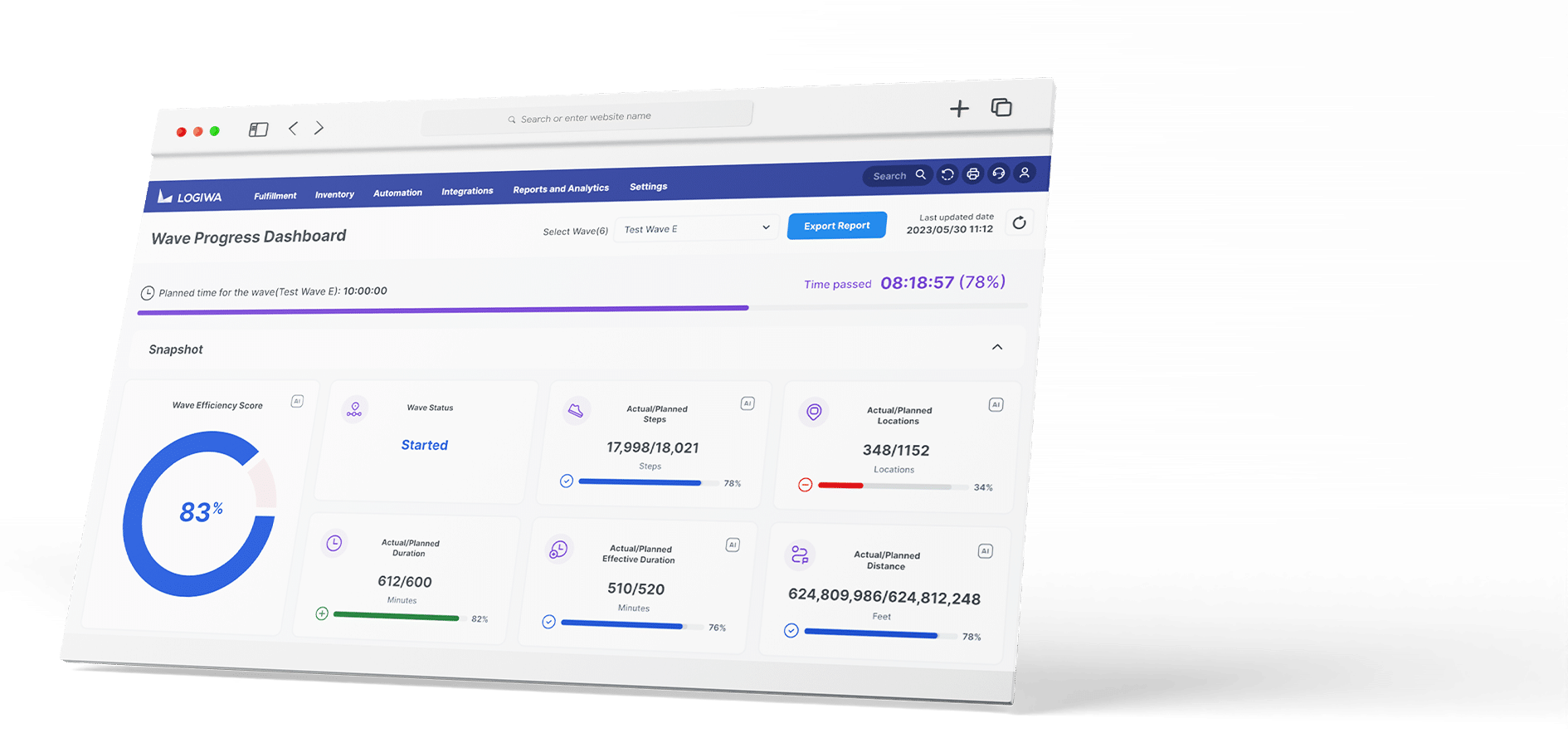

How AI labor optimization is changing the face of warehouse productivity

3PL WMS White Labeling

How To Scale Your Business Using 3PL White Labeling 3PL WMS services save companies time and money while enabling them...

The Power of Same Day Shipping for Global Fulfillment Services

To remain relevant in today’s ecommerce landscape, fast and convenient shipping is the only option. But not all...

The Sustainable Supply Chain: AI and Automation for a Green Warehouse

The concept of supply chain sustainability has changed ecommerce operations. It's influencing the choices of...

Warehouse Robotics and WMS Software: Everything You Need to Know

Dive into the world of warehouse robotics and warehouse management software (WMS) and discover how these technologies...

Amazon FBA vs FBM for Competitive Ecommerce Fulfillment

In the ever-expanding realm of ecommerce, where speed, efficiency and customer satisfaction reign supreme, choosing...

Material Handling 101: How to Keep Your Warehouse Productive With Warehouse Inventory Management Software

Dive into the comprehensive guide on material handling and learn how it can significantly boost productivity, enhance...

A Guide to Amazon FBA – Is Fulfillment by Amazon Right for You?

As the leading ecommerce platform in the world, Amazon offers services like Amazon FBA to help online sellers run...

Top Warehouse Management System Features for Your Fulfillment Network

Same- or next-day deliveries don’t just happen; they are the result of high-functioning fulfillment networks and...

How to Use Amazon’s FBA Calculator

Outsourcing logistics to a company like Amazon is a great option for tackling high-volume B2C and DTC operations, but...

9 Ways to Reduce Packaging Costs and Increase Profit

In this comprehensive guide, you will learn effective strategies to significantly reduce your packaging costs without...

Ecommerce Integration Technology for High-Efficiency Fulfillment Networks

Fulfillment and ecommerce integration technology has never been more important for online sellers, retailers and...